Tesla Solar Inverter and Solar Shutdown Device Datasheet

Oct 25, 2024 · Solar Shutdown Device Technical Specifications — The Solar Shutdown Device is a Mid-Circuit Interrupter (MCI) and is part of the PV system rapid shutdown (RSD) function in

SolarEdge Inverters: Complete Guide to Models,

Jul 15, 2025 · Comprehensive guide to SolarEdge inverters covering all models, performance testing, pricing, and installation. Independent analysis with real

Photovoltaic inverter technical specifications

Inverter Transformers for Photovoltaic (PV) power plants: Generic guidelines 2 Abstract: With a plethora of inverter station solutions in the market, inverter manufacturers are increasingly

Tesla Powerwall+ Datasheet

Sep 12, 2022 · P O W E R WALL+ Powerwall+ is an integrated solar battery system that stores energy from solar production. Powerwall+ has two separate inverters, one for battery and one

TECHNICAL SPECIFICATIONS OF ON-GRID SOLAR PV

Feb 3, 2021 · The inverter shall include appropriate self-protective and self-diagnostic feature to protect itself and the PV array from damage in the event of inverter component failure or from

TECHNICAL SPECIFICATIONS OF HYBRID SOLAR PV

Feb 3, 2021 · 3. DEFINITION A Hybrid Solar PV power plant system comprises of C-Si (Crystalline Silicon)/ Thin Film Solar PV modules with intelligent Inverter having MPPT

Solar Hybrid Inverter Manufacturers, Grid Interactive Inverter

NingBo Deye Inverter Technology Co.,Ltd is famous hybrid inverter manufacturers and grid interactive inverter suppliers, we offer hybrid inverter with solar battery charging.

Powerwall 3 Datasheet

Apr 24, 2025 · Solar Shutdown Device Technical Specifications The Solar Shutdown Device is a Mid-Circuit Interrupter (MCI) and is integral to the rapid shutdown (RSD) function required for

Solar Inverter Specifications

Apr 3, 2025 · The following specifications reflect Tesla Solar Inverter with Site Controller (Tesla P/N 1538000-45-y). For specifications on Tesla Solar Inverter without Site Controller, see

Solar Photovoltaic: SPECIFICATION, CHECKLIST AND GUIDE

Aug 14, 2012 · The specifications were developed with significant input from stakeholders including policymakers, code officials, solar installers, and successful RERH builders. The

6 FAQs about [PV inverter model specifications]

What are inverter specifications?

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the inverter data sheet. Maximum AC output power This is the maximum power the inverter can supply to a load on a steady basis at a specified output voltage.

What is a Tesla Solar inverter?

Tesla Solar Inverter completes the Tesla home solar system, converting DC power from solar to AC power for home consumption.

What is a flexinverter solar inverter?

The FLEXINVERTER Solar Inverter is one of the is one of the industry’s leading 1500V developments and is GE’s latest evolution in renewable power electronics. Building on expertise in the renewables industry, GE now offers its latest power conversion technology for efficient, cost effective and dispatchable solar power.

How much power does an inverter need?

It’s important to note what this means: In order for an inverter to put out the rated amount of power, it will need to have a power input that exceeds the output. For example, an inverter with a rated output power of 5,000 W and a peak efficiency of 95% requires an input power of 5,263 W to operate at full power.

How do you classify an inverter based on its power output?

Using the CEC efficiency, the input power to the inverter must be PIN=POUT/CEC Efficiency=3,300 W/0.945=3,492 W Inverters can be classed according to their power output. The following information is not set in stone, but it gives you an idea of the classifications and general power ranges associated with them.

Which PCU/Inverter should be used in a power plant?

IP-20(Minimum) for indoor. IP-65(Minimum) for outdoor. (a) Three phase PCU/ inverter shall be used with each power plant system (10 kW and/or above) but in case of less than 10 kW single phase inverter can be used. (b) PCU/inverter shall be capable of complete automatic operation including wake-up, synchronization & shutdown.

Update Information

- Venezuela Three PV Inverter Sales

- Whether to use PV string inverter

- Mbabane PV panel inverter manufacturer

- Castrie PV Module Inverter Manufacturer

- Tskhinvali PV inverter costs

- Cyprus PV Off-Grid Inverter

- High voltage inverter model

- PV 330 inverter size

- Guatemala PV water pump inverter recommendation

- Mali PV grid-connected inverter selection

- PV inverter rated capacity

- Peru PV Power Station Inverter

- Inverter power specifications

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

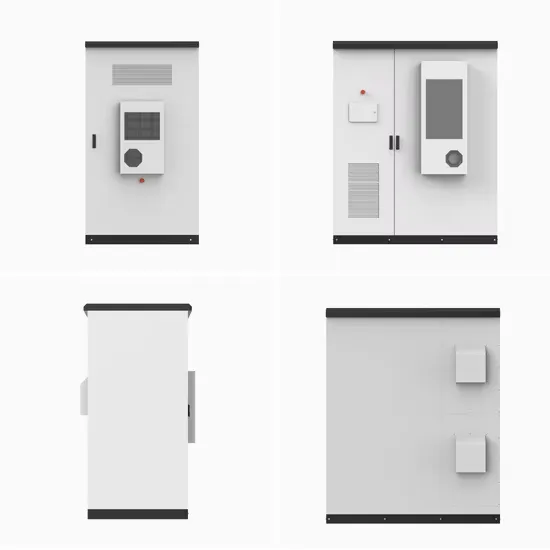

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.