Safety Risks and Risk Mitigation

Nov 1, 2024 · Challenges for any large energy storage system installation, use and maintenance include training in the area of battery fire safety which includes the need to understand basic

Lithium battery energy storage ranking

Now in its fourth edition, the Global Lithium-Ion Battery Supply Chain Ranking considers 46 individual metrics to track the supply chain potential across five equally weighted categories:

Battery Energy Storage Systems: Main Considerations for

5 days ago · This webpage includes information from first responder and industry guidance as well as background information on battery energy storage systems (challenges & fires), BESS

Safety Risks and Risk Mitigation

Nov 1, 2024 · Long-duration storage: Iron-air batteries can store energy for days (up to 100 hours), which is ideal for balancing renewable energy sources like wind and solar. Safe: Iron

Five Key Safety Precautions for Handling Lithium-Ion Batteries

Mar 4, 2025 · Lithium-ion batteries are widely used in various applications, from smartphones to electric vehicles, due to their energy efficiency and compact size. However, with their growing

Methods and precautions for lithium battery

Jan 29, 2024 · Li-ion battery is a high energy density battery which is widely used in mobile electronic devices, electric vehicles and energy storage systems,

LITHIUM BATTERY ASSEMBLY METHOD AND PRECAUTIONS

FAQS about Liquid-cooled energy storage lithium battery assembly and calculation Can a liquid cooling structure effectively manage the heat generated by a battery? Discussion: The

BATTERY HANDLING, MAINTENANCE & TEST

Apr 7, 2022 · The forward-looking innovation behind Crown Battery Flooded Lead Acid (FLA) and AGM Energy Storage batteries makes them ideal for renewable energy (RE) systems,

In-Depth Overview of Battery Cell Assembly Processes

Aug 17, 2025 · Thorough knowledge of battery cell assembly is imperative for driving innovations in storage technology and addressing emerging energy demands. Prologue to Battery Cell

Lithium Batteries: Safe Assembly & Usage Best Practices

To ensure the safe use of lithium batteries, observe these precautions: Prevent Overcharge and Discharge: Avoid excessive charging and discharging as they can degrade or damage battery

Key Considerations in the Lithium Battery Assembly Process

Feb 5, 2025 · Safety is the top priority when working with lithium batteries. Without proper precautions, workers face risks such as chemical exposure, short circuits, and thermal runaway.

EV Battery Manufacturing Safety: 5 Insights & Best Practices

Dec 2, 2024 · EV Battery Manufacturing Safety: Top Five Insights and Best Practices Here''s what you should know to safely operate and maintain compliance for an electric vehicle battery

What Are the Precautions for Lithium Battery Assembly?

Aug 2, 2025 · Lithium batteries are a common type of rechargeable battery used in various applications, from consumer electronics to electric vehicles. Proper assembly is crucial for

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · This final stage in the lithium-ion battery manufacturing process integrates individual cells into fully functional battery modules, complete with

Assembly process and installation precautions of lithium battery

May 17, 2022 · 1. Lithium-ion battery pack assembly processTools/raw materials: positive electrode material, negative electrode material, separator papersteps/methods①Pulping:The

BATTERY ENERGY STORAGE SYSTEMS (BESS)

Apr 28, 2025 · Aside from presenting a viable opportunity for energy storage or balancing electrical grids, BESS present significant fire and explosion risks, due to employment of

What Are the Precautions for Installing Lithium Iron Phosphate Battery

6 days ago · What Are the Precautions for Installing Lithium Iron Phosphate Battery Packs? Lithium iron phosphate (LFP) battery packs are a popular choice for energy storage systems

Layout precautions and manufacturing difficulties of energy storage

May 6, 2024 · Designing a printed circuit board (PCB) for energy storage systems requires careful consideration and planning to ensure optimal performance and reliability.

LITHIUM BATTERY ASSEMBLY METHOD AND PRECAUTIONS

What happens if a battery pack is cycled? When cycled, all batteries show large capacity losses over 18 cycles, but the greatest decrease occurs with the pack exhibiting 12 percent capacity

METHODS AND PRECAUTIONS FOR LITHIUM BATTERY ASSEMBLY

Add. . OSM 48v battery bank makes residential battery storage to a new level. OSM 5 kWh Lithium-Iron Phosphate Battery (LiFePO4), combining superior lithium-iron phosphate

Lithium Ion Battery

Oct 16, 2019 · Proper lithium-ion batteries storage is critical for maintaining an optimum battery performance and reducing the risk of fire and/or explosion. Many recent accidents regarding

DIY Battery Pack Safety: Complete Guide for 18650 and

Comprehensive safety guide for building DIY battery packs with 18650 and 21700 cells. Learn essential precautions, best practices, and expert tips for safe assembly and use.

Lithium Battery Assembly Method and Precautions

Apr 11, 2024 · When Assembling Lithium Batteries, Special Attention Should Be Paid to Raw Material Selection, Process Control, Safety Protection, Environmental Awareness and Other

Lithium battery assembly methods and precautions

As an important energy storage device, the assembly quality of lithium batteries directly affects battery performance and safety. This article will introduce the assembly methods and

5 FAQs about [Energy storage battery assembly precautions]

What are the safety precautions for storage batteries?

The general safety precautions for handling and storing alkaline batteries are the same as for lead-acid batteries with the following exceptions: The electrolyte in these batteries is alkaline but is similarly corrosive. This should be cleaned off with diluted ammonia water or soda solution, and affected areas then dried.

What precautions should be taken when charging a battery?

t circuit current. The following precautions should be observed when wo king on batteries:Remove watches, rings and o er metal objects.Use tools with nsulated handles.Wear rubbe gloves and boots.Do not lay tools or metal parts o top of batteries.Disconnect charging source prior to connecting or disconnecting

Can Li-ion battery chemistry be used for stationary grid energy storage?

