How to select the dc bus voltage value for single

Jun 1, 2024 · For single-phase system, the maximum line-to-line voltage needs to be generated by the inverter is simply the grid''s line-to neutral voltage. So, for

Inverter Voltage Calculator, Formula, Inverter Voltage

3 days ago · Inverter Voltage Formula: Inverter voltage (VI) is an essential concept in electrical engineering, particularly in the design and operation of power electronics systems. It describes

What is inverter start up voltage | DIY Solar Power Forum

Apr 18, 2022 · I''m just trying experiment/learn solar. Anyway I''m hoping to up fit a larger inverter. Question is I''m hoping to fit a proper home inverter but the minimum ''startup'' voltage i see is

Introduction on technical guidelines for utilities

Oct 21, 2020 · The minimum number of modules in a string is determined by dividing the effective minimum operating voltage of the MPPT of the inverter (that is allowing safety margin) by the

Why is the starting voltage of the inverter higher than the minimum

In photovoltaic inverters, there is a rather strange parameter, that is, the inverter input starting voltage. This voltage is approximately 30V higher than the minimum operating voltage. For

Interpreting inverter datasheet and main parameters | AE 868

Each inverter has a minimum input voltage value that cannot trigger the inverter to operate if the PV voltage is lower than what is listed in the specification sheet. Why is start-up voltage

Crucial Start-Up Voltage for Solar Inverters

Sep 29, 2023 · The start-up voltage for a solar inverter is the minimum voltage required to initiate its operation. This voltage is crucial as it marks the point at

Array voltage sizing according to inverter

Aug 13, 2025 · The minimum array operating voltage (i.e. Vmpp at max. module operating temperature, 60°C by default) should be above the minimum inverter''s operating voltage

Photonik | String Voltage Calculator

Oct 13, 2023 · Solar String Voltage Calculator Why is calculating the string voltage so important? When designing a solar system using string solar inverters or solar charge controllers,

MoDel sPeCiFiCations oF inVerter

Jun 9, 2016 · The PCU / Inverters should comply with applicable IEC/ equivalent BIS standard for eficiency measurements and environmental tests as per standard codes IEC 61683/IS 61683

Project design > Grid-connected system definition > Array voltage

Nov 7, 2024 · The minimum array operating voltage (i.e. at max. module operating temperature, 60°C by default) should be above the minimum inverter''s operating voltage (Vmin of MPPT

difference between PV input and MPPT range

Aug 31, 2021 · MPPT Range is the voltage range (in this case 125V - 425V) over which your MPPT will operate effectively and be able to extract power from your array. PV Input Voltage

Understanding inverter voltage

Jan 10, 2024 · The start inverter voltage is the minimum input voltage required for the inverter to initiate the conversion process. In the case of a 12V inverter, the start inverter voltage is

Array voltage sizing according to inverter

Aug 13, 2025 · The voltage conditions are visualized on the upper graph of this tool: The string voltage has to match the following conditions: The minimum array operating voltage (i.e. Vmpp

Solar Inverter String Design Calculations

The following article will help you calculate the maximum / minimum number of modules per series string when designing your PV system. And the inverter sizing comprises two parts,

Technical White Paper SolarEdge Single Phase Inverter

Sep 11, 2020 · Inverters The SolarEdge inverters employ a very high efficiency single-stage conversion, transformer-less topology. The SolarEdge inverter includes an independent

How to String Sizing

Oct 20, 2024 · Once you find this voltage, find the minimum start-up or MPPT voltage for the inverter and calculate the minimum string length. (Inverter Min Voltage) / ( V low) = Minimum

Frequently Asked Questions about Inverters

Frequently Asked Questions about Inverters How much battery capacity do I need with an inverter? As a rule of thumb, the minimum required battery capacity for a 12-volt system is

6 FAQs about [Minimum inverter voltage]

What are the parameters of a PV inverter?

Aside from the operating voltage range, another main parameter is the start-up voltage. It is the lowest acceptable voltage that is needed for the inverter to kick on. Each inverter has a minimum input voltage value that cannot trigger the inverter to operate if the PV voltage is lower than what is listed in the specification sheet.

How many MPPT inputs does an inverter have?

Most inverters come with two MPPT inputs, allowing them to track two different arrays with different voltage profiles. Minimum startup voltage is the lowest voltage at which an inverter will begin operation. The minimum startup voltage 4 tells you the lowest point the inverter needs to begin functioning.

What is a start inverter voltage?

The start inverter voltage is the minimum input voltage required for the inverter to initiate the conversion process. In the case of a 12V inverter, the start inverter voltage is typically around 9.5VDC. This threshold ensures that the inverter can begin its operation reliably without placing undue stress on the connected battery.

How to choose the right inverter size?

Real-World Applications: Catering for Start-Up Voltage (Voltage during cranking) to Specific Systems Allocating the right size for inverters involves just picking the models with starting voltage which is largely in collaboration with the specifications of the PV array .

What is the maximum input voltage for a 12V inverter?

The maximum input voltage for an inverter is a critical specification that ensures the device operates within safe limits. For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and protect the inverter from potential damage.

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

Update Information

- 48v inverter maximum and minimum voltage

- The voltage is low after inverter rectification

- The voltage becomes higher when the inverter is heavily loaded

- Inverter output voltage is slow

- High voltage grid-connected inverter communication method

- 12v inverter voltage high

- Advantages of Voltage Source Inverter Regulation

- What is a voltage tracking PWM inverter

- How many volts does the inverter output voltage

- Can t the high voltage of the inverter be adjusted to a lower voltage

- High voltage inverter 28000

- Is dual voltage inverter good

- EK High Voltage Inverter

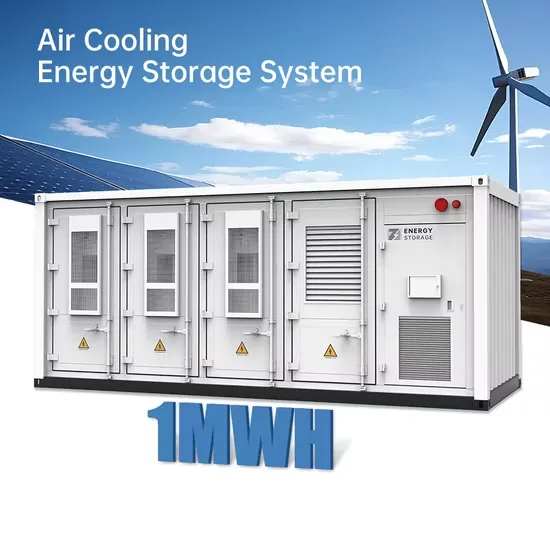

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.