How to calculate the current size of the battery cabinet

You can calculate the battery size for inverters using the formula B = P × t / V dc, where B is the battery capacity in ampere-hour, P is the inverter''''s power rating, t is the duration of power

How to Calculate Battery Voltage

Jun 17, 2025 · To calculate battery voltage, you measure the potential difference between the positive and negative terminals using a digital multimeter or voltmeter. It''s a quick, non

How to calculate the battery cabinet occupied by single

attery kWh, the first step is to determine the battery voltage. The voltage is typically specified by the battery manufacturer and can usuall be found on the battery label or in the product

Calculating Battery Current | Information by Electrical

Jun 21, 2014 · 271A on the nameplate on what piece of equipment? Seems odd for a cabinet with two 400A breakers. Your current will be controlled mostly by the load. Short circuit current of

Battery Voltage Calculator

Aug 15, 2024 · The Battery Voltage Calculator helps users calculate two critical voltage metrics: the battery voltage under load and the open circuit voltage. These calculations are vital for

Battery Capacity Calculator

Sep 5, 2022 · The battery capacity calculator is an excellent choice if you want to know what battery capacity is or if you need to compute the properties of various batteries and compare

Battery Voltage Calculator, Formula, Battery Volts Calculation

2 days ago · Enter the values of current, I b (A) and internal resistance, R b (Ω) to determine the value of battery voltage, V b (V). Battery Voltage is a fundamental parameter in electrical

How to calculate the battery cabinet current

To calculate battery kWh, the first step is to determine the battery voltage. The voltage is typically specified by the battery manufacturer and can usually be found on the battery label or in the

Onlin free battery calculator for any kind of battery

Free battery calculator! How to size your storage battery pack : calculation of Capacity, C-rating (or C-rate), ampere, and runtime for battery bank or storage system (lithium, Alkaline, LiPo, Li

How to calculate the internal resistance of the battery

How do you calculate internal resistance in a circuit? is the voltage drop,and I is the current flowing through the circuit. Divide the voltage drop by the kno n-value resistor to calculate the

How many volts is the energy storage battery cabinet?

Sep 10, 2024 · The specific voltage of a battery cabinet is determined by several factors, including the types of batteries used, the configuration of the storage system, and the overall energy

Arc-in-a-Box: DC Arc Flash Calculations Using a

Jan 10, 2023 · Abstract A method is proposed for calculating the incident energy and the arc flash boundary distance for dc systems when an arc is bounded inside a space such as a battery

Battery Voltage: Basics and Importance for Optimal

Jan 30, 2025 · Have you ever wondered what the voltage on a battery means, or why it''s such a critical factor in choosing the right one for your device or vehicle? Whether you''re picking a

Calculate Battery Life and Capacity

Battery Calculator This battery calculator helps you to estimate the runtime for a device based on the battery capacity, voltage, device power consumption, and system efficiency. How to Use:

Battery Voltage Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · To calculate the battery voltage ( (V_b)), use the formula: [ V_b = I_b times R_b ] where: (R_b) is the battery resistance (ohms). For instance, if a battery has a current of 2

How to calculate the internal resistance of the battery

How do you calculate internal resistance in a circuit? Use Ohm''s law (R = V/I) to calculate the internal resistance,where R is the internal resistance,V is the voltage drop,and I is the current

Battery Pack Calculator | Good Calculators

Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Battery Voltage Calculator

Aug 2, 2024 · Calculating battery voltage is crucial for several reasons. It helps in assessing the health and state of charge of a battery, determining if a battery can effectively power a device,

How to calculate the heat dissipated by a battery pack?

Aug 22, 2018 · I have a battery pack consisting of 720 cells. I want to calculate the heat generated by it. The current of the pack is 345Ah and the pack voltage is 44.4Volts. Each cell has a

How to calculate the power of the battery cabinet current

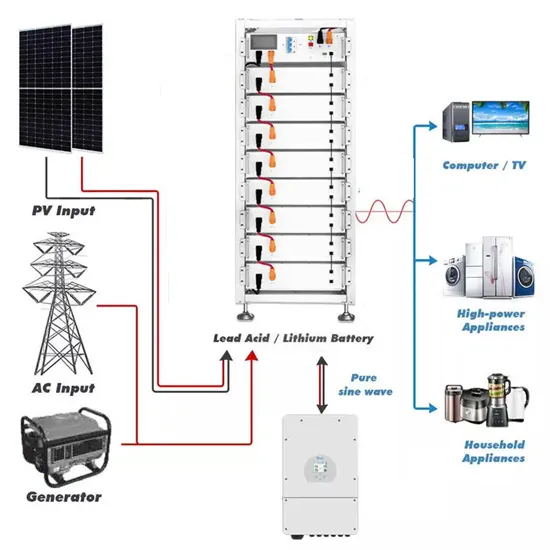

How do you calculate battery capacity? Multiplying the average or nominal battery voltage times the battery capacity in amp-hours gives you an estimate of how many watt-hours the battery

6 FAQs about [How to calculate the voltage of the battery cabinet]

What is a battery voltage calculator?

