Lecture 17 Solar PV Cells Modules

Feb 25, 2020 · The short-circuit current is the current through the solar cell when the voltage across the solar cell is zero (i.e., when the solar cell is short circuited). The short-circuit current

Cell string layout in solar photovoltaic collectors

Oct 1, 2017 · Several solar cell string configurations in the photovoltaic modules are simulated using a simulation program for integrated circuits, looking for a mitigation of the effects of

Physical models used > PV Module

Nov 7, 2024 · Electrically, these modules are made of 2 sets of 3 strings of half-cells, mounted in parallel. Each pair of string shares the same by-pass diode. In the PV modules definition

Photovoltaic Cell String Layout

Nov 29, 2024 · Stationary solar concentrating hybrid PVT systems use reflectors, which may cause non uniform distribution of light on the string of PV cells. Similarly, partial shading

Calculation & Design of Solar Photovoltaic Modules & Array

Sep 10, 2022 · Algorithm for the optimal PV modules layout on irregular rooftop is presented. Building components and irregular roof shapes are considered in the research. The influence

MANUFACTURING OF SOLAR PANELS: FROM CELL TO

Nov 22, 2022 · Here we have emphasized on complete panel manufacturing process viz. Manufacturing of PV Cell, different types of PV Cell, Solar Panels, Testing of Solar Panels,

A general algorithm for the optimization of photovoltaic modules layout

Sep 10, 2022 · The optimal photovoltaic module layout obtains the maximum energy gain of 27.83% with respect to the Jacobson''s equation and the minimum of 24.84% with respect to

Photovoltaics: Basic Principles and Components

Oct 14, 2013 · Introduction to PV Technology Single PV cells (also known as "solar cells") are connected electrically to form PV modules, which are the building blocks of PV systems. The

Spatial layout optimization for solar photovoltaic (PV) panel

May 1, 2020 · Layout design maximizes the energy production potential of a solar PV system. The new method has been applied to identify the optimal panel layout on a rooftop. Flexible panel

The effect of shading on photovoltaic solar panels

Nov 23, 2016 · A modelling description of photovoltaic (PV) modules in a PSPICE environment is presented. To validate the simulation model, a lab prototype is used to create similar

6 FAQs about [Photovoltaic cell module layout]

What is a solar PV module?

Solar PV ModuleSolarPV moduleA solar PV module is a device in which several solar cells are connected toget m2 ,Cell efficiency - 10 to 25% )• This power is not enough for home lig ModuleArrayCellSolar PV array de MW.IPV V module__Interconnection of solar cells into solar PV modules

What is a PV cell & module?

A single PV device is known as a cell, and these cells are connected together in chains to form larger units known as modules or panels. Research into cell and module design allows PV technologies to become more sophisticated, reliable, and efficient.

How to arrange solar modules in a photovoltaic power station?

There are two ways of arranging solar modules in photovoltaic power stations, horizontal and vertical. Horizontal means that the long side of the solar module is parallel to the east-west direction, while vertical means that the short side is parallel to the east-west direction. Whether to use horizontal or vertical depends on different situations.

What are the basic requirements of a solar PV module?

One of the basic requirements of the PV module is to provide sufficient voltage to charge the batteries of the different voltage levels under daily solar radiation. This implies that the module voltage should be higher to charge the batteries during the low solar radiation and high temperatures.

Which modules can be used for module layout calculation?

In the present state, only the traditional modules (in width or in Length) and the Twin half-cut cells modules have been implemented. We can also apply the Module Layout calculation to the twin third-cut cells with 5 rows, with a very good approximation. All other structures are not suited for the Module Layout calculation.

How many volts a PV module can charge a battery?

A typically designed PV module has a VM of 15 V to charge a battery of 12 V. To obtain this voltage 32 to 36 cells are connecting in series depending upon their operating temperature and peak voltage VM of an individual cell.

Update Information

- What is the cell of photovoltaic module obb

- Which photovoltaic cell module is better

- Photovoltaic module cell processing platform

- Polycrystalline 280w photovoltaic cell module unit price

- 570 Photovoltaic Module Price

- Black Mountain photovoltaic module equipment price

- Number of photovoltaic module cells

- Beirut Photovoltaic Module Project

- Peru Photovoltaic Module Project

- Photovoltaic inverter communication module

- Maldives photovoltaic module inverter manufacturer

- Layout of photovoltaic inverter and combiner box bridge

- Andorra solar photovoltaic module customization

Solar Storage Container Market Growth

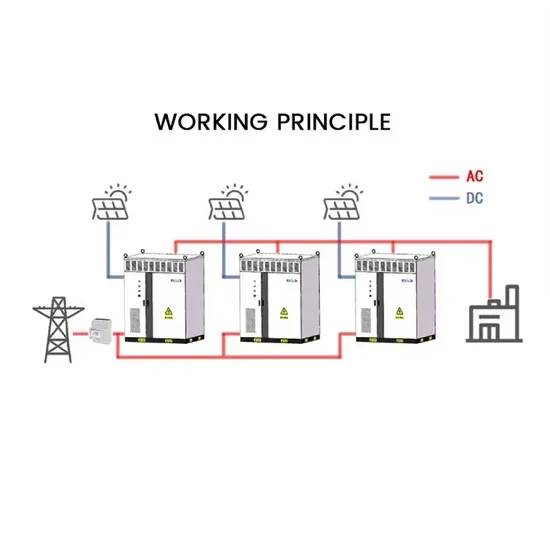

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.