Modeling and analysis of liquid-cooling thermal

Sep 1, 2023 · Modeling and analysis of liquid-cooling thermal management of an in-house developed 100 kW/500 kWh energy storage container consisting of lithium-ion batteries retired

Containers for Thermal Energy Storage | SpringerLink

Feb 11, 2022 · PCMs plays a vital role in managing the supply and demand of the energy. The present work deals with the review of containers used for the phase change materials for

Blogs, News, Events

Jan 19, 2023 · The temperature control system is an important link to ensure the normal operation of lithium battery energy storage. At present, air cooling and liquid cooling technologies are the

How many degrees can an energy storage

Apr 10, 2024 · 1. Energy storage containers can store energy within a specific temperature range, usually between -20°F and 120°F. 2. The actual capacity

Design of a low-temperature rapid preheating system for an energy

The capacity ratio and low-temperature start-up battery group were calculated based on the capacity requirements of the energy storage container battery system, temperature boundary

Design of a low-temperature rapid preheating system for an energy

This study proposes a low-temperature rapid start-up scheme for mobile energy storage containers to address the problem of decreased emergency support capabilities caused by the

Airflow reorganization and thermal management in a

Nov 1, 2024 · The present paper numerically investigates the air-cooling thermal management in a large space energy storage container in which packs of high-power density batteries are

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · TLS OFFSHORE CONTAINERS /TLS ENERGY Battery Energy Storage System (BESS) is a containerized solution that is designed to store and manage energy generated

Temperature Prediction of a Temperature-Controlled

Jan 19, 2024 · In order to predict the variation of the thermal environment in a temperature-controlled container with a cold energy storage system, we propose an LSTM model based on

Climate Adaptation Innovation Of Container Energy Storage:

4 days ago · The widespread application of container energy storage worldwide requires it to be able to cope with extreme climates ranging from -50 ℃ to 50 ℃, from high humidity to high

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Apr 5, 2025 · Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Container energy storage battery temperature

LFP Battery Container Delta''''s LFP battery container is designed for grid-scale and industrial energy storage, with scalable capacity from 708 kWh to 7.78 MWh in a standard 10ft

Integrated cooling system with multiple operating modes for temperature

Mar 1, 2025 · The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Efficient Cooling System Design for 5MWh BESS Containers:

Aug 10, 2024 · Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Requirements for energy storage container layout

1. Requirements and specifications: - Determine the specific use case for the BESS container. - Define the desired energy capacity (in kWh) and power output (in kW) based on the

DESIGNING AN HVAC SYSTEM FOR A BESS CONTAINER:

Jun 8, 2023 · The Battery Energy Storage System (BESS) is a versatile technology, crucial for managing power generation and consumption in a variety of applications. Within these

Integrated cooling system with multiple operating modes for

Mar 6, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · However, as the core of energy storage systems, the temperature of lithium-ion batteries is a crucial factor affecting their performance and safety. Generally, the optimal

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · Research indicates that increasing the air supply angle enhances air mixing within the container and simultaneously decreases the battery pack surface temperature. With a 90°

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Liquid cooling addresses this challenge by efficiently managing the temperature of energy storage containers, ensuring optimal operation and longevity. By maintaining a

Study on uniform distribution of liquid cooling pipeline in container

Mar 15, 2025 · In large-scale grid energy storage systems, container-type BESS is generally used, which generally contains nine battery clusters, each battery cluster contains eight

Container energy storage battery temperature

1. What is the optimal design method of lithium-ion batteries for container storage? (5) The optimized battery pack structure is obtained, where the maximum cell surface temperature is

TLS ISO reefer & refrigerated container: Uses,

Jan 18, 2025 · TLS ISO reefer & refrigerated container: Dimensions, Uses, and Working Principles Refrigerated container (commonly referred to as "reefers")

6 FAQs about [Energy storage container temperature]

What is a containerized energy storage battery system?

