The Application of SiC Devices in Photovoltaic Grid-connected Inverters

Oct 26, 2020 · The continuous development of photovoltaic grid-connected technology extended the requirement on higher power density and higher efficiency for power converters. In this

Silicon Carbide Semiconductors--The Next Key Technology

Jun 23, 2025 · Automotive Electronics Automotive Electronics> Automotive Sensors/MCU> Silicon Carbide Semiconductors--The Next Key Technology for Electric Vehicles and

Identifying the potential of SiC technology for PV inverters

Oct 6, 2023 · Silicon Carbide (SiC) devices offer energy efficiency improvements over conventional silicon (Si) semiconductors. Through measurements and simulation results, this

The Application of SiC Devices in Photovoltaic Grid-connected Inverters

Oct 26, 2020 · In this respect, the application of silicon carbide (SiC) high-power power electronic devices in photovoltaic inverter systems can simplify the system design, simplify the heat

Downsizing silicon carbide inverters – pv

Feb 17, 2020 · However, defects at the interface between the silicon carbide and the insulating silicon dioxide material still represent a big hurdle to bringing the

International Journal of Engineering Technology

Feb 27, 2025 · The increasing global demand for energy-efficient electronics, electric vehicles, and renewable energy systems has accelerated the adoption of WBG semiconductors [17].

Impact of silicon carbide semiconductor technology in Photovoltaic

Mar 1, 2016 · The increased awareness of the significance of solar energy has led to intensified research in the areas of solar energy harvesting. To increase the cost effectiveness of the

Silicon Carbide Thin Film Technologies: Recent Advances in

Oct 3, 2023 · In Part I of a two-part report, we provide a detailed and systematic review of the latest progress in cutting-edge innovations for the silicon carbide (SiC) material system,

Poly-SiC Characterization and Properties for SmartSiC

Introduction Silicon carbide (SiC) power devices are increasingly becoming pivotal components for high-power electronics, encompassing photovoltaic (PV) and traction inverters, power

IPG5 800V Silicon Carbide inverter for efficient electric

McLaren Applied''s new Silicon Carbide 800V inverter is the next step in electrification McLaren Applied''s new 800V Silicon Carbide Inverter is the ideal solution for automotive OEMs who

Development of a new photovoltaic inverter with silicon

corporating a new 1700V-rated silicon carbide (SiC) diode, tested for operation at full power of a 1500V inve. nt is a final report, focusing primarily on the newly established competenci.

silicon carbide inverters – pv magazine International

Feb 17, 2020 · Katek, a German PV inverter manufacturer, says its 4.6 kW coolcept fleX inverter features silicon carbide (SiC) semiconductors from US-based Navitas Semiconductor.

Paper Title (use style: paper title)

Aug 13, 2018 · Here the SiC-based multilevel inverters are analysed in detail. The simulated results are shown for both Si and SiC MOSFETs. The power loss analysis is performed on the

Extreme high efficiency enabled by silicon carbide (SiC)

Mar 15, 2024 · The GFL PV inverter is controlled as a current source and follows the power grid frequency in generating AC power. They do not react to the grid''s frequency change or power

Effects of silicon carbide MOSFETs on the efficiency

Sep 1, 2017 · In addition to the different topologies, an increasing number of grid-connected inverters adopt wide bandgap (WBG) devices such as silicon carbide (SiC). Kranzer et al. [11]

Changes and challenges of photovoltaic inverter with silicon carbide

Oct 1, 2017 · Aimed at the photovoltaic (PV) power system, this study surveys state-of-the-art of PV inverters. The future requirements of PV inverters on efficiency, power density, reliability,

The Silicon Carbide Inverter

Jun 6, 2024 · Silicon carbide power semiconductors have quickly become the go-to choice for electric vehicle inverters due to their superior performance over traditional silicon devices. In

Photovoltaic silicon carbide panels

Photovoltaic silicon carbide panels Why are silicon carbide devices important for solar power inverters? In the PV energy conversion system,silicon carbide devices are playing a vital role

Excellent application case of silicon carbide in distributed

Many solar PV devices rely on various forms of polycrystalline silicon or thin films of silicon, cadmium telluride or copper indium gallium selenide, with conversion efficiencies in the 20% to

Silicon Carbide in Solar Energy Systems: Improve Efficiency

Jul 23, 2025 · Silicon Carbide (SiC) is rapidly transforming solar energy technology by offering superior efficiency, reliability, and sustainability for modern photovoltaic (PV) systems. With

Black Ultra-Thin Crystalline Silicon Wafers Reach the 4

May 31, 2023 · Cutting costs by progressively decreasing substrate thickness is a common theme in the crystalline silicon photovoltaic industry for the last decades, since drastically thinner

6 FAQs about [Silicon Carbide Ultra-Thin Photovoltaic Inverter]

Can silicon carbide transform solar power management?

