What is the battery temperature in the energy storage box

In short, battery storage plants, or battery energy storage systems (BESS), are a way to stockpile energy from renewable sources and release it when needed. "If there''''s any

The best storage temperature and humidity for lithium batteries

Aug 19, 2025 · Storing lithium batteries at 15–25°C and 30–50% RH isn''t just about following specs—it''s about protecting your investment. Whether you''re a consumer storing power tools

A thermal management system for an energy storage battery

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper

Thermal Analysis and Optimization of Energy Storage Battery Box

Sep 1, 2023 · The performance, energy storage capacity, safety and lifetime of lithium-ion battery cells of different chemistries are very sensitive to operating and environmental temperatures.

Temperature effect and thermal impact in lithium-ion batteries

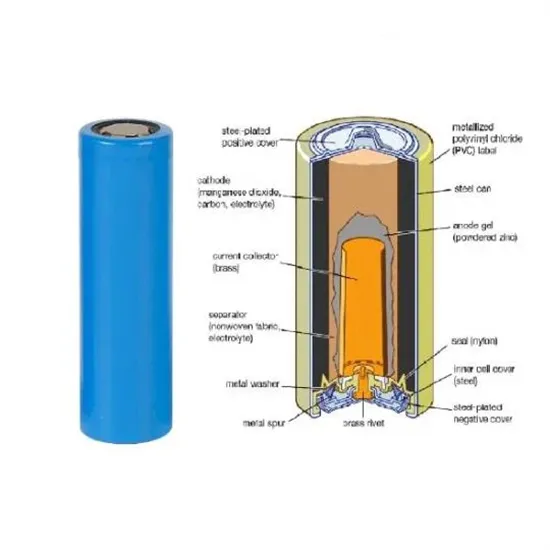

Dec 1, 2018 · Lithium-ion batteries, with high energy density (up to 705 Wh/L) and power density (up to 10,000 W/L), exhibit high capacity and great working performance. As rechargeable

The state of the art on preheating lithium-ion batteries in cold weather

In 2018, the global production of lithium-ion batteries was increased by around 20% from the 2017 level, reaching 188.80 GWh. Despite the advantages, the performance of lithium-ion batteries

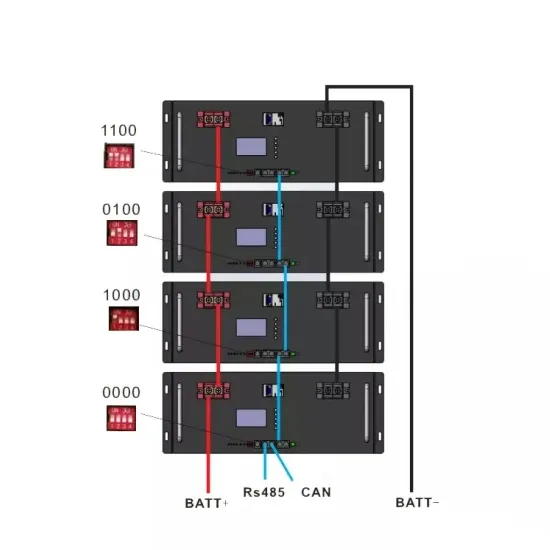

Residential Energy Storage Battery System User Manual

Mar 4, 2020 · ZNTECH LBB051100A energy storage power system products, which use lithium iron phosphate batteries is a high-power, pollution-free, maintenance-free green battery with

NTC Thermistors in Energy Storage Systems: Optimizing Battery

Feb 7, 2025 · Discover how NTC thermistors enhance battery pack temperature monitoring in energy storage systems. Learn about their inverse temperature-resistance relationship, fast

Temperature Sensitivity in Energy Storage and Battery

May 16, 2025 · Temperature sensitivity in energy storage and battery installation planning is crucial for optimal performance. Understanding how temperature affects battery efficiency

How Does Temperature Affect Battery Performance in Energy Storage?