» Electrical » Battery Voltage Calculator The Battery Voltage Calculator helps users calculate two critical voltage metrics: the battery voltage under load and the open circuit voltage. These calculations are vital for assessing battery health, performance, and suitability for specific applications.

How to calculate the voltage of a battery in a series?

Even if there is various technologies of batteries the principle of calculation of power, capacity, current and charge and disharge time (according to C-rate) is the same for any kind of battery like lithium, LiPo, Nimh or Lead accumulators. To get the voltage of batteries in series you have to sum the voltage of each cell in the serie.

How do you calculate current flowing through a battery?

Suppose a battery has an internal resistance of 0.3 ohms, and the battery voltage is 0.9V. Calculate the current flowing through the battery. Given: V b (V) = 0.9V, R b (Ω) = 0.3 Ω. Battery voltage, V b (V) = I b (A) * R b (Ω)

What is battery voltage?

Battery Voltage is a fundamental parameter in electrical engineering and electronics, indicating the potential difference across a battery’s terminals. It is essential for ensuring proper operation of electrical devices by providing the necessary power output.

How do you measure battery resistance?

Battery resistance can be measured using a multimeter or a specialized battery resistance tester. The measurement involves applying a known load to the battery and measuring the voltage drop, which allows the resistance to be calculated.

What is voltage per cell (V)?

Voltage per Cell (V): The nominal voltage of each individual cell, which varies depending on the battery chemistry (e.g., 1.2V for NiMH, 3.7V for Li-ion). Here’s a table of key terms related to battery voltage calculations that users commonly search for: The voltage of a fully charged battery with no load applied.

Update Information

- How to calculate the storage time of battery cabinet

- How to calculate the battery power of the energy storage cabinet

- How many mAh does the energy storage cabinet battery have

- How much is the integrated system of battery cabinet in Kazakhstan

- How much is the preheating current of the battery cabinet

- How to join the site energy battery cabinet

- Battery cabinet voltage shows 0V

- How to install the outdoor cabinet battery energy storage cabinet

- How much does a battery energy storage cabinet cost in Palau

- How to buy a new energy battery cabinet cost-effectively

- How big is the single battery in the new energy battery cabinet

- How is the energy battery cabinet at the Tbilisi site

- How much does it cost to install a battery cabinet in Swaziland

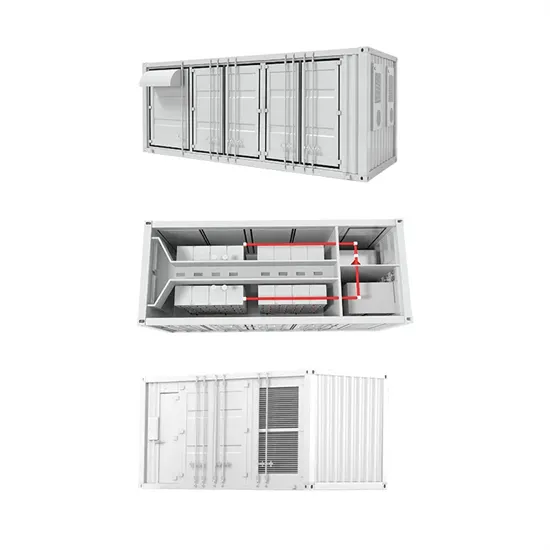

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

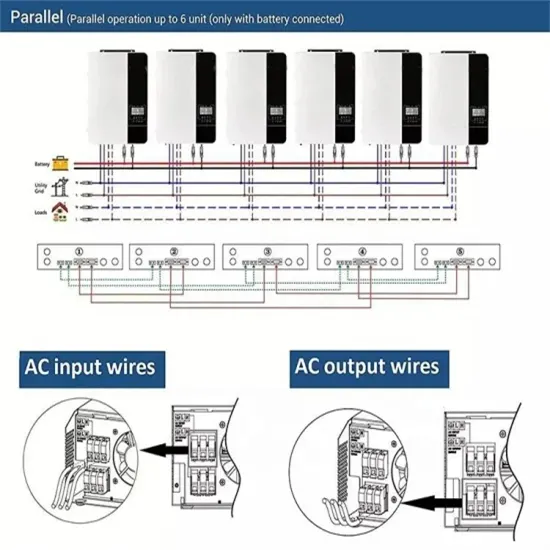

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.