One materials technology poised to transform solar power management is silicon carbide (SiC). Solar manufacturers use this wonder material to build highly efficient and robust solar inverter systems that turn DC power from photovoltaic (PV) cells into household and business AC power.

What is silicon carbide (SiC)?

Silicon Carbide (SiC) is rapidly transforming solar energy technology by offering superior efficiency, reliability, and sustainability for modern photovoltaic (PV) systems. With increasing global demand for cleaner and renewable energy, SiC technology has emerged as a game-changer, particularly in the design of solar inverters and power modules.

Are silicon carbide inverters the foundation of next-generation high-performance converters?

Silicon carbide (SiC) devices can break through the technical limitations of silicon (Si) devices. Thus, SiC devices are considered as the foundations of next-generation high-performance converters. Aimed at the photovoltaic (PV) power system, this study surveys state-of-the-art of PV inverters.

Can silicon carbide improve the performance of PV inverters?

Nowadays, silicon (Si)-based devices, including Si insulated-gate bipolar transistor (IGBT) and Si diode, are commonly used in inverters. However, over the past four decades, the performance of Si devices has reached its boundary . Recently, silicon carbide (SiC)-based devices are used to improve the performance of PV inverters .

What is a sic PV inverter?

SiC devices are the preferred devices to replace Si devices in these converters. Some demonstrations of SiC PV inverters have revealed that the application of SiC devices is a double-edged sword. Many technical challenges should be overcome to benefit from the excellent performances of SiC device.

What are SiC-based devices used to improve PV inverter performance?

Recently, silicon carbide (SiC)-based devices are used to improve the performance of PV inverters . The prices of SiC diode and metal–oxide–semiconductor field-effect transistor (MOSFETs) decrease by 10% per year. These SiC devices are replacing Si devices for PV inverter applications.

Update Information

- Solar photovoltaic silicon panels

- Photovoltaic high voltage inverter

- Greek brand photovoltaic inverter

- Manila photovoltaic energy storage 300kw inverter manufacturer

- Assembly and assembly of photovoltaic inverter

- Photovoltaic power station inverter into the combiner box

- Huawei Energy Storage Photovoltaic Inverter

- Baku photovoltaic energy storage inverter manufacturer

- Huawei 8kw photovoltaic inverter

- Photovoltaic inverter home decoration design

- Photovoltaic inverter plus wifi

- Photovoltaic micro inverter financing

- The role of inverter in photovoltaic power generation

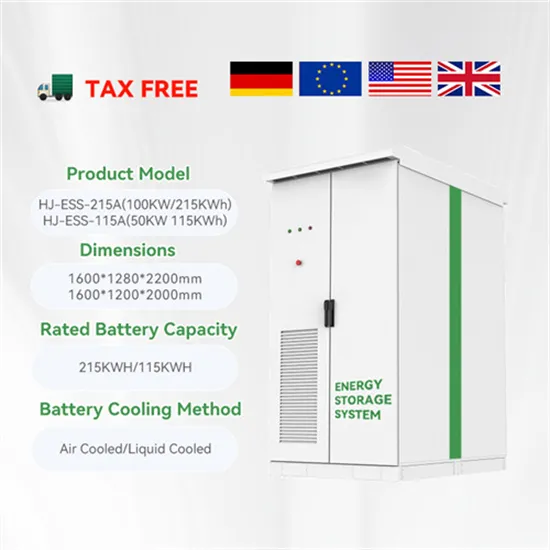

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

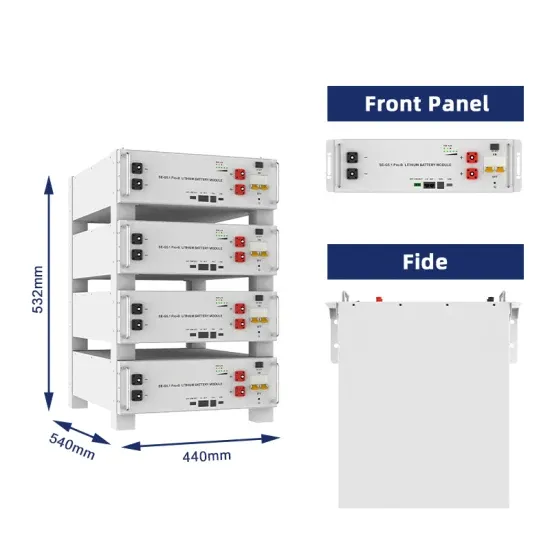

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.