Difference in initial capacity loss between single-crystal and

Aug 1, 2025 · This study investigates the pronounced initial capacity loss (ICL) in single-crystal Ni-rich cathodes compared to polycrystalline counterparts. Electrochemical and X-ray analyses

A Comparative Analysis of Mechanical and Thermal Properties in Single

Oct 19, 2024 · A Comparative Analysis of Mechanical and Thermal Properties in Single-Crystal vs Polycrystalline TiB2 19 Oct 2024 Tags: Materials Science Materials Science Materials

Single Crystalline vs Polycrystalline Materials: A

These materials are distinguished primarily by the way their atoms are arranged, which impacts their properties and applications. In this blog, we will explore the differences between single

Comparative study of polycrystalline and single

Dec 18, 2023 · Abstract This study investigates the electrochemical performance of polycrystalline and single-crystal NCM811 materials. Our findings show that

Is there a difference between single crystal and

What''''s the difference between monocrystalline and polycrystalline solar panels? Monocrystalline and polycrystalline solar panels are both made using silicon solar cells, but they differ in terms

What is the difference between single crystal and polycrystalline

The data show that the total attenuation rate of Ningbo''s single crystal photovoltaic system built in 1994 is only 3.1 % in 21 years, while the average annual attenuation rate of the single crystal

Monocrystalline vs. Polycrystalline solar panels

Jan 9, 2023 · The main difference between the two technologies is the type of silicon solar cell they use: monocrystalline solar panels have solar cells made

Difference in initial capacity loss between single-crystal and

May 4, 2025 · Despite its importance, the pronounced ICL in single-crystal Ni-rich cathodes remains underexplored, as most studies have focused on polycrystalline materials. Here, we

How to distinguish between single crystal and

Superficial differences between monocrystalline vs polycrystalline solar panels relate to the appearance of the PV modules. Monos are black and characterized by solar cells with

What is the difference between mono-crystalline

Aug 30, 2018 · The difference between mono-crystalline and polycrystalline, they both are made from silicon. Silicon extracted from a single large crystal to

Is there a difference between single crystal and

What is the difference between monocrystalline and polycrystalline solar panels? ng silicon solar cells,but they differ in terms of performance,appearance,and price. We''ve summed up the key

Monocrystalline vs. Polycrystalline Solar Panels

Oct 11, 2024 · Monocrystalline panels are known for their higher efficiency and sleek black appearance, achieved through the use of single-crystal silicon cells, while polycrystalline

What are the differences between polycrystalline and single

Jul 23, 2025 · Conclusion In conclusion, the differences between polycrystalline and single - crystal materials are significant and have a profound impact on their properties and

Introduction To Single Crystal,polycrystalline,and

Apr 7, 2024 · Polycrystalline materials, due to their simple preparation methods and low cost, are widely used in some basic material fields, such as steel manufacturing, ceramic

Polycrystalline vs. Single Crystal

Polycrystalline materials are composed of multiple small crystals with different orientations, while single crystal materials have a uniform crystal structure with no grain boundaries. Single

What is the difference between single crystal and polycrystalline

What is the difference between single crystal and polycrystalline solar panels? According to solar energy experts, the manufacturing process of single crystal and polycrystalline is different, and

Which is the winner between the single-crystalline and polycrystalline

Dec 1, 2021 · The difference of fading mechanism between single-crystal and polycrystalline materials at high temperature is discussed from aspects of both the structural evolution and

What is the Difference Between Crystalline and Polycrystalline?

Jul 9, 2025 · The main difference between crystalline and polycrystalline materials lies in their atomic structure and physical properties. Here are the key differences: Atomic Structure: In a

6 FAQs about [Is there any difference in voltage between single crystal and polycrystalline photovoltaic panels ]

What is a polycrystalline solar panel?

Polycrystalline solar panels are also made from silicon. However, instead of using a single silicon crystal, manufacturers melt many silicon fragments together to form wafers for the panel. Polycrystalline solar cells are also called "multi-crystalline" or many-crystal silicon.

Why are monocrystalline solar panels more expensive than polycrystalline solar cells?

