Looking for Solar Panel Production Line?

Feb 17, 2022 · Ooitech, Full Automatic solar panel manufacturing equipment supplier, producing solar panel Making Machines and production lines at Good prices, including Assembly and

PV Module Testing Machines | Solar Equipment | Horad

Jan 16, 2025 · Our portfolio includes not only automatic solar panel production lines, but also individual equipment for PV modules production, from glass loading equipment at the

Price list of photovoltaic panel frame assembly machines

Nov 30, 2023 · China Solar Panel Framing Machine wholesale - Select 2024 high quality Solar Panel Framing Machine products in best price from certified Chinese Machine For Metal

Double-glass Solar Module Machines | PV Module Assembly

Jan 16, 2025 · Our portfolio includes not only automatic solar panel production lines, but also individual equipment for PV modules production, from glass loading equipment at the

How much does the photovoltaic panel production line equipment cost

Specific price range Taking into account the above factors, the total investment for a photovoltaic panel production line equipment is roughly between 30 million and 150 million RMB. This

Price list of photovoltaic panel frame assembly machines

Nov 30, 2023 · Developments in solar panel production machines have been driven by the need for higher efficiency and lower costs. One of the most significant developments is the use of

5 FAQs about [Price of automatic photovoltaic panel assembly equipment]

How much does a solar machine cost?

Machine Solar Panel Solar Machine Panel Making 5mw 10mw 20mw 30mw 50mw 60mw Machine To Make Solar Panel Solar Panel Production Line Turneky Solution Project. US $25000-$180000/ Set. 10 Sets (Min. Order) CN Wuhan Sunic Photoelectricity Equipment Manufacture Co., Ltd. 12 YRS.

Where are solar panel making machine suppliers?

There are 2,056 solar panel making machine suppliers, mainly located in Asia. The top supplying countries or regions are China, India, and Vietnam, which supply 99%, 1%, and 1% of solar panel making machine respectively. Solar panel making machine products are most popular in Domestic Market, Africa, and Southeast Asia.

How many solar panel production lines are there?

Since 2014, we supplied more than 30 solar panel production line all over the world. And aslo we have more than 20 years experience in laser industrial. We have R&D in Wuhan of China and Factory in Wuxi of China. We will help our customer start new solar panel factory, provide semi and full automatic solar panel making machines.

What is solar panel laminating machine?

Solar Panel Laminating Machine is one of the most critical processes in the solar panel manufacturing production flow, it ensures the quality of solar panel. trim the edge of the solar panels, cut the extra parts like back sheets and eva. A constant temperature and humidity room for solar panel Curing, dry the silicone glue.

What is solar panel making machine?

solar panel making machine help in achieving energy-independence by utilizing the power of the sun. solar panel making machine use captured sunlight to create concentrated solar-powered or photovoltaic cells which are later converted into the forms needed. These PVs can be installed on the roofs hence eliminating the need for land.

Update Information

- Praia automatic solar photovoltaic panel production equipment

- Liberia photovoltaic panel equipment BESS price

- Photovoltaic panel assembly equipment manufacturer

- Black Mountain photovoltaic module equipment price

- Niamey Industrial Photovoltaic Panel BESS Price

- Apia rooftop photovoltaic panel BESS price

- Photovoltaic panel container installation price

- Contract price of a rooftop photovoltaic panel

- Turkmenistan photovoltaic panel greenhouse BESS price

- Mongolia monocrystalline photovoltaic panel price

- Kiribati solar photovoltaic panel factory direct selling price

- Photovoltaic panel full set detailed price

- 100m photovoltaic panel price

Solar Storage Container Market Growth

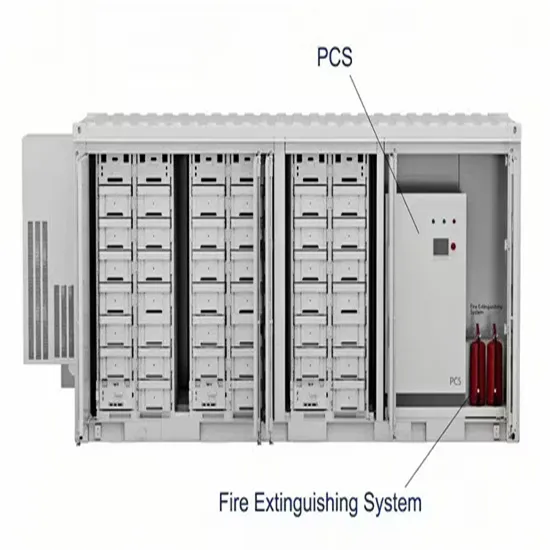

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

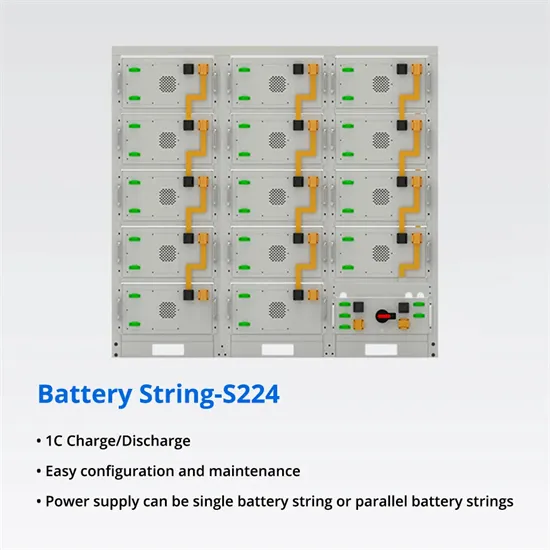

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.