Inverter Power Factor Modes: How do they afect voltage

Nov 23, 2020 · Inverter Power Factor Modes: How do they afect voltage rise calculations? As Australia continues to see the trend to increase system capacity to medium or large scale Grid

CMOS Inverter: DC Analysis

Feb 9, 2006 · in an inverter, I Dn = I Dp, always! Decreasing L (reducing feature size) is best way to improve speed! How do you improve speed within a specific gate? frequency, and strongly

Why Voltage Matters

Jun 12, 2025 · At their core, inverters convert direct-current (DC) voltage into alternating-current (AC) voltage and back again, enabling the use of stored or generated energy in a wide range

Inverter Power Factor Modes: How do they afect voltage

Nov 23, 2020 · Inverter Power Factor Modes: How do they afect voltage rise calculations? em, it becomes valuable for Inverter Energy Systems (IES) to have ways to support the power

Why DC supply voltage is increasing when

Mar 31, 2024 · 0 If I connect my inverter to a resistive load or small inductive load the DC supply voltage (in my application it is 56 V) stays constant. However, if

Comparative Characteristics of Autonomous Voltage Inverters

Dec 8, 2024 · Abstract The article shows the relevance of developing and studying three-level autonomous voltage inverters (AVIs) for three-phase industrial uninterruptible power supplies

Difference Between Inverter and Converter –

May 22, 2025 · Inverters: Commonly used in renewable energy systems (such as solar power), uninterruptible power supplies, and electric vehicles. Converters:

Why in a inverter DC to AC 12V et 220V when I increase the voltage

Jun 20, 2024 · A transformer or DC->AC inverter passes Power, not just Voltage or just Current. Power is Voltage times Current, so if the transformer or inverter increases the voltage, it must

Running Inverters in Parallel: A Comprehensive

Jul 14, 2023 · This setup ensures efficient and uninterrupted electricity supply, offering flexibility and scalability for growing power requirements. Running

Understanding inverter frequency – effects and

Oct 1, 2024 · In today''s world, inverters play a vital role in various applications, such as home solar power system, inverter for office use, inverter for van, etc.

Understanding inverter voltage

Jan 10, 2024 · Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and

The method of reducing the CMOS inverter switching

Dec 12, 2023 · However, with the exist-ing tendency to decrease the supply voltage, the contribution of short-circuit power losses to the total power consumption increases. Short

Converting DC to AC: Basic Principles of Inverters

May 28, 2024 · This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC

6 FAQs about [Inverter increases power supply voltage]

How does an inverter work?

The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed voltage, and the pulses are smoothed by the motor coil so that a sine wave current flows to the motor to control the speed and torque of the motor.

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What is the difference between an inverter and a converter?

An inverter is an electrical device, which converts DC power to AC power and either increases or decreases the voltage level accordingly. In comparison, a converter changes the voltage level but does not change its type. So in converters, an AC voltage would still be AC and a DC voltage would still be in DC.

Are inverters AC or DC?

So in converters, an AC voltage would still be AC and a DC voltage would still be in DC. Inverters are becoming more popular along with along with solar power systems where we get a low voltage DC supply to power ordinary appliances that either run on 110V or 220V AC. Inverters are used in a large number of electrical power applications.

Why is inverter voltage important?

In the realm of power electronics, the inverter voltage is a critical parameter that dictates its performance, compatibility, and safety. Understanding the intricacies of inverter voltage is essential for anyone seeking a reliable and efficient power supply.

Why do DC power sources use an inverter?

Therefore, DC power sources use an inverter to change DC to AC. Early inverters were rotary motor–generators, connected by a shaft, and they mechanically converted/inverted DC to AC. Modern inverters are electronic devices that use semiconductors to change DC to AC.

Update Information

- What is the auxiliary power supply voltage of the inverter

- High voltage power supply full bridge inverter price

- Portable inverter recommended power supply

- DC Constant Voltage Uninterruptible Power Supply

- What is the base station power supply voltage standard

- Solar panels as inverter power supply

- Wide voltage and high power inverter

- Communication base station inverter grid-connected signal tower power supply

- Outdoor power supply 12v connected to inverter

- Inverter Energy Storage Power Supply Price

- Inverter as outdoor power supply

- Communication base station wind-solar hybrid inverter power supply process

- 12v outdoor power supply with inverter

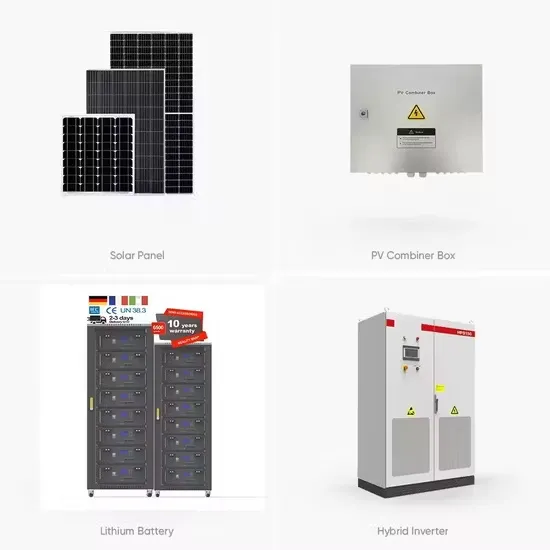

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.