App Note

Feb 2, 2023 · Although a battery is called a ''12 volt'' battery, its voltage varies from about 12.6 volts down to 10 volts when it is discharging and can rise to 15 or 16 volts during charging. It is

How Many Watts Does a Car Battery Charger Use

1 day ago · A car battery charger typically uses 50 to 1,000 watts, depending on its type and charging speed. But why such a wide range? Let''s break it down. Many assume all chargers

Parallel vs. Series: Connecting Cells To Build A

Jun 5, 2020 · Learn how to connect 3.2V 180Ah LiFePO4 battery cells in parallel & series to build the optimal voltage potential and amp-hours for our DIY

Taming the Beast: Batteries for Ships

Jul 19, 2021 · The vessel can run with one diesel genset at 85-90 per cent load at sea and in ports. While at port, excess energy generated is used to charge the batteries. A second

How Many Volts Is a Car Battery Charger

1 day ago · A car battery charger typically delivers 6V, 12V, or 24V, depending on your vehicle''s needs. Most modern cars use 12V systems, but heavy-duty trucks may require 24V.

An essential guide to Hearing Aid Batteries

Nov 16, 2020 · Like all batteries, zinc air hearing aid batteries will slowly lose charge over time (less than 10% per year with a tab). To get the most from your batteries, purchase batteries

How to charge all lead acid batteries; how to

Apr 25, 2024 · Those batteries that are used in deep discharge cycling mode can be charged up to 2.45 volts/cell (14.7V for a 12V battery) to get the highest

What is the maximum volt of container energy storage?

Feb 25, 2024 · Container energy storage, often utilized in renewable energy integration, electric vehicle charging stations, and grid stabilization, relies on various technologies, including

What Voltage Do Electric Cars Run On? | Electric

Mar 11, 2025 · The final word on what voltage EVs use Electric vehicles typically use high voltages, ranging from 400 to 800 volts, which power the vehicle''s

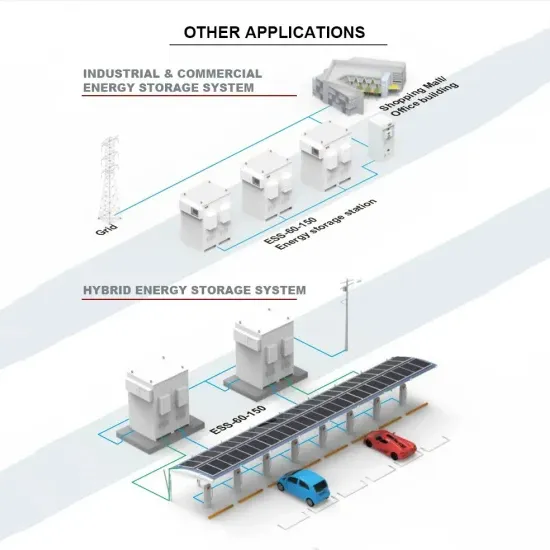

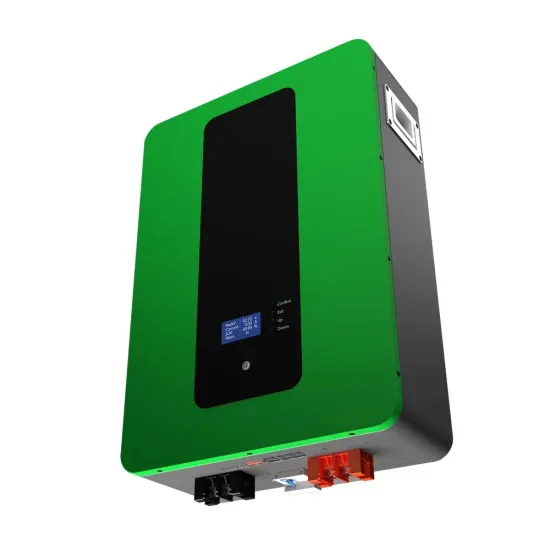

BATTERY ENERGY STORAGE SYSTEM CONTAINER, BESS

Apr 8, 2024 · Battery Energy Storage System (BESS) containers are a cost-effective and modular solution for storing and managing energy generated from renewable sources. With their ability

Charging LiFePO4 Batteries: A Guide by Battle

Oct 16, 2023 · Although you don''t need to purchase a specific charger for Battle Born LiFePO4 batteries, it is essential that you check that your charger has

How many volts are usually in an energy storage container

AC Output volt. 1000A. Max. DC current. Container energy storage is usually pre-installed with key components such as batteries, inverters, monitoring systems and the corresponding

Common specifications and dimensions of energy

Battery energy storage system (BESS) have been used for some decades in isolated areas, especially in order to sup-ply energy or meet some service demand [1]. There has [4, 5].

how many volts are best for container battery energy

The Architecture of Battery Energy Storage Systems Before discussing battery energy storage system (BESS) architecture and battery types, we must first focus on the most common

How to store lead acid batteries – BatteryGuy

May 3, 2024 · If the battery has been stored in the cold bring it to room temperature (this can take several hours for the battery to warm right through). Check the manufacturers data sheet to

6 FAQs about [How many volts are used to charge container batteries]

What is the minimum voltage for a 2V battery?

A lead-acid 2V cell end of discharge minimum voltage is 1.75V. The battery must never be over-discharged to exceed 80% of the Ampere-hour (Ah) capacity. On completion of the discharge, the battery must be placed on the charging cycle. Once the battery is fully charged the monthly check to be carried out.

Can a battery be overcharged?

The battery must never be over-discharged to exceed 80% of the Ampere-hour (Ah) capacity. On completion of the discharge, the battery must be placed on the charging cycle. Once the battery is fully charged the monthly check to be carried out. Do not leave the batteries in a state of discharge for a long period.

How to test a 12V battery?

During charging: it should take less current compare no normal charging current level. Idle condition: For 12V battery - Terminal voltage above or equal to 12.6V or equal to about the maximum charging voltage. And cell voltage becomes constant. Best way: Measure the electrolyte with the help of a hydrometer.

What are the requirements of a battery?

The requirement of batteries is governed by Part-D, Regulation 43, and Chapter 2-1 of SOLAS. It should be automatically connecting to ESB (Emergency Switch Board) when the main power source fails. Immediately supply power to minimum services specified for emergency sources. The battery should not discharge more than 12% of the nominal voltage.

What is a battery energy storage system (BESS) container?

This includes features such as fire suppression systems and weatherproofing, ensuring that the stored energy is safe and secure. Battery Energy Storage System (BESS) containers are a cost-effective and modular solution for storing and managing energy generated from renewable sources.

How often should a battery charger be checked?

The following checks should be carried out daily: Battery charging voltage should be checked. The insulation level by earth lamps or megger meter at the Battery Charger unit. All batteries should be renewed every 2 to 3 years or earlier if required.

Update Information

- How many volts and amperes does a container generator have

- How many volts are small energy storage batteries usually

- How to charge the lithium battery in the base station battery cabinet

- How long does it take to charge solar on-site energy

- How long is the warranty period for energy storage batteries in Ethiopia

- Energy storage batteries can be used

- How much is the wholesale price of container houses in Saint Lucia

- How does the energy storage battery container work

- How to charge for photovoltaic energy storage cabinet explosion

- What are the types of lead-acid batteries used in communication base stations

- Which batteries are used in 5g base stations

- How much does a square meter of container energy storage cost in Minsk

- How to calculate the power of liquid flow batteries for communication base stations

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.