Phase change materials for battery thermal management

Jan 1, 2023 · The simple structure of the phase change materials (PCMs) with no moving parts and high latent capacity has made them suitable candidates for the battery thermal

Potential applications of phase change materials for batteries

Oct 1, 2022 · Advantages and disadvantages of different methods of TMS cooling for the EV are presented. Enhanced thermal management systems based on PCM are investigated. Number

Solid-liquid phase change materials for the battery

Jun 28, 2022 · uid cooling strategy with phase change materials for Li-ion batteries optimized using response surface methodology. Applied Energ Z, Pan W. Thermal conductivity

Thermal management of Li-ion batteries using phase change

Mar 1, 2025 · Phase change materials (PCMs) have recently emerged as a promising passive cooling technology for lithium-ion batteries, offering high latent heat capacity, constant

Recent developments in solid-solid phase change materials

Jun 1, 2024 · In recent papers, the phase change points of solid-solid PCMs could be selected in a wide temperature range of −5 °C to 190 °C, which is suitable to be applied in many fields,

Potential applications of phase change materials for batteries

Oct 1, 2022 · In order to prolong the cycle life of the battery pack for electric vehicles or hybrid electric vehicles, phase change materials (PCMs) are employed effectively for the battery

Thermal Management Techniques for Lithium-Ion

Mar 19, 2024 · This cluster illustrates that phase change materials are widely used in lithium-ion batteries as a high latent heat storage material and the combination of this passive cooling

A critical review of thermal management systems for lithium-ion batteries

Aug 19, 2025 · Lithium-ion batteries have become the preferred power source for electric vehicles with superior properties and excellent performance. Chemical reactions within the battery

Recent advances in phase change materials-based battery

Nov 30, 2023 · Electric vehicles'' lithium-ion batteries (LIBs) generate abundant heat during charging and discharging. Controlling the batteries'' temperature within the appropriate range

Battery thermal management with phase change materials

Dec 19, 2024 · According to the difference of the heat transfer medium, the lithium-ion battery thermal management can be divided into three types: air cooling, liquid cooling and phase

Thermal management of Li-ion batteries using phase change

Mar 1, 2025 · With the rising adoption of lithium-ion batteries in electric vehicles and renewable energy storage, effective thermal management has become imperative for safe and optimal

Battery thermal management with phase change materials

Dec 19, 2024 · The thermal management system with PCM material cooling is to absorb the heat of the battery by latent heat of PCM material in the phase change process and prevent the

A review on phase change materials for different applications

Jan 1, 2021 · PCMs have an infinite number of applications for inactive as well as adaptive heating/cooling as a combined portion of the cascaded thermal energy structure (TES) [8].

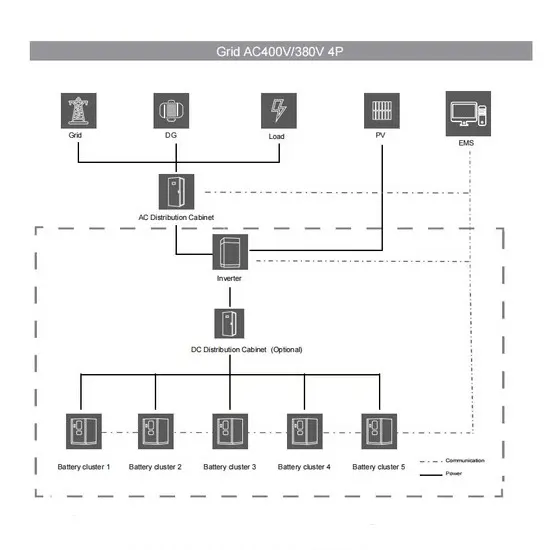

Thermal management technology analysis of energy storage

In summary, air cooling, liquid cooling and phase change cooling in energy storage thermal management have their advantages and disadvantages. When choosing the right cooling

Thermal Management Techniques for Lithium-Ion

Mar 19, 2024 · Abstract: Thermal management systems for lithium-ion batteries based on the cooling and heating of phase change materials have become a popular research topic.

A Review of Different Types of Battery Cooling Systems

May 31, 2023 · This paper reviews different types of cooling systems used in lithium-ion batteries, including air cooling, liquid cooling, phase change material (PCM), heat pipe, thermo-electric

Research progress of enhancing battery safety with phase change

Jan 1, 2024 · Several established battery thermal management systems (BTMS) are available, including air cooling [21, 22], liquid cooling [[23], [24], [25]], heat pipe [[26], [27], [28]] and

Mitigating thermal runaway in EV batteries using hybrid

By inte-grating various technologies, such as batteries, hydrogen storage, ultracapacitors (UCs), and thermo-mechanical energy storage, HESS can meet a wide range of energy demands,

A review of thermal management for Li-ion batteries:

Jul 1, 2021 · This paper reviews the advantages and disadvantages of state of the art (traditional) thermal cooling system. In this paper, we have reviewed separately cell, module, and pack

Thermal management technology of power lithium-ion batteries

Dec 1, 2020 · In this context, this paper reviews two types of battery thermal management systems (BTMS) based on phase transition principle, including the thermal management

Advancements and challenges in battery thermal

Mar 1, 2025 · The contribution of this work lies in synthesizing recent advancements, identifying current challenges, and suggesting future research directions. Understanding and advancing

