Optimized Heat Dissipation of Energy Storage Systems

Sep 23, 2020 · Optimized Heat Dissipation of Energy Storage Systems The quality of the heat dissipation from batteries towards the outer casing has a strong impact on the performance

Ultra-thin vapour chamber based heat dissipation

Mar 15, 2024 · A powerful thermal management scheme is the key to realizing the extremely fast charging of battery electric vehicles. In this scheme, a water-cooled plate is set at the bottom

Heat dissipation investigation of the power lithium-ion battery

Nov 15, 2020 · In this work, the physical and mathematical models for a battery module with sixteen lithium-ion batteries are established under different arrangement modes based on the

Highly thermal conductivity phase change composites

Jul 15, 2025 · Phase change composites (PCCs) for the thermal management of high-energy density device are required to have large heat storage capacity and rapid heat conduction and

Mitigation of Heat Propagation in a Battery Pack by

The use of pyrolytic graphite sheets (PGS) with high thermal conductivity has successfully been employed for transporting heat out of the bat- tery cells through conduction and dissipating this

Optimising graphite composites and plate heat exchangers

Jun 1, 2020 · Thermal energy storage (TES) offers a cost-effective alternative to expensive battery-based systems which can be used to alleviate these issues [2], [3], [4]. The use of

Graphene for Thermal Storage Applications:

Jul 12, 2021 · A typical problem faced by large energy storage and heat exchange system industries is the dissipation of thermal energy. Management of thermal energy is difficult

Understanding Battery Thermal Conductive Pads: The Role of

Aug 6, 2025 · Explore the importance of battery thermal management in optimizing performance, safety, and longevity of modern batteries. This comprehensive guide covers the critical roles of

Heat dissipation performance research of battery modules

Mar 1, 2024 · Phase change materials are widely used in BTMS of power batteries, heat dissipation of electronic devices [7], [8], solar energy storage [9], [10], thermal insulation walls

Graphite vs. Lithium – A Complete Comparison

Nov 6, 2024 · Graphite has a low energy density but it effectively hosts lithium ions facilitating energy storage when used in Lithium-ion batteries. Graphite''s

Effects of thermal insulation layer material on thermal

Jan 15, 2024 · The safety accidents of lithium-ion battery system characterized by thermal runaway restrict the popularity of distributed energy storage lithium battery pack. An efficient

Performance enhancement of graphite-based flexible

Mar 15, 2025 · The air cooling is accompanied by insufficient heat transfer the heat generating a large radial temperature gradient on the surface of devices. The liquid cooling system has the

Analysis of Influencing Factors of Battery Cabinet Heat Dissipation

Safety is the lifeline of the development of electrochemical energy storage system. Since a large number of batteries are stored in the energy storage battery cabinet, the research on their heat

Graphite Heat Spreaders for EV Battery Thermal Dissipation

Jul 4, 2025 · Graphite heat spreaders in battery systems must manage thermal gradients that can exceed 20°C across cell surfaces during rapid charge-discharge cycles. In high-capacity

Numerical study on heat dissipation performance of a

Aug 30, 2023 · The simulation model is validated by the experimental data of a single adiabatic bare battery in the literature, and the current battery thermal management system based on

Synergistic performance enhancement of lead-acid battery

Nov 1, 2024 · The proposed PCM sheets with preferable thermal properties demonstrate potential to promote performance of lead-acid battery packs and such components are also expected to

Optimizing Graphite Plate Design for Efficient Heat

Jul 20, 2025 · Choosing high-quality graphite plates with the right thickness and purity helps spread heat evenly during battery annealing, improving battery life and performance.

6 FAQs about [Energy storage battery graphite sheet heat dissipation]

How effective is graphite in preserving battery temperature during high C-rate charging?

The results reveal that, among the examined materials, graphite is the most effective in maintaining the battery temperature within an acceptable range, particularly during high C-rate charging. Graphite integration significantly reduces the thermal stabilization time from over an hour to approximately 600 s.

Is graphite a good battery pack?

For higher-performance battery packs, the amount of aluminum needed for safe, efficient operation may result in a pack that is too heavy and bulky. Aluminum is dense and has poor thermal conductivity (200W/mK), but graphite is lightweight and has high thermal conductivity (400W/mK to 1,100W/mK).

Can hyperbolic graphene prevent the rapid heat accumulation of Li-ion battery cells?

Here we present an efficient thermal management system with high power and energy density by hyperbolic graphene phase change material, preventing the rapid heat accumulation of Li-ion battery cells.

Can graphite composites be used in thermal energy storage?

Recently a comprehensive review was conducted on the use of graphite composites in thermal energy storage . The analysis included numerous carbon materials such as graphite (G), graphite foams (GF), graphite fibres (GF), expanded graphite (EG), graphite nanoplatelets (GNP), graphene (GRF) and carbon nanotubes (CNT).

Does graphite regulate battery temperature?

The battery temperature exceeds the permissible range significantly when charging for 3C and 5C batteries. On the other hand, if graphite fills the gap between the batteries, the battery temperature remains below 318 K, demonstrating graphite’s effectiveness in regulating the battery pack temperature when charging at a rate of 5C.

Why is graphite a high thermal conductor?

In the graphite configuration, the high thermal conductivity of the graphite plate allows for rapid heat spreading, resulting in an initial peak as the system quickly redistributes heat before stabilizing.

Update Information

- New energy battery cabinet heat dissipation structure

- There are several ways to dissipate heat in energy storage battery cabinets

- Energy storage battery foam sheet manufacturer

- Male energy storage battery sales manufacturer

- Ghana energy storage battery model

- Montevideo outdoor energy storage battery manufacturer

- Czech Brno lithium iron phosphate energy storage battery

- Which energy storage battery is better in Djibouti

- Battery energy storage charging and power generation

- Pretoria s new generation battery energy storage system

- Low cost energy storage battery

- Majuro Energy Storage Lead Acid Battery Supply

- Lithium battery energy storage container transportation

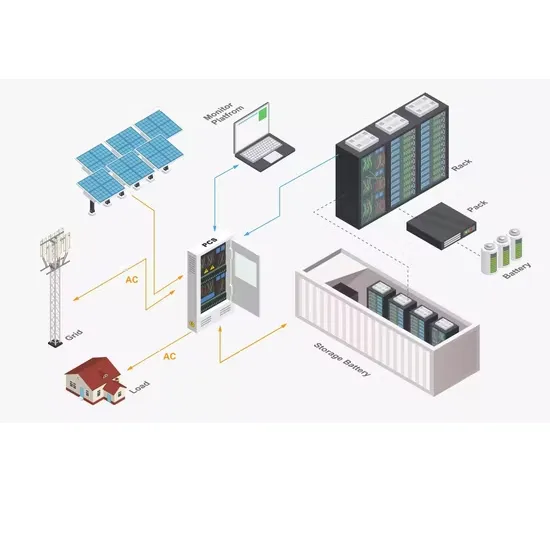

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.