Affordable Cadmium Telluride PV Factory – Quality Solar

May 13, 2025 · Premium Cadmium Telluride PV solutions from top manufacturers in China. Committed to quality and innovation, our products ensure exceptional performance and a

Environmental Life Cycle Assessment of Electricity from

Nov 19, 2021 · Environmental Life Cycle Assessment Life Cycle Assessment (LCA) is a structured, comprehensive method of quantifying material and energy flows, including the

Embodied energy and carbon from the manufacture of cadmium telluride

Jul 20, 2022 · The most prevalent technology, silicon (Si) PV, has greater than 90% of the global market share. 4 Cadmium telluride (CdTe) PV makes up ∼90% of the balance, with the vast

The industry chain of photovoltaic inverters

Dec 4, 2022 · The supply chain for solar PV has two branches in the United States: crystalline silicon (c-Si) PV, which made up 84% of the U.S. market in 2020, and cadmium telluride

What are Cadmium Telluride Solar Cells? (2024)

Mar 14, 2024 · Cadmium Telluride (CdTe) is a second-generation solar cell used in thin solar panel technology that maximizes the efficiency of converting solar

Cadmium Telluride Solar Cells | Photovoltaic Research | NREL

Apr 3, 2025 · Cadmium Telluride Solar Cells The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and

Quality Cadmium Telluride Photovoltaics from China

May 13, 2025 · Get high-quality Cadmium Telluride photovoltaics from reliable manufacturers in China. Connect with us for innovative clean technology solutions and dependable partnership

Key Points of Inverter Selection in BIPV Project

Dec 29, 2021 · The curtain wall BIPV field occupies the mainstream position. Thin film batteries mainly include copper indium gallium selenium (CIGS), cadmium

Life Cycle Inventories and Life Cycle Assessments of

Dec 16, 2020 · The IEA Photovoltaic Power Systems Programme (IEA PVPS) is one of the TCP''s within the IEA and was established in 1993. The mission of the programme is to "enhance the

A Detailed Guide to Cadmium Telluride Solar Cells

Jan 12, 2022 · The cadmium telluride photovoltaic solar cells are the next most ample solar cell photovoltaic technology after crystalline silicon-based solar

CADMIUM TELLURIDE ADVANTAGES AMP DISADVANTAGES

Cadmium telluride flexible photovoltaic panels Cadmium telluride (CdTe) photovoltaics is a (PV) technology based on the use of in a thin layer designed to absorb and convert sunlight into

Cadmium Telluride Solar Panels: An Introduction

Aug 25, 2023 · Cadmium telluride solar panels are thin-film photovoltaic devices that convert sunlight directly into electricity through the photovoltaic effect.

Embodied energy and carbon from the manufacture of cadmium telluride

Jul 20, 2022 · This work examines the embodied energy and embodied carbon (the amount of energy and greenhouse gas emissions required for manufacturing) of the two dominant types

Raw materials for photovoltaic inverter manufacturing

Apr 22, 2021 · The supply chain for solar PV has two branches in the United States: crystalline silicon (c-Si) PV, which made up 84% of the U.S. market in 2020, and cadmium telluride

Specifications and parameters of cadmium telluride

Download scientific diagram | Specifications and parameters of cadmium telluride translucent thin-film photovoltaic modules. from publication: Study on the Effect of Plant Growth on the Power

Brief review of cadmium telluride-based photovoltaic

Cadmium telluride (CdTe) is the most commercially successful thin-film photovoltaic technology. Development of CdTe as a solar cell material dates back to the early 1980s when ∼10%

Solar Cells: Energy Payback Times and Environmental Issues

Jul 15, 2020 · The PV technologies investigated were single- and multi-crystalline silicon modules and thin-film modules, such as amorphous silicon (a-Si), copper indium gallium diselenide

Cadmium telluride photovoltaics

Nov 11, 2019 · describes a photovoltaic (PV) technology that is based on the use of cadmium telluride, a thin semiconductor layer designed to absorb and convert sunlight into electricity.[1]

A real case of thin film PV alternatives to cSi based on a-Si

Feb 15, 2025 · The study consists of comparing common multicrystalline silicon photovoltaic generators, amorphous silicon photovoltaics and cadmium telluride photovoltaics. Each

6 FAQs about [Cadmium Telluride Photovoltaic Inverter]

What is cadmium telluride (CdTe) photovoltaic (PV)?

The United States is the leader in cadmium telluride (CdTe) photovoltaic (PV) manufacturing, and NREL has been at the forefront of research and development in this area. PV solar cells based on CdTe represent the largest segment of commercial thin-film module production worldwide.

What are cadmium telluride solar panels?

Cadmium telluride solar panels are thin-film photovoltaic devices that convert sunlight directly into electricity through the photovoltaic effect. Unlike traditional silicon solar panels, which use crystalline silicon wafers, CdTe panels employ a thin layer of cadmium telluride semiconductor material as the absorber layer.

What is cadmium telluride (CdTe)?

PDF | Cadmium telluride (CdTe) is the most commercially successful thin-film photovoltaic technology. Development of CdTe as a solar cell material dates | Find, read and cite all the research you need on ResearchGate

Are cadmium telluride modules a promising technology?

The case of cadmium telluride modules demonstrates a moderate degradation rate, being a technology that, due to its efficiency and with the improvement in characteristics in the latter years, would be one of the most promising technologies.

What are PV solar cells based on CdTe?

PV solar cells based on CdTe represent the largest segment of commercial thin-film module production worldwide. Recent improvements have matched the efficiency of multicrystalline silicon while maintaining cost leadership.

Does cadmium telluride improve efficiency?

In any case, other materials such as cadmium telluride have clearly improved in efficiency, going from 9 % to nearly 20 % in the last 10 years . In contrast, efficiency increase for hydrogenated amorphous silicon a-Si:H has been rather smaller, from 9.5 % in 2004 to 10.3 % in 2015 .

Update Information

- Cadmium telluride photovoltaic glass

- Phnom Penh non-standard photovoltaic curtain wall glass components cadmium telluride

- Kazakhstan Cadmium Telluride Photovoltaic Tile Purchase

- Cadmium ion photovoltaic glass

- Bidirectional photovoltaic energy storage inverter

- Photovoltaic panels parallel inverter

- Photovoltaic off-grid inverter self-operation

- Uzbekistan photovoltaic module inverter manufacturer

- Armenia photovoltaic energy storage inverter customization

- Solar photovoltaic inverter 12v to 220v

- Photovoltaic inverter pv overvoltage

- Photovoltaic lithium battery inverter conversion 220v

- Gw30k-dt photovoltaic inverter

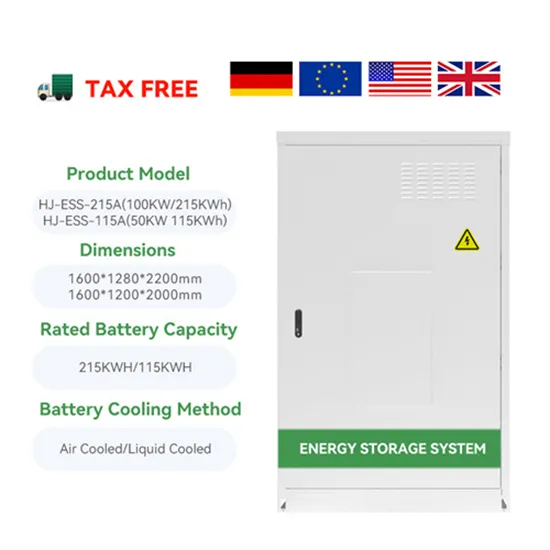

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.