What Is Borosilicate Glass and How Does It

May 2, 2025 · Borosilicate glass offers superior thermal resistance, durability, and chemical stability compared to regular glass, making it ideal for demanding

High Quality Quartz Glass Rod Fire Resistant Optical Glass Rod

1. Excellent High-Temperature Resistance *High upper limit of high temperature resistance: Long term use temperature can reach 1000-1200 ℃, short-term can withstand high temperature

Customized Quartz Glass High Temperature Resistance Optical Glass

1. Excellent High-Temperature Resistance *High upper limit of high temperature resistance: Long term use temperature can reach 1000-1200 ℃, short-term can withstand high temperature

Borosillicate glass (Pyrex) vs Quartz (SiO2):

May 28, 2015 · Page 1 of 2 - Borosillicate glass (Pyrex) vs Quartz (SiO2): - posted in ATM, Optics and DIY Forum: The Youngs modulus (stiffness per area) of Quartz is about 71 vs 63 for

(PDF) Float, borosilicate and tellurites as cover

Sep 21, 2021 · In this work, we describe the production of prototypes of four solar modules made using borosilicate, zinc-tellurite, Pr3+ doped zinc-tellurite, and

What is the Difference Between Solar Photovoltaic Glass and Float Glass?

May 30, 2024 · Photovoltaic (PV) glass, used in solar panels, features special coatings for efficiency and durability, while float glass, used in construction and automotive industries, is

Understanding Borosilicate Glass And Its Properties

Dec 4, 2024 · Role in Lighting and Electronics Borosilicate glass plays a significant role in modern lighting and hardware. Its uncommon heat resistance and optical clarity make it crucial in

Borosilicate Glass Applications in Photovoltaic Systems

Jul 3, 2025 · Initially developed for laboratory glassware, borosilicate glass has found its way into various high-tech applications, with solar energy being one of the most promising fields. The

Efficient Light Transmission through Borosilicate Glass

Jul 3, 2025 · Borosilicate Glass Light Transmission Background Borosilicate glass has been a cornerstone material in various industries for over a century, renowned for its exceptional

Properties of a Solar Alumina-Borosilicate Sheet Glass

Sep 24, 2018 · Some of the properties of the glass are shown in Table 2. The glass was designed to be compatible with the fusion sheet-forming process and to be melted at high rates for low

High Temperature Resistant Round Glass Cover High

1. Excellent High-Temperature Resistance *High upper limit of high temperature resistance: Long term use temperature can reach 1000-1200 ℃, short-term can withstand high temperature

Quartz Glass VS High Borosilicate Glass

Sep 1, 2024 · The main differences between quartz glass and high borosilicate glass are their composition, temperature resistance, hardness, heat conduction properties, corrosion

High Precision Flat Quartz Glass Corrosion Resistant UV Optical Glass

1. Excellent High-Temperature Resistance *High upper limit of high temperature resistance: Long term use temperature can reach 1000-1200 ℃, short-term can withstand high temperature

Exploring the dielectric polarization and ionic conduction

Oct 1, 2023 · The dielectric and electrical behavior of a sodium silicate glass (soda-lime-silica; SLS) and a sodium borosilicate glass (D263T) are systematically and comprehensively

What is Special about High Borosilicate Glass

6 days ago · Explore the differences between high borosilicate glass and regular glass—durability, thermal resistance, and uses in labs, cookware, and more.

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency. Advances in glass compositions,

The Ultimate Guide to High Borosilicate Glass vs Regular Glass

Jul 3, 2025 · Among the many types of glass, high borosilicate glass and ordinary glass (commonly known as soda-lime glass) stand out due to their unique properties and applications.

Glass Transition Temperature and Borosilicate Chemistry

Jul 3, 2025 · In the context of borosilicate chemistry, the glass transition temperature plays a vital role in determining the properties and performance of these specialized glasses. Borosilicate

Sem título de diapositivo

Jan 4, 2015 · The mirror glass substrate is usually 3 – 4 mm thick soda-lime float glass (not borosilicate) of rather low Fe content (white glass) compared to normal float glass and thus

Borates in borosilicate glass

Feb 18, 2025 · Borates in borosilicate glass Borosilicate glass is the foundation for all heat-resistant glass applications and the myriad of products they make possible—from halogen

What is Borosilicate Glass? Composition, Properties

Borosilicate glass is a specialized engineering material renowned for its exceptional thermal stability and chemical resistance. Composed primarily of silica (SiO₂) and boron trioxide

Laser doping selective emitter with thin borosilicate

Feb 5, 2025 · In this paper, the laser doping has been promoted by optimizing the boron diffusion to maintain a high concentration of boron atoms in a thinner borosilicate glass (BSG) layer.

Is photovoltaic glass high borosilicate

Demand for solar photovoltaic glass has surged due to growing interest in green energy. This article explores types like ultra-thin, surface-coated, and low-iron glass used in solar cells and

Borates in borosilicate glass

Feb 18, 2025 · Borates in borosilicate glass Borosilicate glass is the foundation for all heat-resistant glass applications and the myriad of products they make possible—from halogen

Screen-Printed Borosilicate Glass Derived from

Jul 8, 2020 · Borosilicate glass films deposited by chemical vapor deposition are used as boron dopant sources in silicon solar-cell manufacturing, to reduce

Why High Borosilicate Glass Stands Out for Heat Resistance

May 4, 2025 · High borosilicate glass offers superior heat resistance and durability, preventing cracking under extreme temperatures. Ideal for cookware and drinkware.

