Understanding Inverter Interchange 220V Applications and

Summary: Inverter interchange 220V refers to the ability to adapt inverters for use with 220V electrical systems across different regions or devices. This article explores its applications,

Car Inverter, 12v DC to AC Power Inverter for Car | inverter

75W car inverter for sale. The modified sine wave inverter has a peak power of 100w, input voltage of DC 12V, and output voltage AC 220V ± 10V or AC 110V ± 10v. Equipped with USB

How to Build a 12v Inverter Circuit Diagram for Powering

Find the circuit diagram for a 12v inverter and learn how it can convert direct current (DC) to alternating current (AC) for various applications. Understand the components and connections

Complete Guide to Building a DC to AC Inverter Circuit: 12V to 220V

6 days ago · A DC to AC inverter circuit transforms 12V DC input into 220V AC output, enabling you to power standard household devices from battery sources. This comprehensive guide will

How does a 12V to 220V Inverter Work?

Jun 11, 2022 · PowMr Store''s inverter converts DC power from a 12V battery system to AC power, which can power your home electrical equipment properly and can run a variety of 220V

100 watt inverter | 12v to 220v inverter | 12v to 220

100 watt inverter | 12v to 220v inverter | 12v to 220 converter | dc to ac inverter | mini inverter Is video mein humne test kiya hai 100 Watt Inverter (12V to 220V Converter) jo easily DC battery

7 Simple Inverter Circuits you can Build at Home

Are you looking to power up your home or business with reliable and efficient energy? Look no further than 220V split phase inverters. In this article, we will dive into the numerous

How to Link Two Inverters Together to Get 220V AC

Aug 19, 2025 · Most power inverters are designed to convert 12-volt, 24-volt, or 48-volt DC to 120-volt AC. These inverters are commonly used in recreation vehicles and solar power systems.

6 FAQs about [220v inverter use]

What is a simple 12V to 220V inverter?

Simple 12V to 220V inverters find widespread use in automotive applications, solar power systems, emergency backup power, and portable power solutions. Understanding load characteristics helps determine appropriate inverter specifications and ensures reliable operation.

What are the different types of power inverters?

Most power inverters are designed to convert 12-volt, 24-volt, or 48-volt DC to 120-volt AC. These inverters are commonly used in recreation vehicles and solar power systems. Special inverters can be connected together to produce 220-volts. This process is called stacking.

What is a DC to AC inverter circuit?

A DC to AC inverter circuit transforms 12V DC input into 220V AC output, enabling you to power standard household devices from battery sources. This comprehensive guide will walk you through the theory, components, design considerations, and step-by-step construction of a reliable 12V to 220V inverter circuit.

How to convert 12V DC to 220V AC?

Scientifically speaking, the transformer in an inverter must have a 1:19 turn ratio in order to convert 12V DC to 220V AC. The inverter works by switching back and forth the direction of the DC input very quickly to complete the DC to AC conversion. The result is that the 12V DC input becomes 220V AC output.

Can a 12V battery run a 220V AC?

The result is that the 12V DC input becomes 220V AC output. PowMr Store's inverter converts DC power from a 12V battery system to AC power, which can power your home electrical equipment properly and can run a variety of 220V appliances such as refrigerators, air conditioners, and televisions, etc.

Are homemade inverters safe?

There should be safety regulations regarding using homemade inverters so be sure to check before you build one. A 220V inverter circuit using 2N3055 transistors is a design that converts a low voltage DC input typically 12V to a higher voltage AC output 220V.

Update Information

- What inverter should I use to convert 36v to 220v

- How many watts does a 220v inverter use

- Costa Rica 48v to 220v inverter

- External 220v inverter

- What is the AC voltage of the inverter 220v

- Inverter 22v to 220v

- 12v to 48v inverter output 220v

- What is the use of three-phase half-bridge inverter

- How big is the 220v inverter

- Adjustable home 220v to 380v 300w inverter

- LiFePO4 12V to 220V inverter

- Can the inverter voltage be adjusted if it is less than 220v

- 220v AC voltage inverter

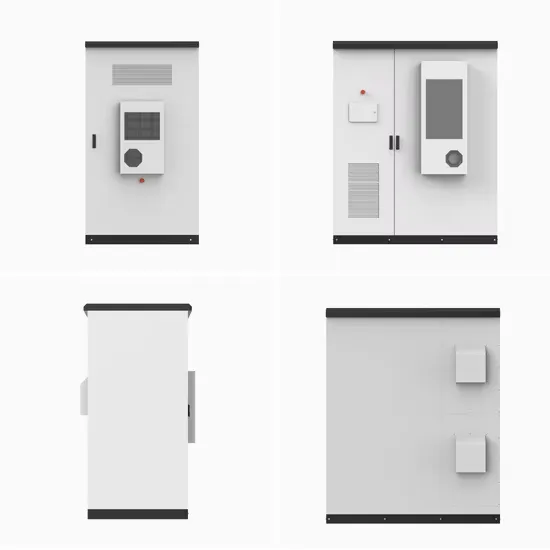

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.