Disadvantages of choosing lead-acid batteries for liquid

In this article,I will discuss the advantages and disadvantages of nine types of battery energy storage: Sealed Lead Acid,Lithium Batteries,and others. Sealed Lead Acidbatteries have

Battery Phase Change Energy Storage Cooling Disadvantages

Higher enthalpy of phase change is desirable for PCM to enable storage of a bundle of energy into a small volume for achieving greater energy density storage. It is better

Research progress on efficient thermal management system

Nov 5, 2023 · This review classifies the existing concepts of thermal management for EVs based on phase change technology and reviews the development of each technology to

Hybrid PCM-based thermal management for lithium-ion batteries

Dec 1, 2023 · As the demand for electric cars (EVs) and hybrid electric vehicles (HEVs) grows, effective thermal management of lithium-ion batteries becomes more important. The use of

Phase change materials for battery thermal management of

Sep 1, 2022 · This work consists of the discussions on battery thermal management systems using phase change materials, enhancement of Phase Change Materials'' thermal conductivity,

An overview of phase change materials on battery

Dec 1, 2024 · Abstract Phase change materials (PCMs) bring great hope for various applications, especially in Lithium-ion battery systems. In this paper, the modification methods of PCMs and

Research progress on power battery cooling technology for

Feb 1, 2020 · The phase change materials of solid-vapor and liquid-vapor phase deformation are due to their phase transition. which affects energy storage system stability and is still unable to

Challenges in thermal management of lithium-ion batteries using phase

Oct 20, 2024 · Phase change materials (PCMs) absorb/release latent heat of fusion during the melting/solidification process also this study explores the use of PCMs in Li-ion battery thermal

6 FAQs about [Battery Phase Change Energy Storage Cooling Disadvantages]

Are phase change materials a viable passive cooling technology for lithium-ion batteries?

Phase change materials (PCMs) have recently emerged as a promising passive cooling technology for lithium-ion batteries, offering high latent heat capacity, constant operating temperatures during phase change, and a lightweight compact structure. However, issues like low thermal conductivity restrict heat transfer and necessitate enhancement.

Can phase change materials be used in battery thermal management?

The research on the application of phase change materials used in the battery thermal management is late. In 2004, Al-Hallaj et al firstly applied phase change materials in lithium-ion battery thermal management system of an electric scooter.

What are the disadvantages of a PCM battery cooling system?

The key downside is their low thermal conductivity, which restricts heat transfer rates. The low thermal conductivity hinders both the heat absorption from the battery and its rejection to the ambient, thereby reducing the PCM's effectiveness for battery cooling applications with high heat generation rates or rapid cycling .

What is the role of phase change materials in energy storage?

When there is time delay or mismatch between producing energy and energy demand, thermal energy storage provides a great solution. Furthermore, phase change materials (PCM) are considered to be promising thermal storage materials for adjusting the time delays associated with energy supply and demand.

How does air cooling affect lithium ion batteries?

Air cooling is a widely used method for thermal management of lithium-ion batteries, particularly in low-power applications . In high-power applications, the high charging and discharging rates of the battery can lead to significant heat generation, which may reduce the battery's efficiency and lifespan if not properly managed.

Can a cooling system improve the safety of Li-ion battery packs?

An alternative cooling system to enhance the safety of Li-ion battery packs. Journal of Power Sources, 194(2), 1105-1112. Duan, X., & Naterer, G. F. (2010). Heat transfer in phase change materials for thermal management of electric vehicle battery modules. International Journal of Heat and Mass Transfer, 53(23-24), 5176-5182.

Update Information

- Phase change energy storage price in Addis Ababa

- Liquid Cooling Energy Storage Battery Station 20wmh Price

- Outdoor Energy Storage Liquid Cooling Battery Cabinet

- Prices of phase change energy storage in Belgium

- 12V energy storage battery advantages and disadvantages

- Russian phase change energy storage system manufacturer

- 6MW energy storage battery container liquid cooling system

- Design a phase change energy storage system

- Phase change energy storage prices in Valparaiso Chile

- Energy Storage Battery Container Liquid Cooling System Manufacturers Ranking

- Dakar Phase Change Energy Storage System Production Plant

- New Delhi Phase Change Energy Storage System Supplier

- Damascus phase change energy storage device

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

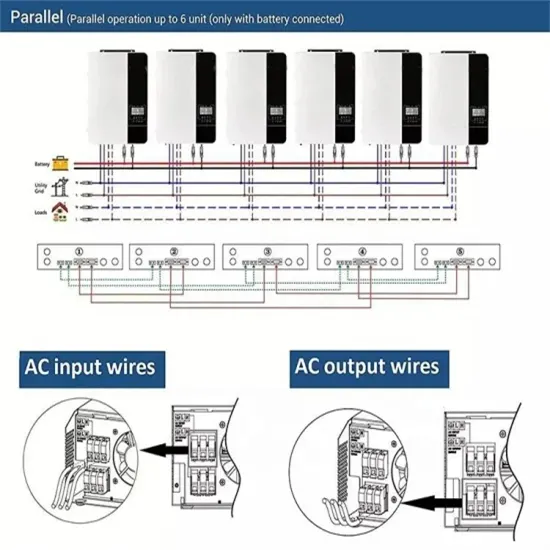

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.