How to calculate the bus capacitance of photovoltaic

Objective: To determine the optimum size of a dc-link capacitor for a grid connected photovoltaic inverter. Methods: Dc-link capacitors are considered as one of the sensitive parts of the grid

How to calculate the bus capacitance of photovoltaic

In this video, you will learn how to calculate the DC Bus Capacitor value for a three-phase inverter. #inverter #electric #electronic #electrical #engineeringfunda #engineering #hardware.

Virtual inertia extraction from a DC bus capacitor in a

Dec 1, 2024 · The virtual frequency is obtained directly from the DC bus voltage of the inverter and this is achieved by allowing the DC link capacitor voltage to swing boarder than the grid

BUS Capacitor Function in Photovoltaic Inverters: The

Let''s face it - when most people think about photovoltaic systems, they imagine shiny solar panels, not the BUS capacitor function in photovoltaic inverters. But here''s the kicker: this

Photovoltaic inverter bus capacitor discharge

About Photovoltaic inverter bus capacitor discharge As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic inverter bus capacitor discharge have become critical to

DC-Bus Design with Hybrid Capacitor Bank in Single

Oct 15, 2019 · In this paper, a hybrid capacitor bank, including film capacitors and the LC resonant filter with small inductor is proposed for the single-phase grid-tied PV inverter as shown in Fig. 1.

Research on DC Bus Capacitance Health Status by Capacitance

Mar 30, 2024 · The photovoltaic centralized inverter is the core component of the photovoltaic power generation system, and its health status is critical to the output power quality. In PV

A DC Bus Capacitor Design Method for Various Inverter

Feb 21, 2024 · Abstract - This paper involves the selection and sizing of the appropriate type of dc bus capacitor for various applications utilizing PWM operated three-phase voltage source

Optimization Tool for Dc-Link Capacitor Bank Design in PV Inverters

May 30, 2019 · The development of a tool is presented for optimizing dc-link capacitors design in PV inverters. Reliability of power converters is well known to be one of the bottlenecks for

A single phase multi-string PV inverter with minimal bus capacitance

Oct 10, 2009 · This minimization of capacitance is not possible in a single-stage string inverter as a large input capacitor must directly decouple the PV string from the pulsating single phase

Digital resonant controller for dual-stage photovoltaic inverter

May 18, 2016 · Electrolitic capacitors of dc-bus link normally present the lowest mean time between failures among other electronic components of photovoltaic (PV) inverters. This

The bus voltage of photovoltaic inverter is too high

In standalone and grid-connected PV structures,DC-Bus capacitor is the extremely important passive component. Harmonics and power factor reductionoccur in single-phase PV inverters

Digital resonant controller for dualâ stage photovoltaic

Dec 23, 2020 · Abstract: Electrolitic capacitors of dc-bus link normally present the lowest mean time between failures among other electronic components of photovoltaic (PV) inverters. This

BUS Capacitor Function in Photovoltaic Inverters: The

Why Your Solar Inverter''s BUS Capacitor Matters More Than You Think Let''s face it - when most people think about photovoltaic systems, they imagine shiny solar panels, not the BUS

Optimal integration of photovoltaic sources and capacitor

Jan 21, 2025 · This paper introduces the Efficient Metaheuristic BitTorrent (EM-BT) algorithm, aimed at optimizing the placement and sizing of photovoltaic renewable energy sources

Evaluation of the DC bus link capacitors and power transistor

Oct 15, 2020 · To achieve useful, fair, and cost-effective design qualification and type approval testing for PV inverters, two procedures were developed and demonstrated to evaluate the

DC-Bus Ripple Current Characterization of Three-Phase

Sep 6, 2024 · Abstract—The selection and sizing of the dc-bus capacitor for applications utilizing three-phase PWM operated voltage source inverters (VSIs), such as grid connected

Digital resonant controller for dual‐stage photovoltaic inverter

Electrolitic capacitors of dc-bus link normally present the lowest mean time between failures among other electronic components of photovoltaic (PV) inverters. This manuscript proposes

A single phase multi-string PV inverter with minimal bus capacitance

Oct 6, 2009 · The multi-string photovoltaic (PV) inverter is of interest for building grid-connected PV systems because it offers a number of advantages compared to conventional centralized

A DC bus capacitor design method for various inverter

Sep 20, 2012 · This paper involves the selection and sizing of the appropriate type of dc bus capacitor for various applications utilizing PWM operated three-phase voltage source

Photovoltaic Inverter DC Bus Capacitor: The Unsung Hero in

Meta Description: Discover why the DC bus capacitor is critical for photovoltaic inverter efficiency. Learn about common failure triggers, performance optimization strategies, and emerging

DC Link Capacitor Calculation for Inverter

Oct 5, 2024 · Learn how to calculate the DC link capacitor for inverters, taking into account power rating, voltage ripple, switching frequency, and load dynamics. Ensure your inverter operates

PV inverter performance and reliability: What is the role of the bus

Nov 7, 2013 · The bus capacitor is generally considered to be among the least reliable components of the system, so we have simulated how the degradation of bus capacitors

6 FAQs about [Photovoltaic inverter BUS capacitor]

Which capacitor is used in the DC bus of an inverter?

Generally electrolytic and film capacitors are used in the dc bus of an inverter. Aluminum electrolytic capacitors have high capacitance to volume ratio. This fact makes them ideal to decrease the dc bus voltage ripple (create a stiff dc bus voltage) and introduce high energy storage.

