Solar anti-reverse current grid-connected inverter

4 Ways of reverse power flow protection in grid-connected By incorporating anti-reverse current functionality, PV system operators can ensure safe and efficient operation, eliminate reverse

Filter Board in Grid-Connected Inverters Key Functions and

Anti-Reverse-Current Grid-Connected Photovoltaic Inverter Key Features and Industry Applications Solar Power Directly Connected to Battery or Inverter Key Considerations for

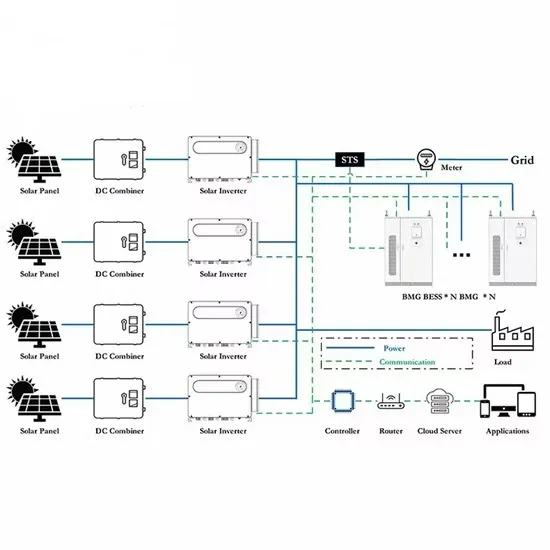

Grid-connected inverter anti-reverse flow energy storage

Anti-reverse current working principle: Install an anti-reverse current meter or current sensor at the grid connection point. When it detects a current flow to the grid, it sends a signal to the

Photovoltaic inverter anti-reverse discharge

Is a photovoltaic grid connected system an anti-reverse current generation system? The power grid company requires the photovoltaic grid-connected system to be built later to be an anti

Converting Grid-Connected PV Inverters to Off-Grid Systems

Grid-Connected Energy Storage Photovoltaic Power Generation Systems The Future of Renewable Integration Construction Plan for Container Energy Storage Power Station

Anti-Reverse Current 】 SPD-CT 800W Solar Micro Inverter Smart Grid

Anti-backflow On Grid Micro Inverter Solar 800W SPD-CT 800W Protection level up to IP67,10 years warranty SPD-CT Series micro inverter is the second generation of SP micro inverter,

Anti-Reverse-Current Grid-Connected Photovoltaic Inverter

Anti-reverse-current grid-connected photovoltaic (PV) inverters are revolutionizing solar energy systems by preventing power backflow to solar panels during low-demand periods. This

how to store energy with anti-reverse current grid-connected inverter

A new Inverter Side Output Current Control Method for Grid-connected Inverter This paper proposes a new control method for a grid-connected inverter with a small LCL filter without

Solar anti-reverse current grid-connected inverter

Solar anti-reverse current grid-connected inverter 4 Ways of reverse power flow protection in grid-connected By incorporating anti-reverse current functionality, PV system operators can ensure

Anti-reverse current photovoltaic solar grid-connected inverter

Its compatibility with ''Micro Grid-tie Inverter'' technology ensures efficient energy distribution and management within small-scale power grids. This product is proudly made in China, Fujian

What is a anti-backflow? How to anti-backflow?

Aug 4, 2023 · 4. The solution? Deye inverter anti-backflow working principle: install an meter with CT or current sensor at the grid-connected point. When it detects that there is current flowing

Solar power generation anti-reverse current diode

Application of Anti-Reverse Circuit in Solar System Since the inverter has an anti-reverse connection circuit, the anti-reverse diode in the circuit should be short-circuited with a copper

Photovoltaic anti-reverse current inverter installation

Anti-Reverse Power Controller for Three Phase Operation Principle: o ARPC will detect grid voltage on R,Y,B input and current on CT, the CT are connected before the local load input. o

Photovoltaic inverter anti-reverse flow principle

Inverters with transformers of conventional type, connected in PV grid-tied generation systems have now being replaced by transformerless inverters due to various reasons such as

Ankerui Energy Storage Inverter Anti-Reverse Flow Detection

In the grid-connected power generation system, since the external environment is constantly changing, in order to prevent the photovoltaic grid-connected system from generating

Principle And Solution Of Anti Backflow For Photovoltaic

Dec 11, 2024 · The AC output terminal of the inverter is directly connected to the meter and then connected to the grid connection point to achieve anti backflow; For high-power grid

Principle and implementation of photovoltaic inverter anti-reverse

An anti-backflow meter + CT mutual inductor is installed on the main line on the household incoming line side to collect the real-time power, current size and direction on the busbar.