Borosilicate Glass | Formula, Properties & Application

Aug 4, 2025 · Explore borosilicate glass, its chemical composition, manufacturing process, properties, applications, pros & cons in our comprehensive guide.

6 FAQs about [Is photovoltaic glass high borosilicate ]

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Why are borate glasses more brittle than silicate glasses?

Borate glasses, despite their energy efficiency, are generally more brittle than silicate glasses. The lower melting temperature leads to a glass network with reduced viscosity and network connectivity, which in turn compromises mechanical strength. environmental conditions, where long-term stability is essential. For example, borate

What is photovoltaic glazing?

The photovoltaic (PV) glazing technique is a preferred method in modern architecture because of its aesthetic properties besides electricity generation. Traditional PV glazing systems are mostly produced from crystalline silicon solar cells (c-SiPVs).

Are transparent photovoltaics good for the environment?

The use of transparent photovoltaics in the US was found to have both environmental and cost benefits due to the combined reduction in building energy consumption and electricity production. Soiling of solar cover glass can result in a significant loss of electrical output of PV panels.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

Can low-cost solar cells be used for PV glazing?

Traditional PV glazing systems are mostly produced from crystalline silicon solar cells (c-SiPVs). The development of low-cost PV cells for the production of cost-effective and energy-saving glass systems has been of great interest.

Update Information

- How high a temperature can photovoltaic glass withstand

- High calcium stone for photovoltaic glass

- Photovoltaic glass industry

- Photovoltaic panel glass weight

- Global Photovoltaic Glass Manufacturers Status

- Cuban photovoltaic glass company

- Photovoltaic glass photovoltaic modules

- Vientiane A photovoltaic glass

- Photovoltaic glass storage and cooling

- Morocco double glass photovoltaic curtain wall customization company

- Household photovoltaic panel inverter high power

- Libreville single-glass photovoltaic module glass

- Photovoltaic glass greenhouse installation

Solar Storage Container Market Growth

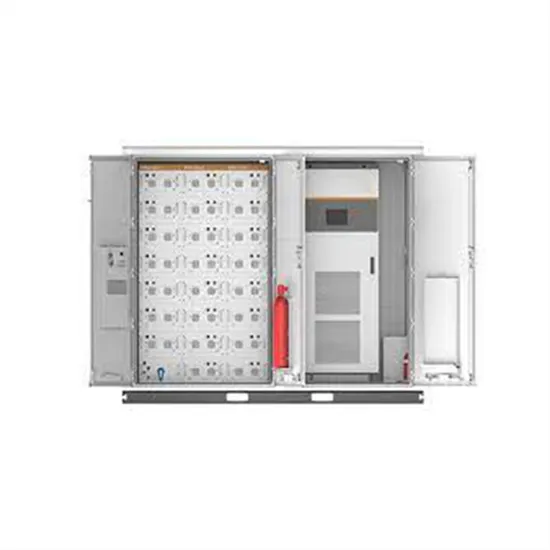

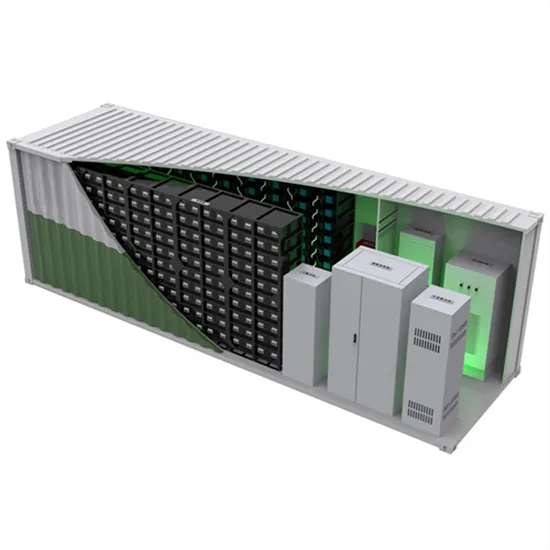

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

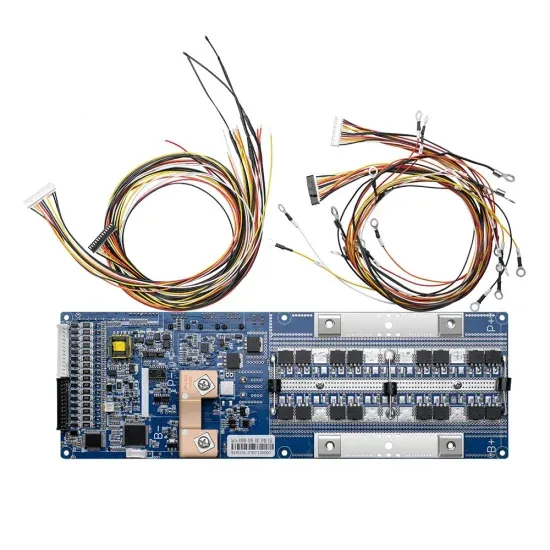

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.