Understanding the Cost of Flywheel Energy Storage Systems:

Jun 16, 2019 · Let''s pop the trunk on flywheel costs: Material Costs: That fancy carbon-fiber rotor? About 40% of the total bill. Recent data from the U.S. Department of Energy shows

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · ABSTRACT The rapid growth of renewable energy sources like photovoltaic solar and wind generation is driving the need for cost-effective energy storage to capture energy

Flywheel Energy Storage Cost per kWh: Efficiency Meets

Current flywheel energy storage costs vary by application: Singapore''s hybrid solar-flywheel microgrid achieved 94% round-trip efficiency at $1,620/kWh - 18% cheaper than equivalent

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electrical power system into one that is fully sustainable yet low

A review of flywheel energy storage rotor materials and

Dec 25, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Flywheel vs Battery Energy Storage Cost Analysis

Apr 14, 2025 · What is the typical cost range for flywheel energy storage systems compared to battery-based systems? How does the rotational speed of a flywheel affect its efficiency versus

Flywheel Energy Storage Costs: Breaking Down the

Current flywheel installations average $1,100-$1,500 per kW compared to $700-$900/kW for lithium batteries [1] [10]. However, when considering total lifecycle value, the picture changes

The development of a techno-economic model for the

Oct 1, 2021 · Two rotor configurations were considered: composite rotor flywheel and steel rotor flywheel. The total investment costs of the composite rotor and steel rotor flywheel storage

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Aug 27, 2024 · Cost-Benefit Analysis of Flywheel Energy Storage Flywheel energy storage (FES) is a promising technology that has gained significant attention in recent years due to its

Flywheel vs Battery Energy Storage Cost Analysis

Apr 14, 2025 · Cost and Lifecycle Cost Comparison: This comparison simplifies the complexities of energy storage system economics. Actual costs and lifespans can vary significantly based

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

RotorVault Energy Storage Cost Analysis and Flywheel Price

5 days ago · Compared to other technologies like supercapacitors and legacy flywheels, RotorVault has much lower CAPEX and better storage capacity. Explore RotorVault''s cost

A Comprehensive Review on Flywheel Energy Storage

Aug 2, 2023 · Finding efficient and satisfactory energy storage systems (ESSs) is one of the main concerns in the industry. Flywheel energy storage system (FESS) is one of the most

Flywheel Energy Storage Costs and Profits: A Spin-Worthy

Nov 7, 2023 · The Price Tag of Spinning Energy Let''s cut through the marketing spin. A typical 100kW flywheel system costs between $1,500-$3,000 per kW installed. But wait – before you

Understanding the Cost of Flywheel Energy Storage Systems:

Jun 16, 2019 · Why Flywheel Energy Storage Is Making Headlines (and Headaches) Let''s face it – when someone says "energy storage," your brain probably jumps to lithium-ion batteries faster

Flywheel Energy Storage Cost per kWh: Efficiency Meets

Why Flywheel Storage is Redefining Energy Economics As global industries seek cost-effective energy storage, flywheel systems emerge as game-changers with flywheel energy storage

Flywheel Energy Storage: Alternative to Battery

Oct 5, 2024 · As the energy grid evolves, storage solutions that can efficiently balance the generation and demand of renewable energy sources are critical.

Residential Flywheel Energy Storage: Revolutionizing Home Energy

As renewable energy adoption surges globally, homeowners face a critical challenge: energy storage that''s reliable, efficient, and sustainable. Enter residential flywheel energy storage—a

Cost-Benefit Analysis of Flywheel Energy Storage in context of flywheel

Aug 27, 2024 · Flywheel energy storage (FES) is a promising technology that has gained significant attention in recent years due to its potential to mitigate the intermittency of

Flywheel Energy Storage Cost Performance: Why This Tech is

Dec 27, 2023 · Flywheel energy storage cost performance hinges on three factors: Material Science: Carbon fiber vs. steel rotors? The former costs 3x more but lasts 10x longer. Math

6 FAQs about [Flywheel energy storage energy cost]

What is a flywheel energy storage system?

A typical flywheel energy storage system , which includes a flywheel/rotor, an electric machine, bearings, and power electronics. Fig. 3. The Beacon Power Flywheel , which includes a composite rotor and an electric machine, is designed for frequency regulation.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel-based hybrid energy storage systems based on compressed air energy storage?

While many papers compare different ESS technologies, only a few research , studies design and control flywheel-based hybrid energy storage systems. Recently, Zhang et al. present a hybrid energy storage system based on compressed air energy storage and FESS.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

How do you calculate the energy capacity of a flywheel?

The following equations describe the energy capacity of a flywheel: (2) E m = α ′ α ′ ′ α ′ ′ ′ K σ / ρ (3) E v = α ′ α ′ ′ α ′ ′ ′ K σ where α ′ is the safety factor, α ′ ′ the depth of discharge factor, α ′ ′ ′ the ratio of rotating mass to the total system mass, σ the material’s tensile strength, K the shape factor, and ρ the density.

What are flywheel systems used for?

Almost all the existing flywheel systems are designed for specific applications such as frequency regulation or UPS. They require specialized knowledge and techniques for manufacture, assembly, and maintenance, which prevents them from being produced in large quantities to reduce cost per unit.

Update Information

- How much does a micro flywheel energy storage battery cost

- Flywheel system energy storage device composition

- Energy storage project cost structure

- Cost of building industrial and commercial energy storage

- Electricity cost of electrochemical energy storage system

- How much does a large flat solar energy storage device cost

- How much does a 2000 kWh energy storage container cost

- Manama local energy storage battery cost performance

- Ratio of production cost of energy storage cabinet

- How much does it cost to invest one watt in photovoltaic energy storage

- Approximate cost of Bin energy storage container

- Cost of energy storage power station

- The cost of purchasing energy storage for photovoltaic power stations

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

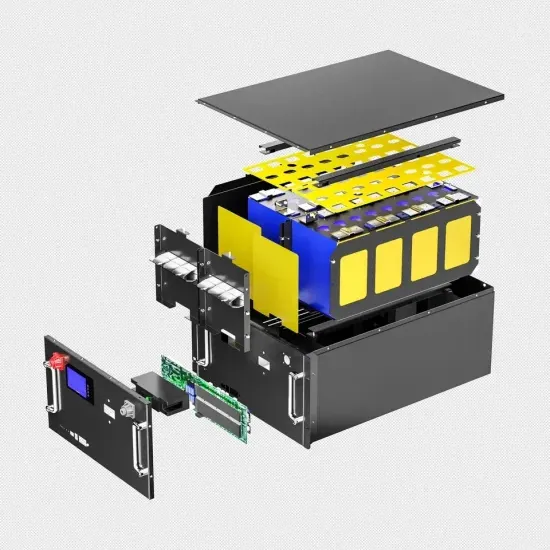

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.