Silicon Solar Cell Metallization and Module Technology

Chapters cover fundamentals of metallization and metallization approaches, evaporated, plated and screen-printed contacts, alternative printing technologies, metallization of specific solar

PV Cell Interconnection and Module Fabrication – S

Aug 29, 2024 · PV Cell Interconnection and Module Fabrication A bare single cell cannot be used for outdoor energy generation by itself. It is because (i) the output of a single cell is very small

PV Cell Interconnection and Module Fabrication – S

Aug 29, 2024 · Workable voltage and reasonable power are obtained by interconnecting an appropriate number of cells. Cells from same batch are used to make PV module. This is done

Lecture 17 Solar PV Cells Modules

Feb 25, 2020 · The short-circuit current is the current through the solar cell when the voltage across the solar cell is zero (i.e., when the solar cell is short circuited). The short-circuit current

Challenges for the interconnection of crystalline silicon

May 21, 2024 · In 2011 he joined Fraunhofer ISE in Freiburg as head of the PV modules group, focusing on interconnection technology for crystalline silicon solar cells, analysis of cell-to

Innovative Design-for-Recycling for Critical Material-Free

Jan 6, 2025 · In order to overcome these challenges, we present a module designed to facilitate recycling with no dispersive material consumption in interconnection while maintaining high

Fab & silicon heterojunction solar cells and modules

May 21, 2024 · Metallization and interconnection for silicon heterojunction solar cells and modules Matthieu Despeisse, Christophe Ballif, Antonin Faes & Agata Lachowicz, CSEM, Neuchâtel,

Patterning of organic photovoltaic modules by ultrafast

Besides inkjet print-ing, slot die and roller coating techniques were the most fre-quently demonstrated production methods. On the other hand, thin- lm PV modules require the

PVI17_Publishers_Foreword dd

May 21, 2024 · Back-contacted high-efficiency silicon solar cells – opportunities for low-cost metallization and cell interconnection Nils-Peter Harder, Agnes Merkle, Till Brendemühl,

Crystalline Silicon PV Module Technology

Jan 1, 2013 · Crystalline silicon module technology aims to turn solar cells into safe and reliable products, while maximizing efficiency. The chapter highlights fundamental challenges

Multi-busbar technology: Increased module power and

May 21, 2024 · This paper gives a summary of the benefits from a cell perspective, and an overview of the equipment for implementing the multi-busbar interconnection process, as well

The Anatomy of a Solar Cell: Constructing PV

Sep 30, 2024 · The number of cells connected in series determines the voltage of the module, while the number of parallel cell strings determines the current.

Silver-free intrinsically conductive adhesives for

May 15, 2024 · The accelerated growth of solar photovoltaics needed to reduce global carbon emissions requires an unsustainable amount of silver. Here,

Fraunhofer Institute for Solar Energy systems ISE

Nov 26, 2017 · Shingled Cell Interconnection: Aiming for a New Generation of Bifacial PV-Modules N. Klasen, A. Mondon, A. Kraft, U. Eitner Fraunhofer Institute for Solar Energy

Cell interconnection without glueing or soldering for

Here we present experimental results on an interconnection method of solar cells, which permits higher power output per module area and may also lower production costs. Some preliminary

Sequential thermomechanical stress and cracking analysis of

Dec 1, 2024 · In recent years, with the development of PV module manufacturing industries, module manufacturers have developed many new technologies to improve the power

Silicon back contact solar cell configuration: A pathway

Jul 1, 2016 · This co-planar cell interconnection simplifies the module fabrication process, allowing for thinner and larger wafers to be used, eventually reduces the module manufacturing costs

Innovative Cell Interconnection Based on Ribbon Bonding of

Apr 1, 2015 · Attaching interconnection ribbons to solar cells using electrically conductive adhesives is an attractive alternative to soldering, particularly if it can be achieved on cells

Challenges for the interconnection of crystalline silicon

May 21, 2024 · Currently, there exist three approaches for the interconnection of HJT solar cells, each with its own strengths and weaknesses: 1) ribbon soldering with low-melting-point alloys;

A review of interconnection technologies for improved crystalline

Sep 15, 2015 · Current interconnection technologies of crystalline Si solar cells are evaluated. Technology inducing least stress while supporting PV manufacturing trend is optimal. Laser

Understanding the cell-to-module efficiency gap in Cu

Jun 8, 2018 · Here, Bermudez and Perez-Rodriguez review the origins of the cell-to-module gap and the solutions proposed to enable the scale-up of this photovoltaic technology.

