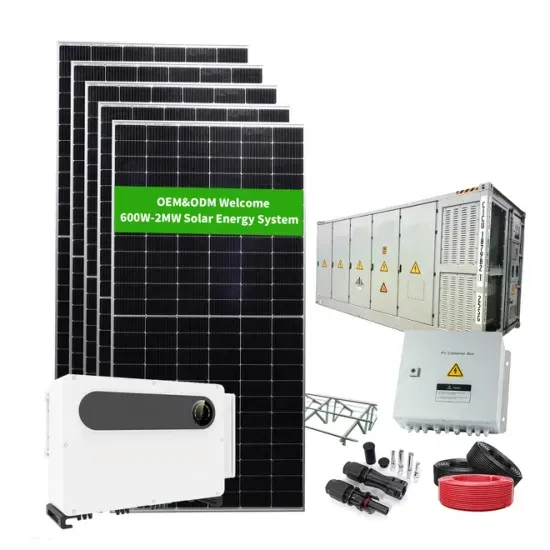

Photovoltaic combiner and photovoltaic combiner box

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

Photovoltaic power station combiner box communication

The input power parameter is one of the key considerations in the selection process. It refers to the maximum input power that the PV combiner box can handle. When selecting,it''s necessary

AC Combiner Box for PV Inverter Systems

The AC Combiner Box is a critical protection and distribution device in photovoltaic (PV) string inverter systems. It connects multiple PV string inverters to the main AC power grid safely and

Photovoltaic AC combiner box classification

When selecting a photovoltaic (PV) combiner box, several key parameters must be considered to ensure the efficient operation and safety stability of the PV power station. How many string

How Does a PV Combiner Box Work? | Power

Apr 23, 2024 · AC PV combiner box is an important part to take over the output of string inverter and the input of AC distribution cabinet or step-up transformer,

Photovoltaic combiner box connected to inverter

How does a solar combiner box work? hotovoltaic (PV) modules into one standard bus. The fibe s are subsequently attached to the PV inverter. According to Northern Arizona Wind &Sun,for

What Does a Solar Combiner Box Do? Complete

Jun 24, 2025 · Bottom Line Up Front: A solar combiner box consolidates multiple solar panel strings into a single output before sending power to the inverter. It

What is Combiner box? The Combiner box in photovoltaic power

Aug 22, 2024 · It is usually installed between the solar panel and the inverter. It is used to collect the current from multiple solar panels onto a cable and then deliver it to the inverter to make

Voltage of the combiner box of the photovoltaic power

Nov 3, 2023 · The Solar combiner box in the photovoltaic power generation system is a wiring device that ensures orderly connection and convergence of photovoltaic modules. This device

Photovoltaic substation combiner box structure

May 3, 2020 · transmitted to the grid through the output line. The main system structure of the distributed photovoltaic power station is shown in Figure 1. transmission power grid line

APPLICATION NOTE DC COMBINER BOX IN

Jul 25, 2025 · External DC combiner boxes are used with central inverters in large-scale solar farms to consolidate thousands of strings and with single-mppt string inverters which can be

Test standards for photovoltaic combiner boxes

Efficiencyis the hallmark of any successful solar installation. Combiner boxes help improve the overall efficiency of the photovoltaic system by optimizing the wiring structure and integrating

What is a photovoltaic power station combiner box

In a photovoltaic system,a combiner box acts as a central hubthat consolidates and manages the direct current (DC) output of multiple solar panels. Its main purpose is to simplify the wiring

6 FAQs about [Photovoltaic power station inverter into the combiner box]

What is PV combiner box in on grid Solar System?

In an on-grid solar system, the PV combiner box is usually in need between the solar panels and inverter to decrease the connecting lines, facilitate maintenance, reduce losses, optimize system structure, and improve the safety and reliability of items. In the solar power system, this component plays an essential role.

What is an AC combiner box for PV inverter?

An AC combiner box is used to connect multiple grid-connected inverters to a single power cabinet. It provides lightning protection and circuit breakers for each inverter output, ensuring safe and convenient access to the power cabinet.

What is a solar combiner box?

Bottom Line Up Front: A solar combiner box consolidates multiple solar panel strings into a single output before sending power to the inverter. It simplifies wiring, enhances safety with overcurrent protection, and reduces installation costs—but it’s typically only needed for systems with four or more panel strings.

What is a PV combiner box?

In a photovoltaic system, the PV Combiner Box is an electrical device used to combine multiple photovoltaic modules (solar panels) generated by the direct current (DC) pooled together and distributed to the inverter, in order to convert the DC power into alternating current (AC) for home, commercial buildings, or grid usage.

How does a solar combination box work?

At this time, the output current is the sum of the currents of all parallel components, and the voltage remains the same as that of individual components. •Inverter connection: The inverter converts the DC power from the solar Combiner Box into AC power, which is supplied to the local power equipment or transmitted to the power grid.

How does a solar combiner work?

Here’s the step-by-step process: The solar combiner takes the output of several solar PV cells and combines them into one line before they go on to the inverter. This process maintains the individual string voltages while adding up the currents, maximizing the power delivery to your inverter.

Update Information

- Brussels photovoltaic power station high quality inverter

- The role of photovoltaic inverter combiner box

- Sao Tome communication base station inverter grid-connected photovoltaic power generation service life

- Micro inverter for photovoltaic power station

- Layout of photovoltaic inverter and combiner box bridge

- Gambia communication base station inverter photovoltaic power generation brand

- 50kW inverter for photovoltaic power station

- Tuvalu Photovoltaic Power Station Inverter

- Inverter production photovoltaic power station

- The photovoltaic inverter is first connected to the power supply

- Rabat communication base station flow battery photovoltaic power generation system bidding

- Design of photovoltaic panel energy storage power station

- Bridgetown Communication Base Station Uninterrupted Power Supply Photovoltaic Power Generation Outdoor Unit

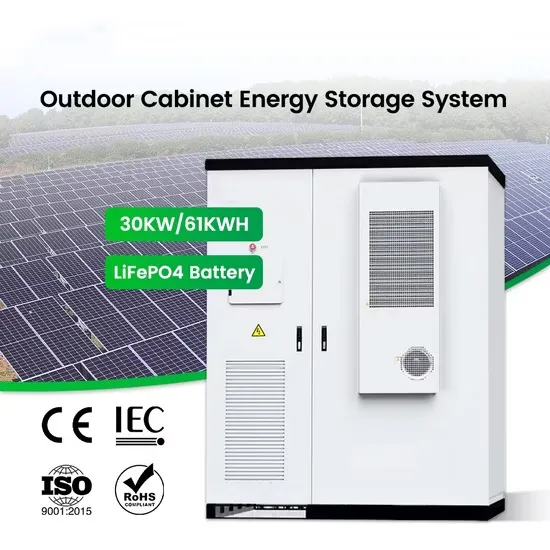

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.