Technical data sheet Double-sided glass microlens arrays

Jan 16, 2024 · Double-sided glass microlens arrays Variable microlens arrays Microlens arrays for very different applications offer great potential for future developments by enabling

Polishing uniformity analysis and process optimization

Jun 1, 2023 · The double-sided polishing technique is suitable for the rough polishing of flat optical components [3]. The ring pendulum double-sided polishing technology is used in this study as

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Defects in double-sided incremental forming of woven fabric

Aug 1, 2025 · In double-sided incremental forming of woven prepregs, the multi-layer layup, i.e. dummy sheets positioned above and below the prepreg layer, poses challenges for the in-situ

Maskless lithography based on digital micromirror device

May 1, 2019 · A new type of maskless lithography system based on digital mirror device (DMD) is proposed, constructed, and experimentally demonstrated. It includes a pin-hole array

Robust optimization of double-sided LCC compensation

Mar 23, 2024 · A compensatory topology parameter optimization method of double-sided LCC based on NSGAII algorithm is proposed, which effectively reduces the system output power

Mastering Double Sided PCBs: A Comprehensive Guide to

Jan 2, 2024 · Dive into the world of double sided PCBs and discover the core principles of designing and implementing this essential electronic cogwheel. Our practical approach

How Double-Sided Polishing Can Revolutionize Optical

Aug 17, 2025 · Precision Glass & Optics integrated a PR Hoffman double-sided polisher (DSP) into the production lineup. Transformed ability to manufacture optical components.

Effects of polishing parameters on surface quality in sapphire double

Jun 15, 2020 · Abstract To reveal the influence of polishing process parameters on the surface quality of sapphire after double-sided chemical mechanical polishing (CMP), the orthogonal

What is the structure of a double-sided double-glass n-type

First, the core part of the double-sided double-glass n-type monocrystalline solar photovoltaic module is the N-type monocrystalline silicon cell. This cell is made of high-purity N-type

Single Sided vs Double Sided vs Multilayer PCBs – RF PCB

Aug 29, 2024 · What is a Double Sided PCB? A double sided PCB has conductive copper traces on both sides of the insulating substrate. Components can be mounted on either or both sides

Performance of ventilated double-sided PV façade

Jan 1, 2013 · Thermal performance comparison of double-sided PV façade with that of conventional clear glass façade was made through outdoor monitoring. Natural convective

In-Depth Analysis of Double-Sided PCB Engineering

Apr 7, 2025 · Modern double-sided PCBs employ dynamic lamination processes. Taking Isola 370HR material as an example, its glass fabric uses 1080-style weave with warp/weft density

A new fabrication process of TGV substrate with silicon

Dec 1, 2005 · Using this modelling procedure, the cell temperature is estimated with a root mean square error of 1.3 °C. 1. Introduction. It is well known that most of the solar radiation absorbed

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Double sided double glass half sheet multi main grid 78

Product Details Double sided double glass half sheet multi main grid 78 piece string 158.75mm square single-crystal solar cell high-efficiency 440W-460W photovoltaic module Home Product

Design of a Double-Sided Non-Displacement Telecentric

May 26, 2025 · A double-sided telecentric zoom optical system can ensure the measurement and detection accuracy for different workpiece sizes and plays a crucial role in industrial detection.

Double-Sided Copper Filling of Small Diameter, High-Aspect

Apr 2, 2025 · Glass substrates offer significant advantages over current organic substrate, particularly in high-density, high-performance chip packaging for data-intensive applications

A Quantitative Comparison Between Double Glass

Jul 27, 2017 · The use of half-size silicon (Si) wafer solar cells in photovoltaic (PV) modules can enhance the output power compared to full-size Si wafer solar cells. In this paper, an optimal

6 FAQs about [Double-sided double-glass component parameters]

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is the electrical performance of BYD double-glass modules?

The electrical performance of the BYD double-glass modules was as expected for multicrystalline cells, with power bins ranging from 245W to 265W for 60-cell modules, and from 295W to 315W for 72-cell modules. The modules were subjected to numerous accelerated ageing tests.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is double sided glass reflow process?

In the double sided glass reflow process, the bonded wafer stack is heated inside an atmospheric furnace at a temperature above the Pyrex 7740 glass transition temperature of 525 °C, thus, the viscosity of the glass is drastically lowered, and the glass becomes soft.

How can double sided glass reduce reflow treatment time?

In order to reduce reflow treatment time and ensure the cavity is filled with glass, double sided glass in silicon reflow process is proposed in this paper. In this process, different parameters of time and treatment temperatures are taken as needed. Then surface characteristic and reliability test results through tension test are present.

Can double sided glass be used in Silicon reflow process?

By using double sided glass in silicon reflow process with a patterned silicon mold, a thick and robust TGV substrate which is difficult or timewasting to realize by single side glass reflow process could be achieved. The fabrication process and parameters are studied in details.

Update Information

- Lifespan of double-sided double-glass modules

- Double-sided double-glass module installation

- Parameters of 170W double-glass monocrystalline module

- When did the double-sided double-glass components appear

- EK 280 energy storage battery parameters in Krakow Poland

- Vilnius Communication Green Base Station Photovoltaic Power Generation Parameters

- Riyadh Communication Green Base Station Photovoltaic Power Generation Parameters

- Huawei energy storage system scale parameters

- Base station energy storage control parameters

- What parameters should be considered for outdoor power supply

- Outdoor power battery parameters

- How to view the recommended parameters of base station power supply

- Highest parameters of photovoltaic inverter

Solar Storage Container Market Growth

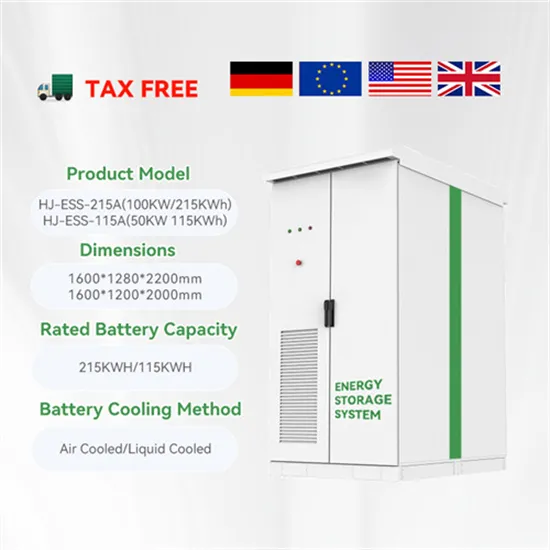

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.