Lithium-ion battery pack thermal management under high

Mar 1, 2024 · To promote the clean energy utilization, electric vehicles powered by battery have been rapidly developed [1]. Lithium-ion battery has become the most widely utilized dynamic

How Resistance, Temperature, and Charging Behaviors

Dec 18, 2023 · This article will introduce battery SOC and SOH and discuss three factors that can impact SOC and SOH: internal resistance, temperature, and charge/discharge behavior. It will

Challenges and opportunities toward fast-charging of lithium-ion batteries

Dec 1, 2020 · Therefore, the optimal charging algorithm of Li-ion batteries should achieve the shortest charging interval with minimal degradation. This paper thoroughly reviews the recent

Temperature Considerations for Charging Li-Ion

Apr 17, 2019 · The position of the phone on the inductive charging base was investigated to establish whether this could affect the resulting temperature of

Thermal Regulation Techniques for EV Batteries

Jul 30, 2025 · Fast charging of electric vehicle batteries generates substantial heat—up to 2.5 kW of thermal energy for a 150 kW charging session. Without

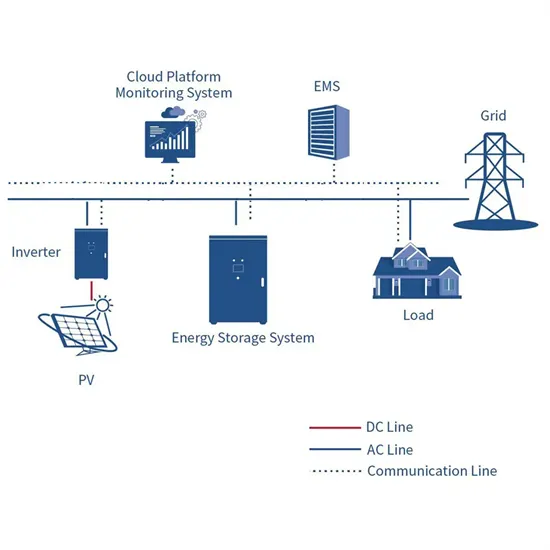

Thermal Management in Battery Energy Storage

Aug 14, 2024 · Operating outside the optimal temperature range (generally 20-40°C) can significantly reduce efficiency. At low temperatures, the internal

Lithium Battery Temperature Ranges: Operation

Aug 13, 2025 · Optimal Lithium Battery Temperature Range for Performance and Safety Lithium-ion batteries operate best between 15°C to 35°C (59°F to 95°F)

Lithium Battery Temperature Range: All the information you

Jan 17, 2025 · The ambient temperature directly affects the internal temperature of lithium-ion batteries. It is crucial to understand how the lithium battery temperature range affects the

What are the optimal ambient temperature ranges for EV charging

Dec 26, 2024 · The optimal ambient temperature range for EV charging typically falls between 0°C to 30°C (32°F to 86°F) according to general recommendations, though battery-specific

Battery technologies for grid-scale energy storage

Jun 20, 2025 · In this Review, we describe BESTs being developed for grid-scale energy storage, including high-energy, aqueous, redox flow, high-temperature and gas batteries.

Thermal effects of solid-state batteries at different temperature

Apr 1, 2024 · Solid-state batteries, which show the merits of high energy density, large-scale manufacturability and improved safety, are recognized as the leading candidates for the next

BU-410: Charging at High and Low Temperatures

Mar 1, 2022 · Batteries can be discharged over a large temperature range, but the charge temperature is limited. For best results, charge between 10°C and 30°C (50°F and 86°F).

How Do Temperature Ranges Affect Charging and

Sep 6, 2024 · Temperature plays a critical role in the performance, capacity, and longevity of batteries. Understanding how temperature affects both the charging and discharging

Sodium acetate-based thermochemical energy storage with low charging

May 10, 2024 · The electrification of heat necessitates the development of innovative domestic heat batteries to effectively balance energy demand with renewable power supply.

Design and Analysis of a Battery Thermal Management

Jul 2, 2025 · Fast charging of lithium-ion batteries presents significant thermal management challenges, due to the high demanding conditions of high C-rates, particularly at extreme

Temperature effect and thermal impact in lithium-ion batteries

Dec 1, 2018 · Accurate measurement of temperature inside lithium-ion batteries and understanding the temperature effects are important for the proper battery management. In

How much temperature can I use solar energy to charge my battery

Aug 15, 2024 · Charging batteries using solar energy typically thrives within a specific temperature band, emphasizing that most systems operate best around 25°C. Beyond this range, various

Energy storage management in electric vehicles

Feb 4, 2025 · Energy storage management strategies, such as lifetime prognostics and fault detection, can reduce EV charging times while enhancing battery safety.

Using Lithium Batteries in Cold Weather

Jun 29, 2023 · Wide temperature variations Battery charging voltage also changes with temperature. It will vary from about 2.74volts per cell at -40°C to 2.3 volts per cell at 50°C. This

All-temperature area battery application mechanism,

Jul 10, 2023 · Further applications of electric vehicles (EVs) and energy storage stations are limited because of the thermal sensitivity, volatility, and poor durability of lithium-ion batteries

6 FAQs about [Energy storage battery charging temperature]

What temperature should a battery be charged?

Batteries can be discharged over a large temperature range, but the charge temperature is limited. For best results, charge between 10°C and 30°C (50°F and 86°F). Lower the charge current when cold. Nickel Based: Fast charging of most batteries is limited to 5°C to 45°C (41°F to 113°F).

What temperature should a lithium battery be stored?

Proper storage of lithium batteries is crucial for preserving their performance and extending their lifespan. When not in use, experts recommend storing lithium batteries within a temperature range of -20°C to 25°C (-4°F to 77°F). Storing batteries within this range helps maintain their capacity and minimizes self-discharge rates.

What temperature should a lithium ion battery be charged at?

Lithium-ion battery performance during charging depends heavily on maintaining optimal temperature ranges, typically between 15-35°C.

What happens if you charge a lithium battery at high temperatures?

Charging lithium batteries at extreme temperatures can harm their health and performance. At low temperatures, charging efficiency decreases, leading to slower charging times and reduced capacity. High temperatures during charging can cause the battery to overheat, leading to thermal runaway and safety hazards.

How hot do electric vehicle batteries get?

Fast charging of electric vehicle batteries generates substantial heat—up to 2.5 kW of thermal energy for a 150 kW charging session. Without adequate thermal management, battery temperatures can rise above 45°C, accelerating degradation and forcing charging systems to throttle power delivery to prevent damage.

How does temperature affect lithium ion batteries?

As rechargeable batteries, lithium-ion batteries serve as power sources in various application systems. Temperature, as a critical factor, significantly impacts on the performance of lithium-ion batteries and also limits the application of lithium-ion batteries. Moreover, different temperature conditions result in different adverse effects.

Update Information

- Outdoor safe charging energy storage battery cabinet price

- Hyx8 photovoltaic energy storage cabinet battery charging

- Djibouti Energy Storage Low Temperature Lithium Battery Factory

- Dakka energy storage low temperature lithium battery

- Energy storage cabinet site charging battery set

- St Johns energy storage low temperature lithium battery

- Energy storage cabinet battery charging time

- Charging of liquid-cooled energy storage battery cabinet

- Energy storage charging pile battery replacement

- Energy storage battery low temperature

- Energy storage battery charging module

- Muscat energy storage low temperature lithium battery

- Energy storage cabinet site charging battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.