Jun 26, 2025 · Temperature is a crucial factor affecting battery performance in energy storage systems. Understanding its impact on chemical reactions and implementing effective

Thermal Analysis and Optimization of Energy Storage Battery Box

Sep 1, 2023 · Based on a 50 MW/100 MW energy storage power station, this paper carries out thermal simulation analysis and research on the problems of aggravated cell inconsistency

Thermal effects of solid-state batteries at different temperature

Apr 1, 2024 · Solid-state batteries, which show the merits of high energy density, large-scale manufacturability and improved safety, are recognized as the leading candidates for the next

Monitoring and control of internal temperature in power batteries

Feb 1, 2025 · The thermal characteristics and temperature sensitivity of batteries are introduced first, followed by a detailed discussion of various internal temperature monitoring technologies,

In-situ temperature monitoring of a lithium-ion battery

Oct 1, 2022 · Uncertainty in the measurement of key battery internal states, such as temperature, impacts our understanding of battery performance, degradation and safety and underpins

Temperature state prediction for lithium-ion batteries based

Dec 1, 2023 · Due to the characteristic of high energy density and inexpensive price, lithium-ion batteries have been widely used in multi-scale energy storage devices [1]. The states,

The Ultimate Guide to Energy Storage Temperature Control Box

Mar 6, 2022 · If you''re managing solar farms, EV charging stations, or even just a home battery system, you''ve probably faced this headache: batteries that underperform in extreme heat or

Energy Storage Cabinet Temperature: The Critical Frontier in Battery

Jul 13, 2025 · When energy storage cabinet temperature fluctuates beyond 5°C tolerance bands, battery degradation accelerates by 32% – but how many operators truly monitor this invisible

Temperature prediction of lithium‐ion batteries

Mar 29, 2022 · Among them, the temperature prediction of LIBs is the key to prevent the occurrence of fire. At present, using surface temperature sensor to

Integrated cooling system with multiple operating modes for temperature

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Testing Energy Storage High-Voltage Boxes for Safety

Explore essential testing procedures for energy storage high-voltage boxes—from visual checks and CAN communication to insulation and temperature rise testing for safe battery systems.

6 FAQs about [Battery temperature in the energy storage box]

Why is internal temperature measurement important in power batteries?

Challenges of internal temperature measurement in power batteries The internal temperature measurement of power batteries is essential for optimizing performance and ensuring operational safety, particularly in high-demand applications such as electric vehicles and large-scale energy storage systems.

What are battery thermal characteristics and temperature sensitivity?

Battery thermal characteristics and temperature sensitivity are outlined, emphasizing their performance impacts. Internal temperature monitoring technologies are highlighted for their role in accurate, real-time data acquisition. Internal temperature management strategies are introduced to optimize performance.

How can NTC thermistors improve battery pack temperature monitoring?

As energy storage technologies continue to evolve, NTC thermistors remain a cornerstone for temperature measurement, offering the responsiveness and accuracy required to meet modern demands for dependable, sustainable, and scalable energy solutions. Discover how NTC thermistors enhance battery pack temperature monitoring in energy storage systems.

Can stacked power batteries measure temperature?

This technique pioneered the direct measurement of temperatures at multiple locations inside large, stacked power batteries. Experimental results indicated that even for batteries as thin as 7 mm, the internal temperature could differ from the surface temperature by >1.1 °C.

Do power batteries need temperature monitoring?

Currently, most of the temperature monitoring and thermal management of power batteries are carried out on the outer surface of the battery, lacking a comprehensive review of internal temperature monitoring and control of power batteries.

How does battery temperature management work?

Traditional battery temperature management has primarily relied on external control technologies such as air cooling, liquid cooling systems, and external low-temperature heating systems [172, 173]. These methods regulate temperature through thermal exchange between the battery casing and the environment.

Update Information

- Ghana Energy Storage Low Temperature Lithium Battery Factory

- Malabo New Energy Battery Storage Box

- Energy storage battery low temperature

- Huawei energy storage battery outer box

- Monaco battery energy storage box direct sales company

- Energy storage battery charging temperature

- Huawei Mexico Energy Storage Battery Box

- Guinea energy storage low temperature lithium battery

- Kyrgyzstan energy storage low temperature lithium battery

- Energy storage cabinet battery box

- Djibouti Energy Storage Low Temperature Lithium Battery Factory

- Energy storage battery box specifications and dimensions

- Sucre Energy Storage Battery Box

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.