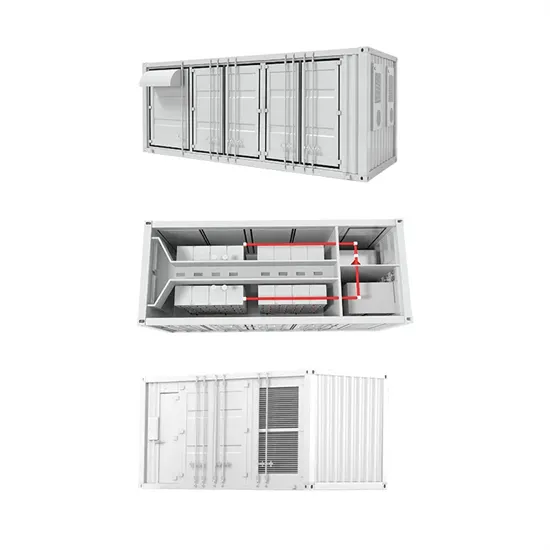

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

What are the different types of thermal energy storage containers?

Guo et al. [ 19] studied different types of containers, namely, shell-and-tube, encapsulated, direct contact and detachable and sorptive type, for mobile thermal energy storage applications. In shell-and-tube type container, heat transfer fluid passes through tube side, whereas shell side contains the PCM.

Are air cooling systems good for energy storage?

Air cooling systems, favoured for their low cost, simplicity, and space efficiency, are widely utilized in practical energy storage applications . However, they exhibit lower efficiency at high discharge rates and temperatures, resulting in uneven battery temperatures [16, 17].

Can a PCM container be used as a cold thermal energy storage system?

Appl Therm Eng 141 (June):928–938 Ghahramani Zarajabad O, Ahmadi R (2018) Employment of finned PCM container in a household refrigerator as a cold thermal energy storage system. Thermal Sci Eng Progress 7:115–124

How can thermal energy storage materials be encapsulated?

The considered thermal energy storage materials were encapsulated in a cylindrical copper tube and was placed between the glass cover and absorber plate. The combination of paraffin wax and granular carbon powder was observed to attain a thermal efficiency of 78.31%.

Which thermal energy storage materials are used in air heating systems?

Saxena et al. [ 89] experimentally investigated the thermal performance of an air heating system with three different thermal energy storage materials. The materials employed were granular carbon powder, paraffin wax and combination of both.

Update Information

- Energy storage container manufacturer ranking and price

- Approximate cost of Bin energy storage container

- Energy storage container solar photovoltaic module factory photothermal equipment

- Energy Storage Container Thermal Management System

- Energy storage container power station price inquiry

- Yaounde container energy storage system manufacturer

- Rwanda Prefabricated Energy Storage Container

- Which standard should energy storage container refrigeration meet

- Energy storage container wind turbine customization

- Photovoltaic power station energy storage container manufacturer

- Harare energy storage container installation manufacturer

- Ranking of Botswana container energy storage plants

- Bogota container photovoltaic energy storage

Solar Storage Container Market Growth

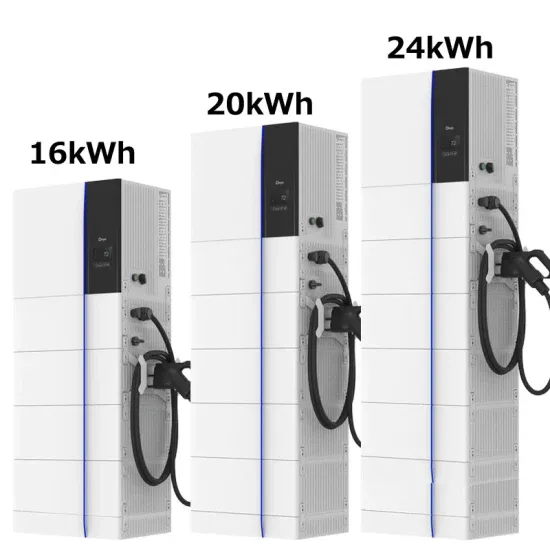

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.