Industrialization of Ribbon Interconnection for Silicon

Sep 12, 2019 · ABSTRACT: The use of electrically conductive adhesives (ECAs) and ribbons is a cost-efficient solution for the inter-connection of silicon heterojunction (SHJ) solar cells already

Busbar-free electrode patterns of crystalline silicon solar cells

Aug 15, 2022 · Accordingly, we focused on reducing the consumption of Ag paste used for the metallization of solar cells by designing busbar-free electrode patterns suitable for shingled

6 FAQs about [Photovoltaic module cell interconnection structure]

What is a solar PV module?

Solar PV ModuleSolarPV moduleA solar PV module is a device in which several solar cells are connected toget m2 ,Cell efficiency - 10 to 25% )• This power is not enough for home lig ModuleArrayCellSolar PV array de MW.IPV V module__Interconnection of solar cells into solar PV modules

How do solar cells interconnect in crystalline silicon modules?

The interconnection of solar cells in crystalline silicon modules by soldering process is a high temperature process which occurs at about 250 °C. The elevated temperature soldering induces thermo-mechanical stress in the solder joints.

Which interconnection technology is best for crystalline Si solar cells?

Current interconnection technologies of crystalline Si solar cells are evaluated. Technology inducing least stress while supporting PV manufacturing trend is optimal. Laser soldering is identified as most efficient PV cell interconnection technology. Laser soldering is poised for use to extend MTTF of modules operating in tropics.

Does interconnection technique increase PV module power output?

Schneider A, Rubin L, Rubin G, Ospov A, Smirnov A, Antipov P. A new approach in solar cell module interconnection technique resulting in 5–10% higher PV module power output. In: Conference record of the IEEE 4th world conference on photovoltaic energy conversion, Waikoloa (HI); 2006. Köntges M, Gast M, Brendel R, Meyer R, Giegrich A, Merz P.

How are solar cells interconnected?

The concept involves interconnecting solar cells on a patterned back sheet foil using conductive adhesives or low melting point solders . Table 2 presents a comparison of interconnection technologies employed in the manufacture of silicon solar cells including thin-film silicon solar cells.

How to solve interconnection challenges with unconventional PV modules?

In order to address the interconnection challenges, many unconventional PV modules with improved interconnection have been developed. Their interconnect concepts include back contact cells technology. In this technique, the interconnection materials and circuitry are located exclusively behind the cells.

Update Information

- Photovoltaic cell module grade

- What is the cell of photovoltaic module obb

- Argentina photovoltaic cell module manufacturer

- Which photovoltaic cell module is better

- Polycrystalline 280w photovoltaic cell module unit price

- Photovoltaic cell module layout

- Photovoltaic energy storage inverter structure

- Photovoltaic module prices in Kathmandu

- N-type 580wp crystalline silicon photovoltaic module price

- Germany Hamburg photovoltaic module inverter company

- Single-row photovoltaic module price

- Photovoltaic double-glass module back connector

- N Djamena polycrystalline photovoltaic module glass

Solar Storage Container Market Growth

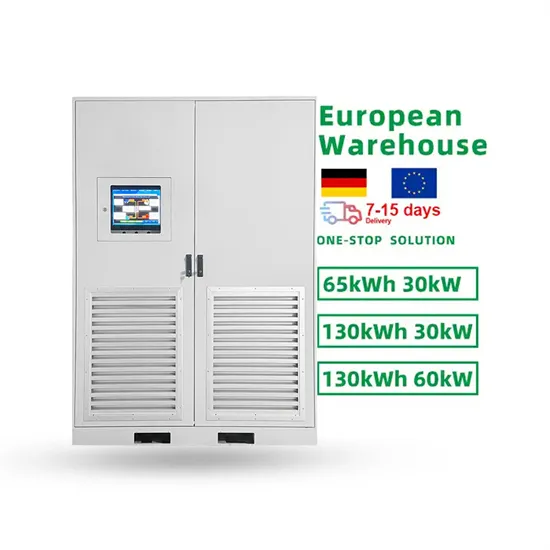

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.