BMS Protection Functions for Lithium Battery Pack

Sep 10, 2020 · Overvoltage Protection The voltage of a single cell in the battery pack exceeds the allowable voltage. According to the purpose of protection,

Battery protection selection guide

May 24, 2025 · For that, Infineon ofers a wide range of battery protection solutions that, under stressful conditions, increase lifetime and eficiency of lithium batteries. The battery protection

How To Protect 48-V Batteries from Overcurrent and

May 10, 2022 · For this design, a 48-V, 20-Ah lithium-ion battery was selected. Monitoring a 48-V lithium ion battery can be achieved using the TLV9022 device in combination with the TL431

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 11, 2024 · One Cell Lithium-ion/Polymer Battery Protection IC General Description The LN8231 provides a high integration solution for lithium-ion/polymer battery protection. The

Battery protection units (BPU) | Infineon Technologies

A battery protection unit (BPU) prevents possible damage to the battery cells and the failure of the battery, enhancing the useful operating life of lithium-ion batteries by protecting the battery

Protection Circuitry | Li-Ion & LiPoly Batteries

Jul 29, 2012 · If you want to take your project portable you''ll need a battery pack! For beginners, we suggest alkaline batteries, such as the venerable AA or 9V

How to Choose the Right Low Voltage Battery

Jun 18, 2023 · What is the difference between a low-voltage battery cutoff for a lead acid battery versus a lithium battery? The Low Battery voltage cutoff in

Lithium Battery Packs: Choosing the Protection Board Best

Aug 21, 2024 · The BQ77904 and BQ77905 devices are low-power battery pack protectors that implement a suite of voltage, current, and temperature protections without microcontroller

10s-16s Battery Pack Reference Design With Accurate

May 11, 2022 · Description This reference design is a low standby and ship-mode current consumption and high cell voltage accuracy 10s–16s Lithium-ion (Li-ion), LiFePO4 battery

Lithium Battery Pack Protection and Control

Safety and ageing concerns in Lithium battery applications highlight the critical need for advanced protection and control solutions in the market. Adoption of electric vehicles, both in the

Battery protectors

2 days ago · Get a short overview of system requirements to help you choose a battery protector, monitor or gauge. This reference design is a low standby and ship-mode current consumption

Understanding Lithium Battery Low Voltage

Mar 4, 2025 · Conclusion Understanding low voltage cutoff in lithium batteries is crucial for anyone who relies on these energy storage solutions. By preventing

Lithium-ion battery protection board and BMS knowledge

Use special lithium battery protection chip, when the battery voltage reaches the upper limit or lower limit, the control switch device MOS tube cut off the charging circuit or discharging

Lithium Battery Low Voltage Protection

Feb 25, 2020 · The low battery mode is usually enabled in lithium-ion cell products, like smartphones, thus, allowing them to power off, and at this point, even if the cell isn''t receiving

What Is Lithium Battery Protection Mode? | RELiON

There are 3 options to get your lithium battery out of low voltage protection mode: Option 1: Remove all load from the battery and wait for the battery voltage to recover high enough to

Li-Ion Battery Protection ICs

Feb 22, 2009 · The simplest protection method for battery packs is a fuse that opens if the system draws excessively high current. A more complex protection circuit is found in some battery

Lithium polymer battery protection technology:

Feb 14, 2025 · 1.Overcharge protection: prevent voltage overload One of the most serious risks of lithium polymer batteries is overcharging. When a lithium

6 FAQs about [Lithium battery pack low voltage protection]

How to protect a lithium battery?

Use special lithium battery protection chip, when the battery voltage reaches the upper limit or lower limit, the control switch device MOS tube cut off the charging circuit or discharging circuit, to achieve the purpose of protecting the battery pack. Characteristics: 1. Only over-charge and over-discharge protection can be realized.

What is a lithium battery protection circuit?

