SAM Photovoltaic Models

2 days ago · The detailed photovoltaic model calculates a grid-connected photovoltaic system''s electrical output using separate module and inverter models. It requires module and inverter

Inverter Matching for Trina Solar''s Vertex Series

Dec 24, 2021 · As of June 2021, mainstream inverter suppliers around the world have launched high-current inverters that match the 210 modules. The current of the single-channel maximum

Solar System Components | SpringerLink

Oct 4, 2021 · This chapter describes the building blocks of a solar photovoltaic system in detail. The chapter begins with an overview of solar photovoltaic modules and the relevant

Best Solar Inverters in India | Top Brands and

Aug 9, 2025 · Moreover, string inverters are up to 90% cheaper than micro-inverters; hence, they''re the best when it comes to rooftop solar installations at

Optimized current and voltage matching in high-efficiency bifacial

May 1, 2025 · This experiment utilizes a mechanical stacking tandem solar cell to achieve voltage and current matching between a III-V top cell and TOPCon bottom cells, a critical step toward

How to Match Photovoltaic Inverters with Solar Panels: A

Meta Description: Discover step-by-step strategies to correctly size and pair photovoltaic inverters with solar panels. Learn about voltage ratios, power thresholds, and AI-driven matching tools –

What are the bifacial photovoltaic components

Bifacial photovoltaic cell and module technologies are rapidly increasing their market shares. The International Technology Roadmap for Photovoltaic (ITRPV) 2019 Results notes that as of

How to match photovoltaic panels with batteries for

A well-made connection between your solar panels, inverter, and batteries offers several advantages for your solar energy system: Maximizes electricity generation by efficiently

International Journal of Applied Power Engineering (IJAPE)

Nevertheless, inverter is reported as the critical component in the photovoltaic (PV) system. Hence this work presents reliability-oriented performance evaluation of PV inverter with bifacial

The Most Efficient and Adaptable Solution Design for

May 21, 2024 · The Huawei string inverter configured with multi MPPTs is the best match for bifacial modules, and also the main technical solution for lowering levelized cost of energy

Bifacial Solar Panels: Electrical Design Considerations and

Feb 21, 2025 · Bifacial solar panels have emerged as a game-changer in photovoltaic (PV) technology, offering higher energy yield by capturing sunlight on both the front and rear sides

A comprehensive review and outlook of bifacial photovoltaic

Nov 1, 2020 · Bifacial photovoltaic (bPV) technology is regarded as a promising alternative, as it can generate more power than conventional mono-facial PV (mPV) technology by absorbing

Accurately "matching" and "enabling" N-type bifacial

From the analysis of the recent third batch of leaders'' winning bids, the application of bifacial modules is increasing. Inverters are the core equipment for increasing the power generation of

IQ Microinverter compatibility calculator | Enphase

2 days ago · Enphase IQ Microinverters are compatible with bifacial PV modules if the temperature-adjusted electrical parameters (maximum power, voltage, and current) of the

Bifacial PV Module Installation Manual

Jan 12, 2022 · 2.4.1 Installation of bifacial module without shading the back of module When designing the modules'' support structure, the support components cannot cross the module

Reliability Oriented Performance Evaluation of PV Inverter

Jan 16, 2025 · Nevertheless, inverter is reported as the critical component in the photovoltaic (PV) system. Hence this work presents reliability-oriented performance evaluation of PV inverter

Solar Panels: Monofacial vs. Bifacial

Aug 15, 2025 · Solar Panels: Monofacial vs. Bifacial - A Comparative Insight into Photovoltaic Modules Choosing the right solar panel technology can make or break your solar project''s

Unixun Inverter

Sep 18, 2023 · Photovoltaic inverter and component parameter interpretation and ratio analysis In the photovoltaic system, photovoltaic modules and inverters are the two most important parts.

Jinko Solar Whitepaper on Swan Bifacial

Dec 17, 2019 · As a result, it is very important to identify the estimated bifacial gain before selecting the electrical components (inverters, cables, protection

Bif a cial Design guiDe

Jan 30, 2020 · When there is a certain amount of bifacial gain, the electrical behavior of bifacial PV module is almost equivalent as that of a monofacial with higher output power, which from

Components of a Solar Panel: Complete Technical Guide

1 day ago · Understanding the components of a solar panel empowers informed decision-making when selecting photovoltaic systems. Each component—from photovoltaic cells and protective

Photovoltaic power station matching inverter

What is inverter matching for Trina Solar''s vertex series photovoltaic modules? Trina Solar''s inverter matchingfor the Vertex Series photovolvoltaic modules is discussed in the White

Solar inverter components + introduction and

Jul 27, 2025 · What is a Solar Inverter? A solar inverter is an electronic unit that converts DC energgenerated by solar panels into AC, which is the standard

Bifacial inverter: Make your home''s bifacial components

It is also worth noting that due to the increase in the power generation of bifacial components and the tracking system extending the inverter''s high-power operation period, the inverter is in full