Apart from Li-ion battery chemistry, there are several potential chemistries that can be used for stationary grid energy storage applications. A discussion on the chemistry and potential risks will be provided.

Are VRFB batteries toxic?

Toxicity: VRFBs are relatively toxic due to the oxides of vanadium. Weight: VRFBs are heavy due to the large electrolyte tanks and aqueous electrolyte (40 Wh/kg). Energy-to-volume ratio: VRFBs have a relatively poor energy-to-volume ratio (15-20 Wh/L). System complexity: VRFBs are more complex than standard storage batteries.

What are the disadvantages of a non lithium ion battery chemistry?

Oxygen reduction reaction: The oxygen reduction reaction (ORR) and oxygen evolution reaction (OER) kinetics are sluggish, which hinders commercialization. Air electrode corrosion: The air electrode can corrode. Few non-Lithium-ion battery chemistries are either in existence and several in research or small scale.

Update Information

- Outdoor energy storage battery assembly

- Norway energy storage lithium battery assembly plant

- New Zealand high voltage energy storage lithium battery assembly

- Liberia Energy Storage Lithium Battery Assembly Company

- Energy Storage Battery Cabinet Design Method

- Yerevan battery energy storage power station approved

- How much does a battery energy storage cabinet cost in Beijing

- 15kwh energy storage battery

- Portable energy storage battery source manufacturer

- Charging of liquid-cooled energy storage battery cabinet

- Energy storage lithium iron phosphate battery life

- North Korea portable energy storage battery enterprise

- Tbilisi energy storage battery recommended manufacturers

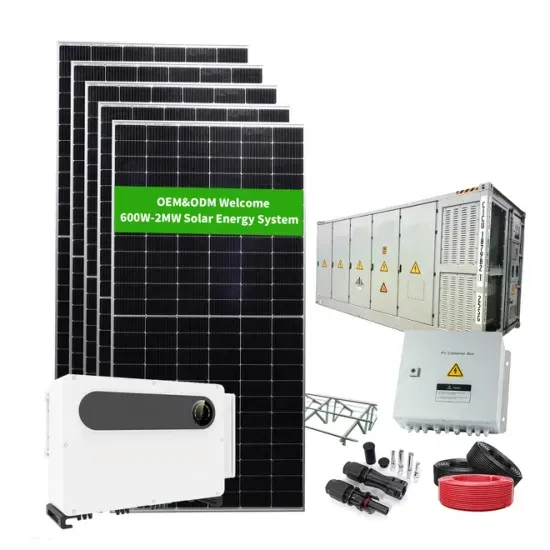

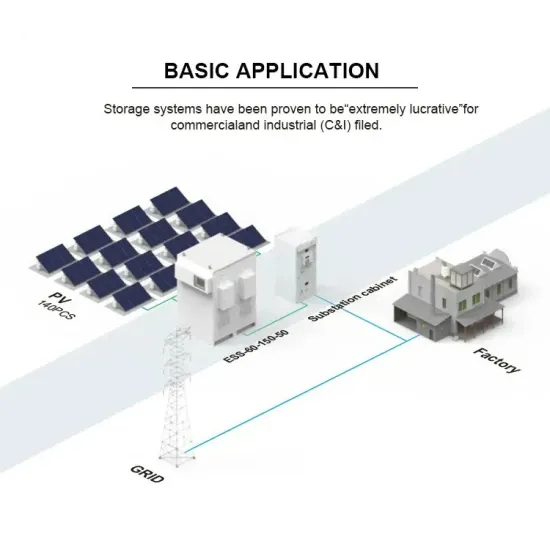

Solar Storage Container Market Growth

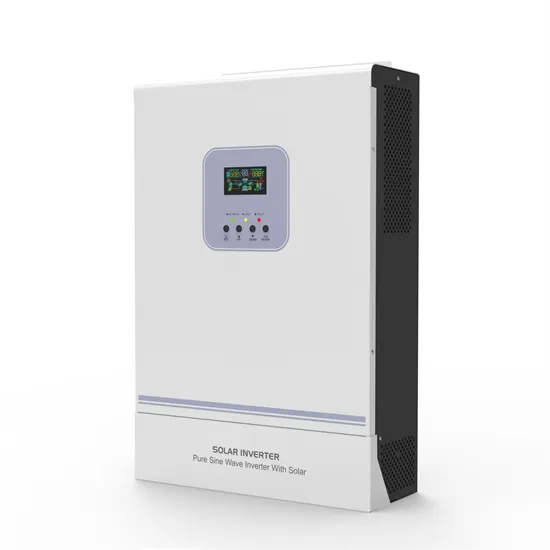

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

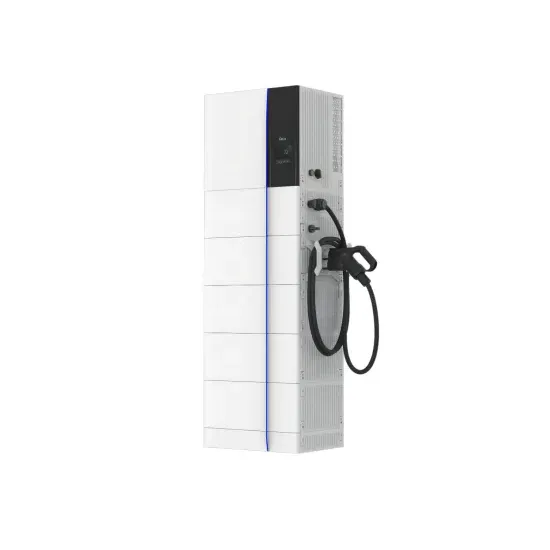

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.