UPS Battery Cabinets

Mar 5, 2025 · Versions and Model Numbers There are three distinct UPS battery cabinet versions within the ZincFive BC Series: BC 2, BC 2 - 300X, and BC 2 - 500. Each cabinet features a

BC58 Battery Cabinet Installation, Operation,

Connect main cables from the UPS or charger source to the battery cabinet output. The battery cabinet output connection point will vary depending on the cabinet configuration. The main

CENTRAL BATTERY SYSTEM: CBS

Jun 30, 2016 · CENTRAL BATTERY SYSTEM: CBS The CBS central power supply system is state-of-the-art, reliable and easy-to-operate central battery system constructed in accordance

Eaton Power Xpert 9395

Sep 7, 2024 · The 9395 battery cabinet is designed to use with the 9395, 9395P, and 9395C. The primary difference is the 9395C uses an Under Voltage Relay instead of a Shunt Trip device to

Open_Compute_Project_Battery_Cabinet_v1.0

Apr 7, 2011 · The battery cabinet is a standalone independent cabinet that provides backup power at 48VDC nominal to an Open Compute Project server triplet (custom rack, see the Open

Lithium Power Cabinets

May 11, 2020 · Interacts with a Moulded Case Circuit Breaker (MCCB) device within the cabinet to provide overall protection in the event of non-conforming operating conditions. 220V AC input

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Battery Circuit Architecture

Aug 6, 2011 · The combination of battery requirements includes: high-amplitude ESD to connector pins and exposed surfaces, coupling from an ESD event to nearby etch and components,

Galaxy Lithium-ion Battery Cabinet

Jan 2, 2025 · Read these instructions carefully and look at the equipment to become familiar with it before trying to install, operate, service or maintain it. The following safety messages may

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However,

NetSure™ 211 Series -48 VDC Battery Cabin

Jan 31, 2023 · Description or 23" relay rack or mounted to a wall. The battery cabinet contains one (1) 40 A battery disconnect circuit breaker and provides alarm leads a in Figure 2.5 to

ZincFive BC 2 Series UPS Battery Cabinet Data Sheet,

Mar 5, 2025 · The Power of Good ChemistryTM Superior Power Density – Approximately twice the power of lithium-ion systems, and half the linear width Low Total Cost of Ownership – Low

Lithium Power Cabinets

May 11, 2020 · LIBM composition Communications Fan power Example configuration DC 24V DC input Internally fused socket supplies power directly to LIBM circuits Single string controller -

NICKEL-ZINC BC 2 UPS Battery Cabinets

Nov 14, 2023 · The Power of Good ChemistryTM Superior Power Density – Approximately twice the power of lithium-ion systems, and half the linear width. Low Total Cost of Ownership – Low

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · The option provides functional access to the equipment circuit breaker via a handle located on the exterior of a cabinet door that is physically connected to the circuit breaker in

Eaton 93PM Integrated Battery Cabinet-Small Welded

Mar 29, 2025 · The 432Vdc version contains a single string of 36 batteries and the 480Vdc version contains a single string of 40 batteries. Removable battery trays with quick

How to design cost-sensitive battery-monitoring

Jul 15, 2016 · Figure 3 shows a high-side battery-current-sensing circuit using the TLV369, which features a rail-to-rail input stage with >100dB of CMRR over

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

VRLA battery cabinets

Mar 24, 2025 · that can cause risks of electric shock and short circuit (fire). • Designed according to the specific UPS model for easy connections, correct recharge current and appropriate

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Lithium Ion Battery Cabinet Solution

Jul 8, 2020 · The battery solution shall consist of front-access battery cabinets, monitored lithium-ion battery modules, switch gear with embedded management, and a switched mode power

ATESS DC Cabinet-280R Datasheet--20240515

Jun 4, 2024 · The DC cabinet is mainly to aggregate and share the current distribution of each battery rack to achieve the charge and discharge management function of each battery rack.

6 FAQs about [5-string battery cabinet power display circuit]

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

How important is battery-circuit design & layout?

Battery-circuit design and layout are consid-erably more critical than might be expected.

How do PCB layout and connection drops affect voltage measurements?

Voltage measurements of the battery stack are also affected by PCB layout and connection drops. Some battery-pack designs may use nickel straps from the PCB connection to the battery stack. Nickel is used because it is easy to weld to the battery cells, but its resistance is five times as much as that of copper.

Why is a single string battery set-up important?

A single weak or bad cell can exponentially lower the capacity of the entire battery pack. A properly engineered system can improve the overall reliability, but only when additional equipment and significant engineering time is invested. Whenever possible, a single string set-up should be considered.

Can a PCB measure a true cell voltage?

When current flows through these straps, the voltage measured by the circuitry on the PCB connected to these straps will not measure the true cell voltage. To measure the true cell voltage, separate voltage measurement connections should be made with wiring that does not carry the load current.

How do you pull up a battery pack VCC?

The electrical path to pull up the battery pack VCC passes through the host capacitance from Pack+ to Pack–, through a substrate diode in the host interface driver from VSS to the commu-nication or interface line, and through a substrate diode from this line to VCC in the battery-pack circuitry. The complete path is shown in Fig. 6.

Update Information

- How to use ESS power base station in battery cabinet display cabinet

- UPS uninterruptible power supply host and battery cabinet size

- Budapest liquid-cooled energy storage battery cabinet communication power supply

- How to connect the bridge to the battery cabinet ESS power base station

- Battery cabinet production line base station power generation requirements

- Lithium battery station cabinet production station power supply

- Outdoor power battery cabinet cabinet

- Uninterruptible power supply battery cabinet function

- What is the power capacity of the battery cabinet

- Equipment room battery cabinet ESS power base station

- Price of battery cabinet in communication power supply factory

- New Energy Battery Cabinet Communication Power Protocol

- What is the power of the new energy battery cabinet

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

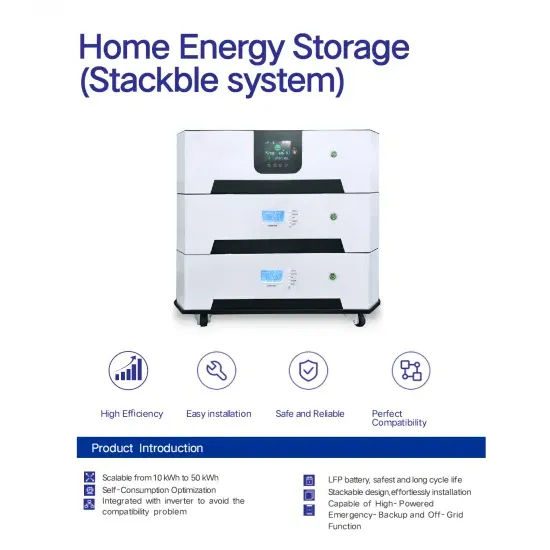

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.