Next generation inverters optimize bifacial boost

Jun 6, 2019 · Designing inverters for bifacial modules that are capable of managing a large and varying yield gain is a first basic task. If inverters are not

Current Matching in Bifacial GaAs/Si Tandem Cells

Jun 25, 2021 · We show that the efficiency of a suitably designed two-terminal GaAs/Si tandem PV cell is insensitive to current matching and therefore well suited for bifacial

Design Guide for Bifacial Solar Modules

Jul 22, 2017 · ails. Summary of the Major Differences: Electrical calculations such as string and wire sizing, inverter inputs, and overcurrent protection devices should be based on the

6 FAQs about [Photovoltaic inverter bifacial component matching]

How to choose an inverter for bifacial PV module?

sizingInverter sizingTwo factors should be considered when choosing an inverter for of the Inverter The current (Isc) value of the Bifacial PV Module is increased by backside boost, where the voltage of t e bifacial is constant. As a result, the current increases around 20% when the

What is bifacial PV module?

of the bifacial module.When there is a certain amount of bifacial gain, the electrical behavior of bifacial PV module is almost equivalent as that of a monofacial with higher output power, which from the sum of the irradiance exposed to the front and the backside nder sum of irradiance)3-1. Electrical Design fo

How bifacial PV module is calculated?

ackside simultaneously. As a result, the total produced energy of the Bifacial PV Module is calculated by the sum of energy from the frontside and the backside of the module. The bifacial output power can be viewed as a monofacial module producing energy from the total sum of sunlight exposed to the frontside and the backside

What is the design guide for bifacial solar modules?

Design Guide for Bifacial Solar ModulesThis Design Guide was created to aid in the understanding and opt ization of Prism Solar’s PV modules. This document should be used as a supplement for individuals and system designers who are sk

Are bifacial solar inverter makers getting better performance?

Inverter makers are under pressure to upgrade performance to accurately measure and manage the boost from bifacial solar panels.

Are bifacial inverters redesigned?

Inverter improvements including greater granularity of maximum power point tracking (MPPT), the marriage of artificial intelligence with more capable algorithms, and string overload safety are ushering in the next generation of inverters redesigned for bifacial systems, according to the development team at Huawei Technologies’ Smart PV Business.

Update Information

- Photovoltaic solar water pump inverter

- Bidirectional photovoltaic energy storage inverter

- Lima Photovoltaic Energy Storage Inverter Manufacturer

- Inverter Distributed Photovoltaic

- Photovoltaic inverter ranking list replacement

- Uzbekistan photovoltaic module inverter manufacturer

- Photovoltaic inverter requires rectifier cabinet

- Energy storage inverter and photovoltaic panels

- Photovoltaic inverter reverse development

- New photovoltaic inverter for sale

- QIN Photovoltaic Inverter

- Photovoltaic inverter load reduction

- Grid-connected inverter photovoltaic folding container

Solar Storage Container Market Growth

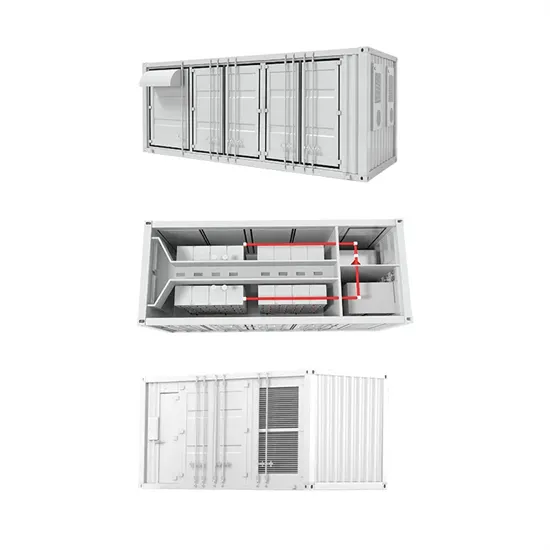

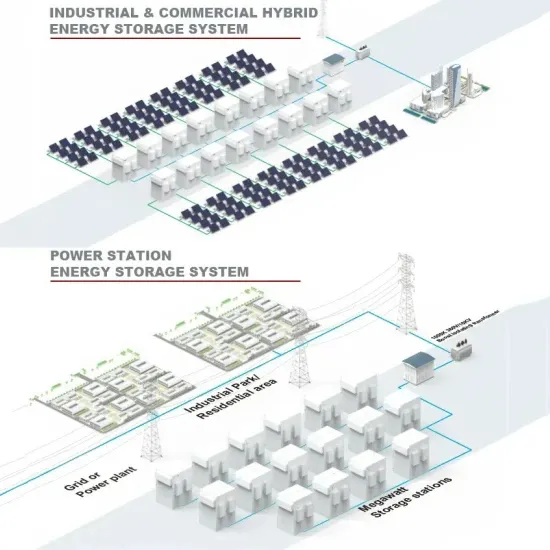

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.