Lithium-ion Battery – How it works – Electricity –

Feb 23, 2025 · The fundamental principle in an electrochemical cell is spontaneous redox reactions in two electrodes separated by an electrolyte,

A review of porous electrode structural parameters and

Sep 1, 2024 · Redox flow batteries (RFBs) have emerged as promising and highly scalable technologies for durable energy storage systems. The porous electrode, as a vital component

Recent development of electrode materials in semi-solid lithium

Jan 15, 2024 · SSLRFBs represent a promising energy storage technology that combines the advantages of flow batteries and lithium-ion batteries. The use of semi-solid electrodes and

How lithium-ion batteries work conceptually:

Feb 26, 2024 · We analyze a discharging battery with a two-phase LiFePO 4 /FePO 4 positive electrode (cathode) from a thermodynamic perspective and show that, compared to loosely

A three-dimensional flow-electrochemistry coupling model

Apr 1, 2024 · Although unlike lithium-ion batteries, the active component of the slurry battery is not fixed but mixed with the electrolyte and flows continuously, the static flow channel as a whole

Advanced electrode processing for lithium-ion battery

Feb 3, 2025 · High-throughput electrode processing is needed to meet lithium-ion battery market demand. This Review discusses the benefits and drawbacks of advanced electrode

High-performance Porous Electrodes for Flow

Oct 2, 2024 · Porous electrodes are critical in determining the power density and energy efficiency of redox flow batteries. These electrodes serve as platforms

REACTIVE FLOW IN LARGE-DEFORMATION ELECTRODES OF LITHIUM-ION BATTERIES

Aug 5, 2025 · An electrode in a lithium-ion battery may undergo inelastic processes of two types: flow and reaction. Flow changes the shape of the electrode, preserves its composition and

CHAPTER 3 LITHIUM-ION BATTERIES

Sep 3, 2021 · A Li-ion battery is composed of the active materials (negative electrode/positive electrode), the electrolyte, and the separator, which acts as a barrier between the negative

Intensified flow and mass transfer in lithium slurry redox flow

May 1, 2025 · Lithium slurry redox flow batteries (SRFBs) are regarded as one of the most promising long-duration electrochemical energy storage technologies as they combine the

Electrochemical reactions coupled multiphysics modeling for lithium ion

Feb 1, 2024 · During high-rate discharging process of lithium-ion battery (LIB), the macroscopic models struggle to capture the actual three-dimensional spatial evolutions of physical fields. In

Reaction kinetics inside pore spaces in lithium-ion battery

Feb 20, 2023 · That is, in the analysis of the electrode reaction in the present study, a three-electrode cell (working electrode (diameter: 2 mm, thickness: 69 μm, LiCoO2), counter

Side Reactions/Changes in Lithium-Ion Batteries:

May 2, 2024 · Abstract Lithium-ion batteries (LIBs), in which lithium ions function as charge carriers, are considered the most competitive energy storage

Revealing the Real Electrode Reaction Process of Lithium-Ion Batteries

May 28, 2025 · Nonuniform reactions within porous electrodes are a common phenomenon during the charge–discharge processes of lithium-ion batteries, significantly impacting their rate

Electrode–Electrolyte Interface in Li-Ion Batteries:

Oct 29, 2015 · Understanding reactions at the electrode/electrolyte interface (EEI) is essential to developing strategies to enhance cycle life and safety of lithium

Advanced electrode processing for lithium-ion battery

Feb 3, 2025 · In this Review, we discuss advanced electrode processing routes (dry processing, radiation curing processing, advanced wet processing and 3D-printing processing) that could

Electrode materials for lithium-ion batteries

Dec 1, 2018 · This mini-review discusses the recent trends in electrode materials for Li-ion batteries. Elemental doping and coatings have modified many of the commonly used electrode

6 FAQs about [Lithium-ion flow battery electrode reactions]

Why do lithium ions flow from a negative electrode to a positive electrode?

Since lithium is more weakly bonded in the negative than in the positive electrode, lithium ions flow from the negative to the positive electrode, via the electrolyte (most commonly LiPF6 in an organic, carbonate-based solvent20).

What is a lithium-ion battery reference electrode?

Soc. 172 013507 DOI 10.1149/1945-7111/ada7a4 A lithium-ion battery reference electrode applicable to both laboratory and onboard vehicle use provides a high level of understanding of electrochemical processes within a cell and enables highly sophisticated, real-time electrode control that maximizes cell utilization, life, safety, and overall value.

Do lithium-ion batteries have a nonuniform reaction?

Revealing the Real Electrode Reaction Process of Lithium-Ion Batteries by Coupling Kinetics and Thermodynamics Nonuniform reactions within porous electrodes are a common phenomenon during the charge–discharge processes of lithium-ion batteries, significantly impacting their rate performance.

What happens when a lithium ion is charged?

The solvent or lithium salt is reduced or oxidized at the surface of the electrode during charging, and a portion of the resulting substance that is insoluble in the electrolyte will be deposited on the surface of the negative electrode or the positive electrode (Goodenough and Kim, 2010).

What is advanced lithium-ion battery electrode processing?

