Base Station Installation & Maintenance

To ensure stable communication between a base station and connect with the stability of mobile devices, it is necessary to check radio communication performance and eliminate radio wave

Principles of Retrofitting Wireless Base Station Towers

Mar 30, 2025 · The rapid evolution of wireless communication technologies, such as 5G and beyond, has necessitated the retrofitting of existing base station towers to meet new

Maintenance of communication tower

It is like a silently dedicated giant, supporting a vast communication network and providing critical support for signal transmission and reception. The normal operation of communication towers

Energy storage system of communication base station

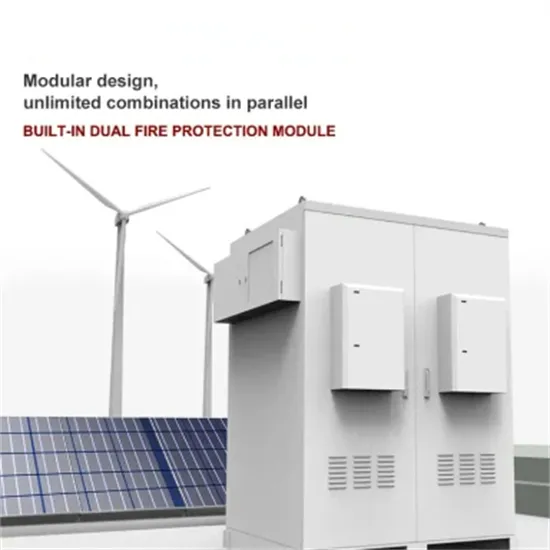

Energy storage system of communication base station Base station energy cabinet: floor-standing, used in communication base stations, smart cities, smart transportation, power

The Professional Guide to Tower Maintenance

We offer expert services for the Maintenance of Communication Towers, ensuring structural stability, signal clarity, and safety compliance. Our services include tower painting, bolt

Predictive maintenance of base transceiver station

Nov 1, 2023 · The XGBoost algorithm was employed to develop a predictive model for the maintenance of Base Transceiver Station power failure. By using Machine Learning

Understanding Base Transceiver Stations: The Backbone of

Jan 1, 2025 · Simply put, a base transceiver station (BTS) is a vital component of mobile networks, serving as the communication hub that connects your mobile phone to the wider

CHAPTER 10 OPERATION AND MAINTENANCE

May 9, 2004 · National Communication Policy prepared by the MOI encourages private participation to non-core telecommunication activities, such as external plant construction, and

Cooling for Mobile Base Stations and Cell Towers

May 5, 2025 · Application Overview Bulky compressor-based air conditioners have traditionally been used for removing heat generated by communications equipment installed in base

Telecom Tower Maintenance Best Practices

Apr 7, 2024 · Telecom tower maintenance is crucial for ensuring uninterrupted communication services and the overall integrity of the tower infrastructure. Regular inspections and

Communication Base Station Maintenance Guide | We

Did you know a single communication base station failure can disrupt services for 5,000+ users? As global 5G deployments accelerate – with over 7 million base stations projected by 2025 –

Communication base station repair procedures | We

Communication Base Station Corrosion Resistance When was the last time you noticed discoloration on a communication base station? With over 7 million towers globally requiring

How to Maintain Backup Power Supply for Telecommunications Base Stations?

Inverter Maintenance: Inspect inverters regularly for any signs of damage or malfunction. Clean air vents to prevent overheating, check electrical connections for tightness, and perform firmware

Communication Base Station Backup Power Selection Guide

Why Backup Power Systems Are the Lifeline of Modern Telecom Networks? When a typhoon knocks out grid power across Southeast Asia, how do operators ensure communication base

Empowering telecommunication towers employing

Mar 13, 2025 · In the field of telecommunication towers, specifically focusing on Base Transceiver Station (BTS) units, this research presents a revolutionary power supply system that is

Post-earthquake functional state assessment of communication base

Dec 1, 2024 · There is a lack of models that can fully evaluate the post-earthquake functional states of base stations with the consideration of the dependencies between different

Communication Base Station Phase Balancing | We Group

Why Phase Balancing Determines 5G Network Survival When 25% of mobile network outages stem from phase imbalance, shouldn''t we ask: How does communication base station phase

6 FAQs about [Communication base station inverter signal tower maintenance]

How to maintain a telecom tower?

Common challenges include the need for frequent cleaning to remove debris and prevent signal interference. Best practices for tower maintenance include regular inspections, detailed record-keeping, predictive and preventive maintenance approaches, and cost-effective strategies. What Are the Requirements for Telecom Tower?

How can preventive maintenance improve a tower's service life?

Implementing preventive maintenance strategies, such as regular inspections, repairs, and comprehensive record-keeping, can prevent equipment failures and extend the tower's service life.

Why is Telecom Tower maintenance important?

Telecom tower maintenance is crucial for ensuring uninterrupted communication services and the overall integrity of the tower infrastructure. Regular inspections and preventive maintenance are key best practices that help identify potential structural weaknesses, prevent equipment failure, and address environmental hazards.

What are the different types of Telecom Tower maintenance?

Different tower types, including lattice, guyed, monopole, camouflage, and mobile towers, have varied maintenance requirements. Implementing a preventive maintenance strategy through regular inspections and repairs helps prevent problems and component failures, ultimately extending the usable lifetime of telecom equipment.

How do Telecom Tower owners prevent equipment failures?

Preventive maintenance strategies, including regular inspections and repairs, play a crucial role in identifying potential issues and preventing equipment failures. By conducting regular upkeep and accounting for weather conditions, telecom tower owners can maintain a robust and reliable infrastructure.

What are the components of a telecom tower?

Key components that enable the smooth operation of a telecom tower include various communications equipment, energy management assets, and supplementary power sources. These components play a crucial role in ensuring reliable and uninterrupted communication services. Communications equipment is at the heart of a telecom tower.

Update Information

- Communication base station inverter grid-connected signal tower power supply

- Communication signal tower base station outdoor

- San Marino communication base station inverter grid connection maintenance

- Communication base station inverter tower design

- Chisinau Communication 5g signal tower base station construction

- Abu Dhabi communication base station inverter grid-connected operation and maintenance

- Budapest communication base station inverter grid-connected maintenance energy storage

- Communication base station uninterruptible power supply signal tower splicing method

- Taipei communication base station inverter grid-connected photovoltaic power generation maintenance solution

- Communication base station inverter grid-connected energy-saving installation solution

- Communication base station inverter battery detection unit

- New Technology for Inverter of Communication Base Station

- Does the inverter of the communication base station need to be shared by operators when connected to the grid

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.