Inverter went POP when supplying too much voltage, can I

Jun 1, 2024 · So I opened the inverter and see that a small capacitor has exploded. The inverter turns on with 12v but it gives a red light and won''t output any voltage. In the beginning it does

Transformer turn ratio

Nov 10, 2016 · You have already started several threads related to inverters, I wonder why the present question is so vague? You''ll first decide about an inverter topology, e.g. flyback, single

How to Wire Inverter to Battery – No Sparks, Just Power

Jul 18, 2025 · Wiring an inverter to a battery isn''t rocket science—but get it wrong, and you could fry your gear or drain your power fast. This quick guide shows you how to do it safely and

Low Battery and Overload Protection Circuit for

Dec 18, 2024 · A very simple low battery cut-off and overload protection circuit has been explained here. The figure shows a very simple circuit set up which

12 Volt inverter inside keeps shutting off and back on

May 12, 2022 · It is my 1st post and have joined because of a problem I''m having in my 1999 Gulf Stream 24'' Innsbruck trailer. The 12volt system inside the inverter keeps shutting off and then

Why do DC->AC inverters use a center-tapped primary transformer?

Mar 16, 2021 · For modern cheap 12V DC to 230V 50Hz AC inverters, it seems to be common practice to feed the 12V to a center tap on the primary side of the transformer and then use

Experiencing Inverter Trips? Discover 5 Typical

Jun 12, 2023 · Here, I''ve gathered common triggers for inverter breaker trips (usually a GFCI breaker), along with steps to detect the fault and solutions to

Turning inverter On w/ 12V signal, but capable of charging

Feb 20, 2025 · In the work truck sector, it''s very common to want an Inverter to turn on by sending a 12V signal to a terminal on the inverter that is ready and waiting for that signal. The source of

Transformer turn ratio

Nov 10, 2016 · If the input 12V is DC, it will be made into a 12V square wave and the output will be 12V*turns ratio (square wave). If you want 120VAC (RMS), you will need a peak voltage of

6 FAQs about [12v inverter turns]

Can a 12V inverter run on a 24v battery?

Verify you are connecting to a 12V battery (for 12V inverters). Connecting to a 6V or 24V battery won’t allow the inverter to run. Locate the inverter’s fuse or breaker, usually near the DC input terminals. Check if the fuse is blown or breaker is tripped and replace/reset if necessary.

How does a power inverter work?

Before diving into troubleshooting, it’s important to understand the basics of how a power inverter works. An inverter converts direct current (DC) power, like from a car battery or solar panels, into alternating current (AC) power that can be used to run standard electrical devices.

Why does my power inverter not turn on?

1. Inverter Won’t Turn On If your power inverter fails to turn on, there are a few potential causes to investigate: Ensure the DC input cables are securely connected to the battery terminals and inverter. Loose connections prevent proper current flow. Check for corroded or damaged terminals and clean or replace as needed.

Why do inverters need a power supply?

The power supply is integral to inverter operation, as it provides the necessary energy for the inverter to convert DC to AC power. Issues with the power supply can lead to a range of inverter problems, such as malfunctioning, overheating, or failure to activate.

How to choose a good inverter?

Inverters come in different sizes and wattage capacities to handle varying power loads. It’s crucial to choose an inverter that can comfortably meet the wattage requirements of the devices you need to power. Overloading the inverter by connecting appliances that draw too much power is a frequent cause of problems. 1. Inverter Won’t Turn On

What are common problems with power inverters?

Common problems with power inverters often involve issues like failure to power on, overload shutdowns, and incorrect mode settings. Inverters may not start due to a faulty power switch, dead battery, or loose wiring connections.

Update Information

- 12V Inverter Full Set

- Warsaw 48v inverter 12v to 220

- Is a 48v inverter better than a 12v one

- Afghanistan lithium battery inverter 12v to 220v

- Inverter 12v conversion efficiency

- Inverter 24v and 12v

- Inverter 12V Manufacturer

- 12V inverter voltage is low

- Solar photovoltaic inverter 12v to 220v

- New 12v inverter in Johannesburg South Africa

- Can the 12v inverter on the Internet be connected to 36v

- How big of an appliance can a 12v inverter power

- Can the inverter still convert back to 12v

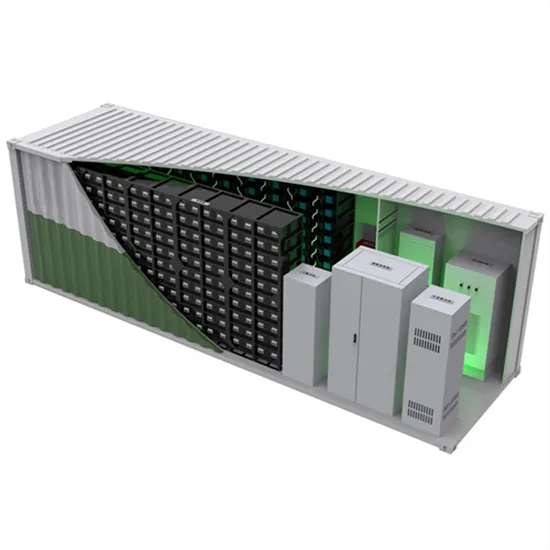

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.