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The requirements for the grid-connected inverter include; low total harmonic distortion of the currents injected into the grid, maximum power point tracking, high efficiency,

1000w Cross-border Anti-reverse Current Grid-connected

The working principle of the anti-reverse inverter is to control the reverse current phenomenon by adopting a specific circuit design, monitoring the inverter output current in real time, and

Principle of Photovoltaic Anti-Reverse Current Inverter

In this review, the global status of the PV market, classification of the PV system, configurations of the grid-connected PV inverter, classification of various inverter

What Is the Reverse Flow Protection of Photovoltaic Inverters?

Reverse flow protection is vital for the operation of grid-connected solar systems. Let''s dive deeper into its mechanisms and importance.Reverse flow protection prevents the reverse flow

Photovoltaic inverter and anti-reverse flow device

In this paper, a protection scheme against reverse power flow concerning PV integrated grid system are being discussed. This paper aims to explore recourses to modify the existing

How to Control Output Current in Three-Phase Grid-Connected

Grid-connected three-phase inverters are the backbone of modern renewable energy systems, enabling efficient power conversion between DC sources like solar panels and the AC grid.

Anti-reverse current inverter solar power generation

A solar inverter feeds power back to the grid by converting the DC current generated by the solar panels into AC current that is synchronized with the grid''''s voltage and frequency. This allows

Photovoltaic inverter anti-backflow installation

Upon detecting current flow towards the grid,the inverter will reduce its output power until the countercurrent is eliminated,thereby achieving anti-backflow. It is important to note that the CT

Anti-reverse charging function of photovoltaic inverter

Is a photovoltaic grid connected system an anti-reverse current generation system? later to be an anti-r verse current generation system. Wh t is anti-backflow? What is

Principle and implementation of photovoltaic inverter anti-reverse

When it is detected that there is current flowing to the grid (reverse current), the anti-backflow meter transmits the reverse power data to the inverter through RS485 communication.

6 FAQs about [EK Anti-reverse current grid-connected inverter]

How do solar inverters work?

For example, solar controllers such as grid-connected inverters, off-grid inverters and pumping inverters will connect electrolytic capacitors in parallel on the DC input side to support the DC voltage.

What happens if solar power input is reversed?

If the solar power input is reversed, the power will form a short circuit through the anti-parallel diode. According to the characteristics of the solar module, the voltage of the solar power supply When pulled down, the voltage value is only the sum of the forward voltage drop of the two diodes, which will not damage the electrolytic capacitor.

What is an anti-reverse connection circuit?

Therefore, the solar system related equipment is generally designed with anti-reverse connection circuits to ensure that the solar equipment is protected from damage when the input power is reversed. The simplest anti-reverse circuit is to connect a diode in series with the input circuit, as shown in Figure 1.

What is the simplest anti-reverse circuit?

The simplest anti-reverse circuit is to connect a diode in series with the input circuit, as shown in Figure 1. In applications with lower input voltage, Schottky diodes can be used to reduce the loss due to tube voltage drop. Improve the working efficiency of the whole machine.

Which pb2200l pumping inverter was used for reverse connection test?

The PB2200L pumping inverter produced by Shenzhen Solartech Company was used for reverse connection test. Since the inverter has an anti-reverse connection circuit, the anti-reverse diode in the circuit should be short-circuited with a copper wire.

How MOSFET can be used in anti-reverse circuit?

Improve the working efficiency of the whole machine. In order to further reduce the loss caused by the voltage drop of the diode, MOSFET can be used as the switching device in the anti-reverse circuit. As shown in Figure 2, select a MOSFET with a small turn-on voltage drop.

Update Information

- What is an anti-reverse current grid-connected inverter

- Inverter adjusts grid-connected current

- Grid-connected inverter current direction

- Grid-connected inverter current penetration

- Energy storage inverter grid-connected discharge

- Inverter current DC component standard

- Vienna communication base station inverter grid-connected rescue

- Grid-connected inverter and several solar panels

- China-Africa grid-connected inverter manufacturers

- Aesthetic design scheme for grid-connected inverter of communication base station

- 48v1000w inverter working current

- Photovoltaic grid-connected inverter research and development

- India 5G communication base station inverter grid-connected construction project planning

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.