A high-power inverter based technology

Mar 20, 2024 · Efficiency increase: CO2 emission reduction Power density: smaller and lighter power unit form factor Cost reduction: system level cost reduction or lower TCO

What Does An Inverter Do? Complete Guide To

Jul 8, 2025 · Learn what inverters do, how they convert DC to AC power, types available, and applications. Complete guide with sizing tips, safety advice, and

Design Priorities in EV Traction Inverter With Optimum

Apr 1, 2023 · Weight and power density – The wide band-gap switch and powertrain integration are the key technologies enabling high-power density inverter design. The inverter power

Bus Bar Design for High-Power Inverters

Apr 6, 2017 · This paper presents a comprehensive analysis about bus bar design procedure. Some applications in terms of rated power and shape are investigated regarding their

Reversible High-Power Three-Phase DC/AC Inverter Family

BrightLoop''s three-phase DC/AC reversible inverters are ideal for stationary power backup systems, on-board chargers (OBCs) for heavy-duty vehicles, or AC grid feeding.

Considerations on the Development of High-Power Density

Jan 14, 2024 · In transportation electrification, power modules are considered the best choice for power switches to build a high-power inverter. Recently, several studies have presented

Development of high power SiC devices for rail traction power

Feb 1, 2019 · High voltage power modules are mainly used for the main inverter to handle the high power and working in harsh conditions with high switching frequency and varying load profiles.

Automotive, High-Power, High-Performance SiC Traction

May 5, 2025 · Automotive, High-Power, High-Performance SiC Traction Inverter Reference Design Description This reference design is an 800V, 300kW silicon carbide (SiC) based

Discover the Sunny Highpower PEAK3 | SMA America

SMA offers the ONLY 1500 VDC inverter, the PEAK3 125 kW, with the capability to interconnect at 480 VAC without requiring significant additional equipment or sacrificing energy production.

HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · The high-power switches are the most critical component in the inverter as they control the flow of current to the motor to generate motion. As such, the switches'' are

Thermal analysis of Si-IGBT based power electronic modules

Mar 1, 2023 · High power density traction inverter requires a new approach to cope with the stringent reliability requirements. The junction temperature of Si IGBT must be kept below 125

Electric converters, motors and systems

HV inverters High-voltage inverters convert direct current (DC) from batteries or generators to alternating current (AC) to power motors or other devices. Our inverters support a variety of

Immersion cooling for high-power inverters: a highlight from

Titled "Design and Development of a High-Power Density Inverter Using Dielectric Oil Immersion Cooling", the paper by Alexandre Battiston, Hakim El Bahi, and their team demonstrates a

Bus Bar Design for High-Power Inverters

Sep 19, 2017 · Simulated results are compared with measurements by a high precision impedance analyzer which shows the reliability of 3D modeling-based designs. Index

New medium-voltage inverter design with very high power

Jun 19, 2008 · The three-level NPC VSC topology and press-pack IGBT (PPI) devices are the key technologies for high-power medium-voltage (MV) drives. In this paper, a novel de

High-precision Power Measurement of SiC Inverters

Jan 16, 2023 · Accurate power measurement is a critical precondition for eval-uating motor drive systems, but power measurement of SiC inverters requires high-precision measurement

HEV/EV Traction Inverter Design Guide Using Isolated

Apr 1, 2023 · Zooming in to the traction inverter system reveals multiple blocks including the power management IC (PMIC) and the microcontroller (MCU), the high-power IGBT or SiC

TOPIC: Power inverters and converters. Basic Electricity

Oct 8, 2023 · Power inverters are primarily used in electrical power applications where high currents and voltages are present; circuits that perform the same function for electronic

6 FAQs about [High Power Mechanical Inverter]

What is a high power switch in an inverter?

The high-power switches are the most critical component in the inverter as they control the flow of current to the motor to generate motion. As such, the switches' are monitored and protected by sensing their temperature, voltage and current throughout their operation.

Who is hzinverter?

Professional Inverter Manufacturer HzInverter sells high quality Inverter Boards, Modified Sine Wave Inverters, Pure Sine Wave Inverters and Solar Inverters worldwide. Our team is constantly developing and innovating to provide reasonable and efficient solutions for customers from different countries and regions.

What is the best distributed generation inverter?

Your Distributed Generation Inverter. Ideal for Community Solar, Agrivoltaics, Floating PV, Small Utility and Data Center projects. Engineered for performance, the PEAK3 delivers unmatched power density in a compact, lightweight design—reducing transportation costs and simplifying installation.

Which inverter is best for repowering large-scale PV plants?

Repowering Ready: The PEAK3 FLEX offers best in class flexibility in a modular architecture that achieves a universal solution for repowering large-scale PV plants. SMA offers the ONLY 1,500 VDC inverter with the capability of interconnecting at 480 VAC without adding significant additional equipment and incurring lost energy production.

Which SMA inverter is best?

SMA offers the ONLY 1,500 VDC inverter with the capability of interconnecting at 480 VAC without adding significant additional equipment and incurring lost energy production. For large ground mount projects, SMA’s PEAK3 delivers the most costeffective solution and highest energy production. Which is the best layout for a large-scale PV power plant?

What is a peak3 inverter?

PEAK3 stands for pure power. With its compact design, the inverter offers the highest power density per device. The advantages: optimal performance at a light weight. The result is cheaper transportation and easier installation. In combination with the project-specific DC Combiner Boxes, the PV array can be oversized up to 200 %.

Update Information

- Inverter high power ground pin

- Sri Lanka High Frequency Power Inverter

- Inverter high power rear stage

- Inverter high power car servant

- Nairobi High Power Inverter Manufacturer

- Brussels photovoltaic power station high quality inverter

- Inverter Type High Frequency Power Frequency

- Dominic high power inverter

- Household inverter high power

- The inverter outputs high voltage with excess power

- Austria high frequency power inverter

- High power inverter

- High voltage power supply full bridge inverter price

Solar Storage Container Market Growth

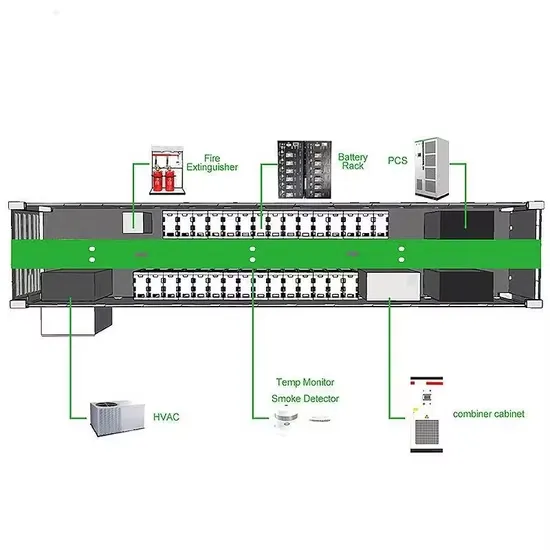

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.