Communication Base Station-Infrastructure-ENERGROWTH

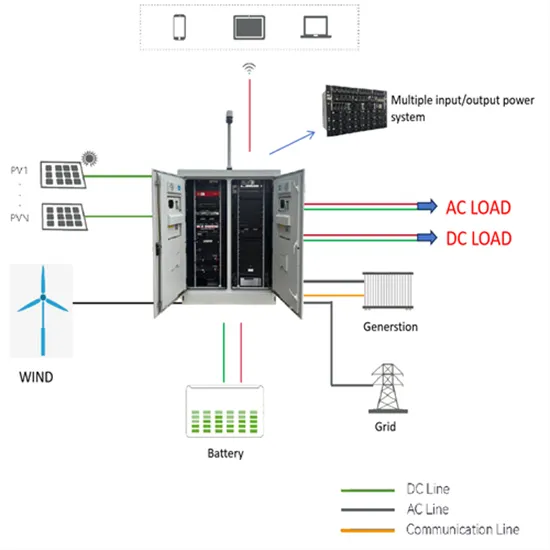

Communication Base Station A smart solution for a communication base station integrates advanced technologies to optimize performance, energy efficiency, and reliability.

Communication Base Station Cost Optimization: Navigating

As global 5G deployments accelerate, communication base station cost optimization has become the linchpin of telecom profitability. With operators spending $180 billion annually on network

Communication Base Station Lifecycle Cost | We Group E

As global 5G deployments accelerate, the communication base station lifecycle cost has emerged as a critical bottleneck. Did you know operators spend 65% more on maintaining 4G/5G hybrid

Guangzhou Kaixin Communication System Co., Ltd.

With its independently developed communication base station product series, the company supports customers in urban, suburban/rural signal coverage, subway/railway tunnels, urban

Emergency Communications Systems Value Analysis

Apr 1, 2020 · With all budgeting decisions, cost and value can be a trade-off. This document offers recommendations and a Value Analysis Checklist to assist public safety agencies make these

Simulation and Classification of Mobile Communication Base Station

Dec 16, 2020 · In recent years, with the rapid deployment of fifth-generation base stations, mobile communication signals are becoming more and more complex. How to identify and classify

Communication Base Station Financing Options | We

Have you ever wondered how telecom giants fund those towering communication base stations powering our digital world? With 5G deployment costs projected to hit $1.1 trillion globally by

Integrated Communication Base Station

Our solutions integrate base station environmental monitoring to optimize performance in extreme conditions, alongside adaptable mobile base station solutions for rapid deployment.

In-Depth Analysis of Base Station PCB Manufacturing Process

Mar 13, 2025 · In the era of advanced wireless communication, base station PCBs (Printed Circuit Boards) serve as the backbone of communication infrastructure, especially for 4G and 5G

Chapter 5 Communication Questions Flashcards | Quizlet

One role of the FCC in EMS communications systems is to a. purchase base-station radio equipment. b. license base stations. c. serve as a repeater for base-station operations. d.

6 FAQs about [Communication Base Station EMS Budget Company]

How much does an EMS business cost?

On average, staffing can account for over 50% of total EMS business expenses. Vehicle Maintenance and Fuel Costs: The operation of ambulances can incur yearly maintenance costs of around $5,000 to $10,000 per vehicle, with fuel expenses adding another $15,000 to $25,000 depending on the service area and frequency of calls.

How much does vehicle operation cost in an EMS business?

According to industry benchmarks, vehicle operation expenses typically account for approximately 10% to 15% of the total operating costs in an EMS business. This includes both regular maintenance and fuel costs. The type of vehicle used, frequency of use, and the terrain in which services are provided can all influence these figures significantly.

How much do emergency medical service providers spend on marketing & community outreach?

According to the National Association of Emergency Medical Technicians, on average, emergency medical service providers allocate about 6% of their operating budget for marketing and community outreach. It’s essential for companies like RapidMed Response to align their spending with these industry benchmarks to remain competitive.

What are the operating costs for emergency medical services?

In the realm of operating costs for an emergency medical service, one of the most significant and ongoing expenses is training and certification costs for medical personnel. It is essential for RapidMed Response to ensure that all staff are properly trained and certified to provide high-quality care in emergencies.

What are the most common EMS expenses?

Salaries and Wages for Medical Personnel: Personnel expenses often rank as one of the highest costs in any EMS business. On average, staffing costs can account for up to 50-60% of total operating expenses. This includes salaries for paramedics, EMTs, and administrative staff.

How can an EMS business save money?

The costs of running an EMS business can be drastically reduced through effective vehicle management. Implement a maintenance schedule that prevents costly repairs, which can save up to 30% on vehicle operation expenses. Use GPS and routing software to enhance efficiency in response times and fuel consumption.

Update Information

- 5g communication base station EMS equipment list

- Bissau Communication Base Station Battery Construction Company

- Open Source Communication Base Station Inverter Grid-Connected Company

- Communication base station EMS ambient temperature requirements

- Relocation of EMS communication base station

- Slovenia communication base station EMS equipment

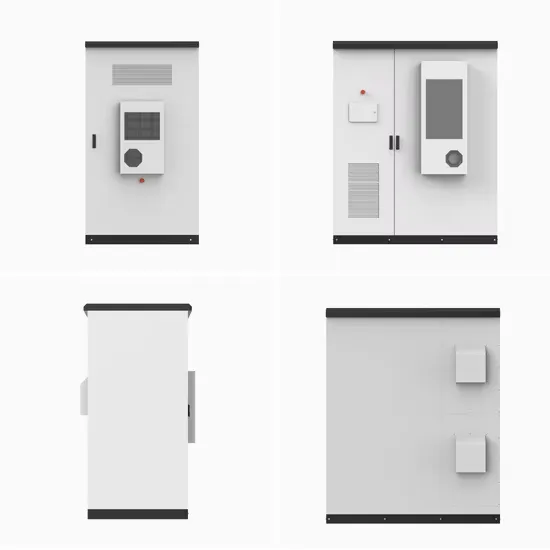

- BESS outdoor base station power supply communication BESS company

- Heqin Communication Technology Company 5g base station

- Egypt Communication Base Station Flywheel Energy Storage Construction Company

- Strengthening communication base station EMS

- Huawei Communication Base Station Inverter Grid-connected Equipment Company

- Cairo Communication Base Station Battery Lightning Protection and Grounding Company

- Which is the best solar power company for communication base station roof

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.