Due to the presence of single crystal, it will absorb more solar energy and produce electricity. These types of panels are costlier because of the four-sided cutting system as compared to polycrystalline solar cells which is simpler in designing. Monocrystalline cells appear black in colour.

What is a monocrystalline solar panel?

Monocrystalline solar panels have black-colored solar cells made of a single silicon crystal and usually have a higher efficiency rating. However, these panels often come at a higher price. Polycrystalline solar panels have blue-colored cells made of multiple silicon crystals melted together.

Are polycrystalline materials better than single crystal materials?

However, polycrystalline materials are easier and cheaper to produce in large quantities, making them more commonly used in industrial applications. Single crystal materials are often used in high-tech industries such as aerospace and electronics where precise control over material properties is crucial.

Why are monocrystalline panels more efficient than polycrystalline panels?

When silicon is extracted as a single large crystal, it goes into making a mono-crystalline cell. Since the cell is composed of a single crystal, the electrons that generate a flow of electricity have more room to move. As a result, monocrystalline panels are more efficient than their polycrystalline counterparts.

What are crystalline solar panels?

These solar panels are also known as multi-crystalline or many-crystal silicon. Although these solar cells are available at an affordable price, it is less efficient compared to mono-crystalline since there is less freedom for the electrons to move. They also need a lot of space and they are usually grainy and appear like dark-blue hue.

Update Information

- What does single crystal and polycrystalline photovoltaic panels mean

- What is the current price of single crystal double glass photovoltaic panels

- Ultra-thin single crystal photovoltaic panels

- Can double-glass photovoltaic panels be made into single crystal

- What is the output voltage of a 550w single crystal photovoltaic panel

- Solar photovoltaic polycrystalline panels

- Price per watt for single crystal solar panels

- Senegal polycrystalline photovoltaic module panels

- Single crystal photovoltaic panel 780 cm wide 39 cm

- What is the difference between monocrystalline photovoltaic panels and bicrystalline panels

- What is the voltage of a single dcl photovoltaic panel

- Which photovoltaic panel is better single crystal silicon n-type or p-type

- How many watts can a single crystal silicon photovoltaic panel hold

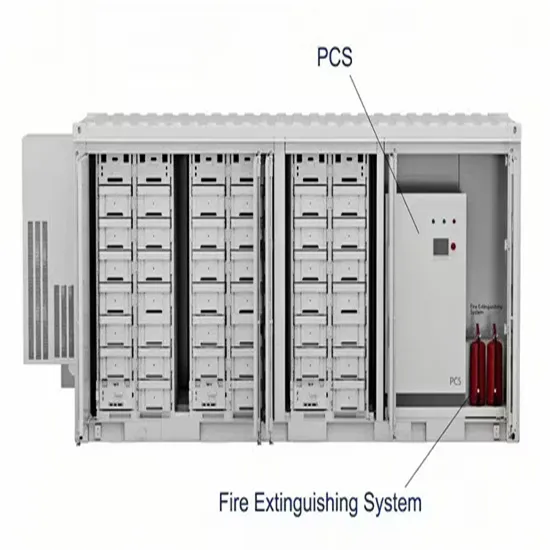

Solar Storage Container Market Growth

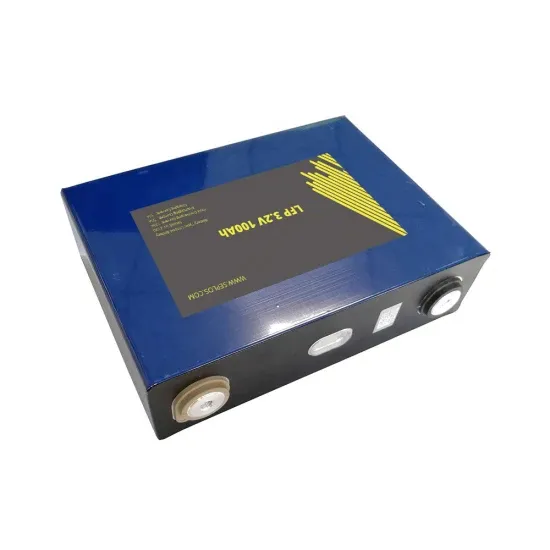

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.