Transportation and Installation Requirements

Jun 28, 2024 · You can connect the DC terminals from the DC main distribution directly to the DC busbars in the inverter. The inputs are fused outside of the inverter, for example in the DC

LCD Screen 1500W 3000W DC 12V to AC 220V 230V

Apr 30, 2025 · Power inverter converts 12V or 24V DC from battery or car lighter to AC 110V or 220V household power, with USB port and AC outlet for fast charging the electronic devices.

Commercial Vehicle Inverters and Sustainable Transport

Commercial vehicle inverters play a crucial role in promoting sustainable transport systems by enabling efficient energy use in electric vehicles (EVs). Modern inverters convert DC power

HD Wave Inverter Installation Guide

Mar 13, 2017 · Appendix C: Inverter Arc Detection and Interruption Appendix D: Replacing and Adding System Components Replacing an Inverter _ Replacing the Safety Switch SolarEdge

StorEdge Three Phase Inverter

Dec 6, 2020 · The inverter cover must be opened only after shutting off the inverter P/ON/OFF switch located at the bottom on the inverter .This disables the DC voltage inside the inverter.

How Do Laptop Inverters Work: A Comprehensive Explanation

Oct 15, 2024 · In the realm of laptop hardware, inverters play a crucial role in converting direct current (DC) power from the battery or power supply into alternating current (AC) power

Solar Power Solutions for 20ft Shipping Containers

Apr 23, 2025 · A: Install micro-inverters or DC optimizers (e.g., Tigo TS4-A-O) to minimize output loss. Q: What certifications are mandatory? A: CE for EU, UL

5. Operation

Apr 23, 2025 · To restart the inverter, switch it off and then switch it on again. High DC ripple is usually caused by loose DC cable connections and/or too thin DC wiring. To clear or prevent

Analysis and Evaluation of DC-Link Capacitors for High

Nov 11, 2023 · Abstract - In electric vehicle (EV) inverter systems, dc-link capacitors, which are bulky, heavy and susceptible to high temperature, can become a critical obstacle to high

Understanding the Functionality of a Laptop Inverter: A Deep

Apr 22, 2025 · What is a Laptop Inverter? A laptop inverter is a crucial device responsible for converting the direct current (DC) power from your laptop''s battery or power supply into

6 FAQs about [DC screen inverter transportation]

Why do LCD screens need an inverter?

Inverters are essential for an LCD screen as they convert DC (Direct Current) from the power supply to AC (Alternating Current), enabling the backlight to function. Without an inverter, the screen would remain dim and unusable because the backlight is what makes the display visible.

How does an LCD inverter work?

In simple terms, an LCD inverter takes the direct current (DC) power from the device’s battery or power supply and converts it into the alternating current (AC) power needed to light up the screen’s backlight. This backlight is what allows you to see the images on the LCD panel. There are two main types of LCD backlights that use inverters:

What is a DC/DC converter?

DC/DC converter features a robust design, a wide range of input voltages, ideal for hybrid/electric vehicle applications. We take great pride in our work and our products. We gladly talk to you about what we do and we gladly help you with any questions you have. We are just an email away so don't hesitate to contact us!

How to transport an inverter?

The inverter comprises a compact enclosure which can be transported using either a long pallet truck, a forklift or a crane fork. Transport using a crane equipped with a suitable harness is also possible. Note that the selected means of transportation must be suitable for the weight of the inverter. The weight of the inverter is: 1800 kg.

What is an ACH inverter?

ACH Inverters The heavy worker High power inverter for hybrid and electric vehicles. With a rugged design for both on-highway and off-highway applications. Read More DC/DC converter features a robust design, a wide range of input voltages, ideal for hybrid/electric vehicle applications.

How does an inverter board work?

An inverter board typically includes a circuit with several key components such as transistors, resistors, capacitors, and sometimes a fuse. These components work together to manage the flow of electricity and generate the necessary voltage to power the screen’s backlight.

Update Information

- Islamabad DC Screen Inverter Factory

- Inverter is suitable for DC voltage regulation

- Mechanical inverter DC 12V

- DC water pump inverter

- Slovakia DC inverter zlb-250

- DC Pulse Inverter

- How big is the DC panel inverter usually

- High Voltage DC Step-Down Inverter

- Looking for 36v DC to 220v inverter

- Iraq DC screen battery cabinet equipment

- Does the inverter have a DC output

- DC AC inverter bridge

- DC to AC inverter design

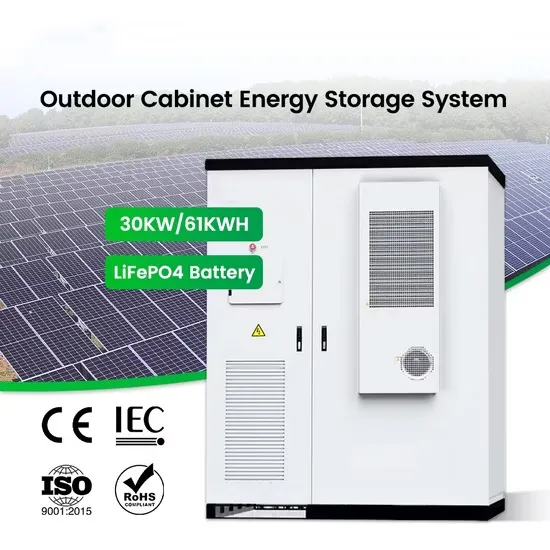

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.