What is a hybrid capacitor bank for a grid-tied PV inverter?

In this paper, a hybrid capacitor bank, including film capacitors and the LC resonant filter with small inductor is proposed for the single-phase grid-tied PV inverter as shown in Fig. 1. CE is the electrolytic capacitor bank and, LE is the inductor with reduced size, thus LECE represents the LC resonant filter. CF represents the film capacitor.

What is DC BUS capacitor design method for power converter topologies?

CONCLUSION Dc bus capacitor design method for various power converter topologies involving two-level, three-phase inverters has been proposed. The design starts from selecting the power electronic converter topologies, progresses to the choice of efficient PWM methods, and finally iterates on the capacitor size.

What is a DC BUS capacitor?

The dc bus capacitor (Cdc) is utilized to both reduce the voltage ripple and bypass the current ripple. The topology of an application dictates the type and size of the appropriate capacitor, since it determines the ripple current frequency spectrum characteristics. Then, the current ripple determines the voltage ripple. Figure 1.

What is the DC bus voltage of a film capacitor?

The dc bus voltage is selected as 800 V (±400 V). A film capacitor with the following specs is chosen; 220 μF, 600 V, 100 A rms, ESR=1 mΩ, Rth=8.4 °C/W (FFVE6K0227K) . Two capacitors are connected in series (midpoint gives the neutral terminal), yielding 110 μF equivalent dc bus capacitor.

Which DC-bus should be used in a two-stage PV inverter?

The stable DC-bus should be achieved for the interface between the MPPT DC/DC converter and single-phase inverter in the two-stage PV inverter. Moreover, the stable DC-bus is desired for future integration with energy storage unit. However, the single-phase inverter suffers from the double grid frequency harmonic on the DC-bus.

Update Information

- Photovoltaic inverter three-phase energy storage capacitor

- 500kw photovoltaic inverter capacitor quantity

- West Africa Photovoltaic Power Generation Equipment Inverter

- Huawei Photovoltaic Smart Inverter

- 2120w photovoltaic panel connected to 12v inverter

- Spi photovoltaic inverter

- Astana repair photovoltaic inverter manufacturer

- Somalia photovoltaic module inverter manufacturer

- Silicon Carbide Ultra-Thin Photovoltaic Inverter

- Photovoltaic energy storage inverter structure

- 10 000 watt photovoltaic inverter

- Genuine photovoltaic inverter

- Photovoltaic development components energy storage inverter

Solar Storage Container Market Growth

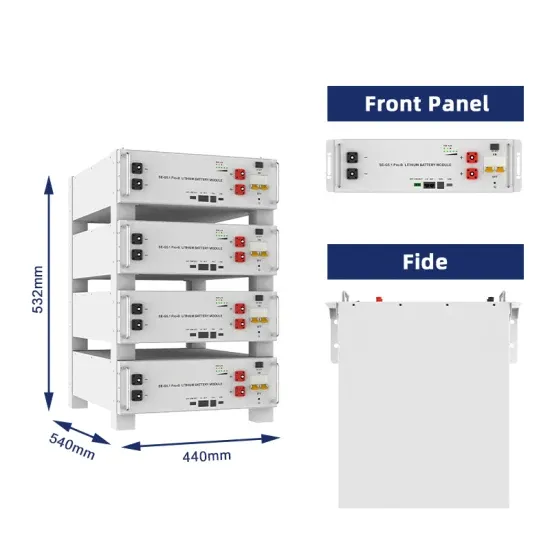

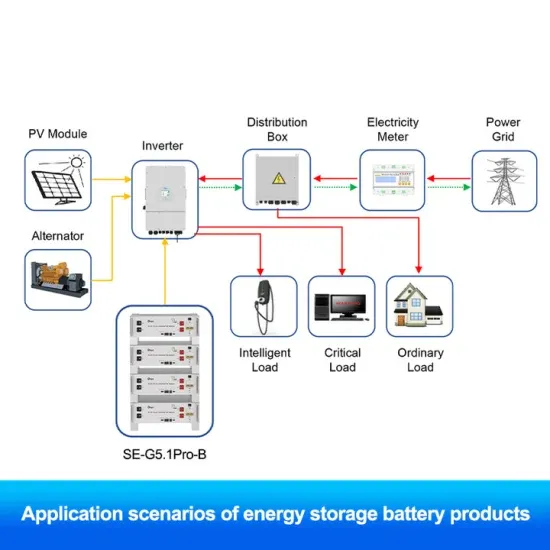

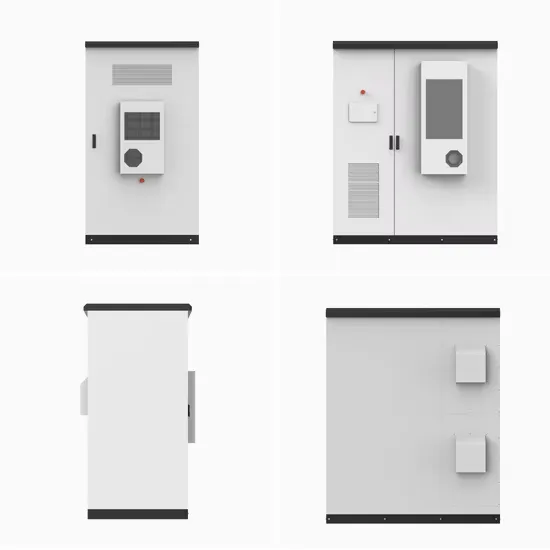

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.