Designing A Li-Ion Battery Charger and Load Sharing

Jul 15, 2008 · Depending on the product design or local government regulations, rechargeable batteries are often charged from inside the handheld devices or from battery charg-ing cradles.

Battery Charging Circuit Diagram and Practical Design Guide

Use a well-structured battery charging circuit diagram to ensure safe and reliable charging. A typical design includes a power source, current control, voltage regulation, and protection

Circuit control structure and battery cabinet for direct-current

A circuit control, pure electric technology, applied in the field of circuit control structure, battery cabinet and battery cabinet, can solve the problem of insufficient space for train electrical and

Simplify Voltage and Current Measurement in Battery

Dec 23, 2023 · Amplifier Usage in Battery Test Equipment In typical systems, a Buck converter is used as the power source for battery charging and a Boost converter is used for battery

Charging voltage control and current limit for battery chargers

The charger makes use of a pulse-width modulated control circuit utilizing a variable duty cycle to control charging current and couples a trim command signal responsive to a primary side

Battery Charging Circuits | Tutorials on Electronics | Next

Aug 15, 2025 · Lithium-ion batteries require sophisticated charging circuits, often employing techniques such as constant current/constant voltage (CC/CV) charging to ensure safety and

Understanding the Circuit Diagram of a Battery Management

In summary, the battery management system circuit diagram is a complex arrangement of voltage and current sensors, temperature sensors, control circuits, and switches that work together to

battery charger circuit – Electronics Projects Circuits

A superior design than the battery chargers sold in the market for 2..3k as 12V 1XX amp industrial chargers. Automatic battery charger is a versatile circuit for charging 12V lead acid batteries,

Battery Charger Circuit Diagram with Key Components

Detailed battery charger circuit diagram explaining component connections, functions, and layout for building a reliable charging system. Clear and practical guidance included.

4 Simple Li-Ion Battery Charger Circuits – Using

Jul 16, 2024 · In this post I have explained a four simple yet a safe way of charging a Li-ion battery using ordinary ICs like LM317 and NE555 which can

Energy storage high voltage cabinet pre-charging circuit

What is a pre-charge circuit? Applications and Benefits Pre-charge circuits are often used in electric vehicles (EVs) such as battery management systems, onboard chargers, and in

Managing Inrush Current (Rev. A)

Apr 1, 2023 · These problems can be mitigated by using Texas Instruments load switches. The load switches in the TPS229xx family are slew rate controlled to minimize inrush current. This

Intelligent Battery Charger Reference Design

May 24, 2006 · The PIC16C7XX controls battery charging and dis-charging through the Battery Charge Select and Bat-tery Discharge Select lines. Battery Temperature and Battery Voltage

A Li-Ion Battery Charger With Variable Charging Current and

Jun 14, 2021 · To preferably regulate the charging current and decrease circuit complexity for parallel charging, a battery charger with variable charging current (VCC) and au

Hybrid charging strategy with adaptive current control of

Nov 1, 2020 · Third, for the first constant current stage, the adaptive current profile is utilized based on the variable internal resistance of the battery, which can effectively reduce the ohmic

Simplest current limiting method for battery

Jan 3, 2022 · I need to charge 12V car battery (from main battery), but I have to limit current, because power cables are quite thin and I don''t want to draw too

Battery Charger Circuit Design with LM317 and Relay Control

Nov 17, 2024 · Learn how to build a simple and efficient battery charger circuit with LM317 and relay control. Perfect for charging 4-cell AA batteries with automatic shut-off

Improved_Charging_Methods_for_Lead-Acid_Batteries_Us

Apr 1, 2023 · The charger designs use current and voltage sensing combined with sequenced current and voltage control to maximize battery capacity and life for various applications. The

Battery current and voltage control system design with charging

Oct 10, 2014 · This paper presents the design of battery charging control system suitable for different battery types. A PI controller-based battery current control system is

6 FAQs about [Battery cabinet charging current control circuit]

What is a battery current control system?

The current control system is commanded by a superimposed battery voltage controller aimed at bringing the battery terminal voltage to the fully-charged state while also limiting the maximum battery charging current.