Conventional lithium-ion battery electrode processing heavily relies on wet processing, which is time-consuming and energy-consuming. Compared with conventional routes, advanced electrode processing strategies can be more affordable and less energy-intensive and generate less waste.

How do lithium-ion batteries work?

A good explanation of lithium-ion batteries (LIBs) needs to convincingly account for the spontaneous, energy-releasing movement of lithium ions and electrons out of the negative and into the positive electrode, the defining characteristic of working LIBs.

Update Information

- Flow battery construction area

- Lisbon communication base station flow battery construction project bidding

- Uzbekistan Ronghe No 1 liquid flow battery

- Danish communication base station flow battery maintenance project

- Vanadium Redox Flow Battery Maintenance

- New Delhi Liquid Flow Battery Brand Ranking

- Israel communication base station flow battery cabinet in stock

- Liquid Flow Battery Energy Storage Container

- Liquid Flow Battery Industrial Park

- Liquid Flow Energy Storage Battery Project

- What does the flow battery for communication base stations do

- South Korea communication base station flow battery lightning protection

- Leading enterprise of vanadium liquid flow energy storage battery

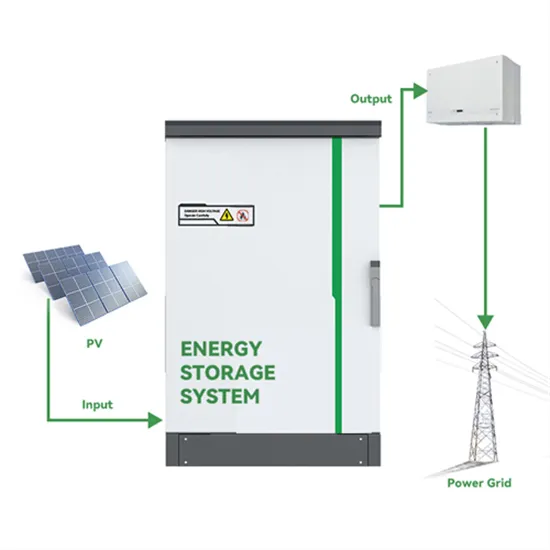

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

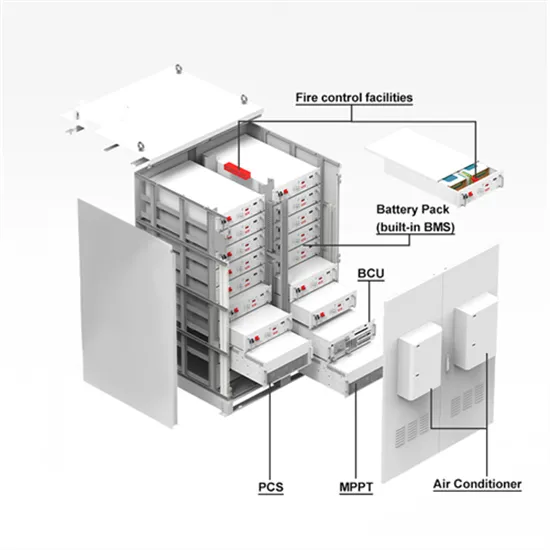

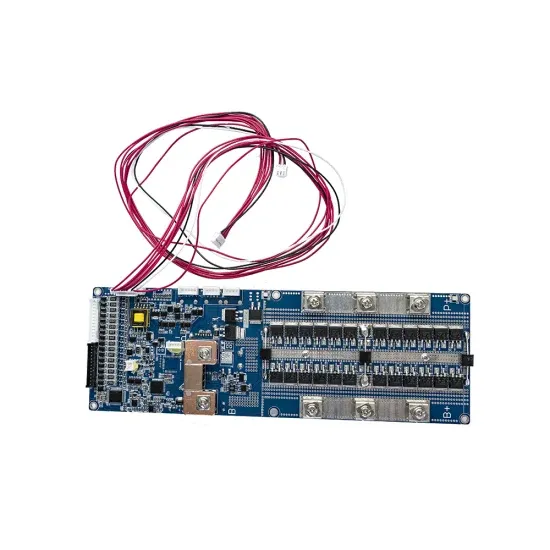

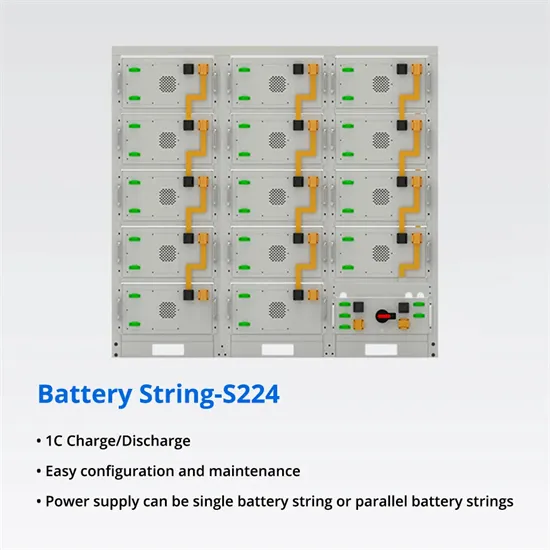

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.