The protection circuit ensures the voltage does not exceed the safe limits set by the manufacturer. For example, a common lithium-ion battery operates between 3.0V and 4.2V per cell. Exceeding these limits can lead to serious safety risks like overheating, leakage, or even fires. A typical lithium battery protection circuit includes:

Do lithium batteries need a Protection Board?

Protection boards for lithium batteries offer monitoring protection. Low-voltage lithium batteries require a protection board. When using high-voltage lithium batteries, a battery management system (BMS) is typically chosen since these systems contain more functions for monitoring the state of the battery pack.

Do lithium batteries need a safety protection function?

Lithium battery applications are ubiquitous, but they require good management to ensure safe and reliable use, especially to prevent the voltage from dropping below the safety line, which we call over-discharge. This requires all batteries to have a safety protection function, which is low voltage cut-off protection, reviated as LVC.

What is a battery protection board?

Hardware-type protection board: Use special lithium battery protection chip, when the battery voltage reaches the upper limit or lower limit, the control switch device MOS tube cut off the charging circuit or discharging circuit, to achieve the purpose of protecting the battery pack. Characteristics: 1.

How can Tritek protect a lithium battery?

You can customize the protection requirements of various additional functions for your lithium battery, such as communication function, SOC calculation, SOH estimation, warning function, recording function, display function, etc. Tritek can provide your battery with a professional protection board and BMS.

Update Information

- The difference between high voltage lithium battery pack and low voltage lithium battery

- Irish low temperature lithium battery pack

- What is the charging voltage of a 24V lithium battery pack

- Lithium battery pack high voltage

- Low speed lithium battery pack wholesale

- Huawei lithium battery pack module automation

- Riga solar lithium battery pack usage

- 140w solar lithium battery pack

- Doha energy storage low temperature lithium battery

- The most durable lithium battery pack

- 18505 Lithium Battery Pack Specifications

- 482XH lithium battery pack

- Cylindrical lithium battery pack has good quality

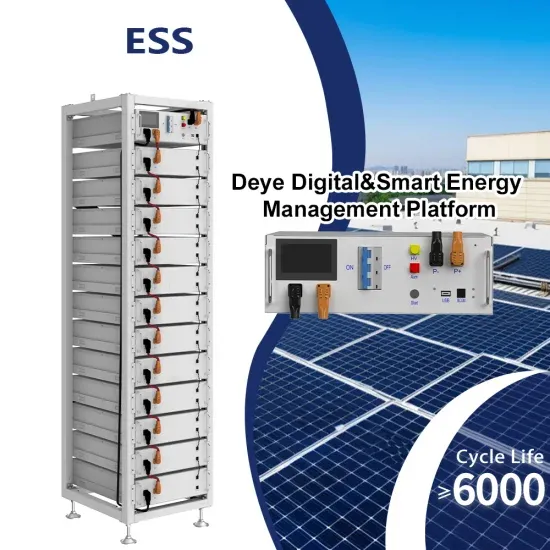

Solar Storage Container Market Growth

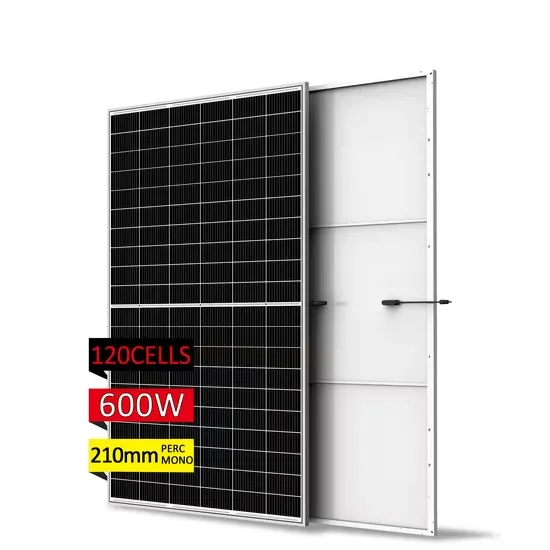

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.