What is a charger IC?

Described are the design and operation of several charg-ing circuits using this IC. The charger designs use current and voltage sensing combined with sequenced current and voltage control to maximize battery capacity and life for various applications.

How do battery charger designs improve battery perfor-Mance?

The charger designs use current and voltage sensing combined with sequenced current and voltage control to maximize battery capacity and life for various applications. The presented material provides insight into expected improvements in battery perfor-mance with respect to these specific charging methods.

Are battery charging control systems suitable for different battery types?

Conferences > 2014 IEEE Conference on Contr This paper presents the design of battery charging control system suitable for different battery types. A PI controller-based battery current control system is designed with the aim of achieving robust control system behavior over a wide range of battery internal resistance variations.

How complex is a battery charging system?

The complexity (and cost) of the charging system is primarily dependent on the type of battery and the recharge time. This chapter will present charging methods, end-of-charge-detection techniques, and charger circuits for use with Nickel-Cadmium (Ni-Cd), Nickel Metal-Hydride (Ni-MH), and Lithium-Ion (Li-Ion) batteries.

What are CCCV charging techniques?

There is a wide range of CCCV charging techniques presented in the literature, such as switching between battery current and voltage control modes depending on the battery terminal voltage conditions and utilization of the so-called cascade control approach with or without adaptations with respect to the battery operating point .

Update Information

- What is the maximum charging current of the battery cabinet

- How to control the current of battery cabinet

- How much is the preheating current of the battery cabinet

- How much current does the energy storage cabinet battery output

- New energy battery cabinet self-service charging

- How to connect the lithium battery station cabinet control system

- Battery Cabinet and Charging Communication

- Slovenia energy storage cabinet battery charging

- The method of testing the current of the battery cabinet is

- Is the battery cabinet considered a power distribution control device

- Banjul outdoor communication battery cabinet charging

- The battery current of the energy storage cabinet is too strong

- Energy storage cabinet site charging battery

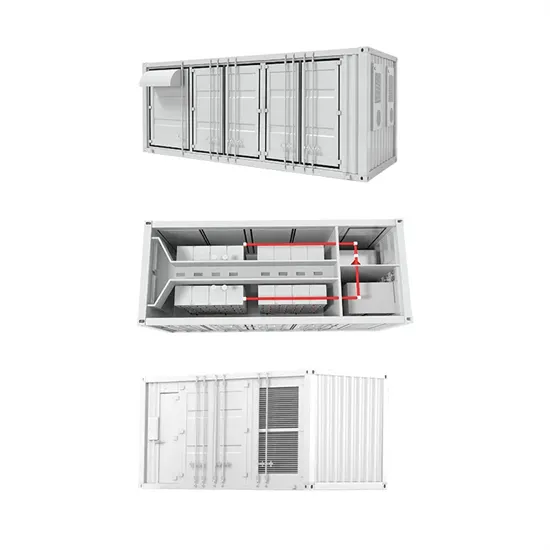

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

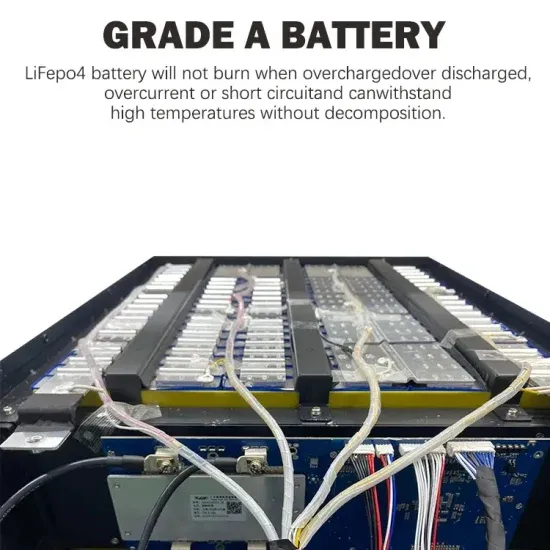

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.