bus tie breaker原理

bus tie breaker原理-Bus Tie Breaker通常由一个机械开关和一个控制系统组成。机械开关负责连接或切断两个母线之间的电路,而控制系统则负责监测电力系统的状态并控制机械开关的操作。

Bus Tie Breakers and Switches

Apr 18, 2025 · Move the pointer over the breaker and right-click. Edit options appear as shown in the figure above. Click Rotate > 90°. The breaker orientation changes from vertical to

Bus duct disconnect in croatia

Providing ideal top quality Bus duct disconnect in croatia items,we are professional manufacturer in China.Wining the majority of the crucial certifications of its sector,our Bus duct disconnect in

Transmission Bus Configuration Design Philosophy

Jun 14, 2024 · Transmission Bus Configuration Design Philosophy The intent of this document is to provide bus configuration guidelines for new substations interconnected to PECO''s bulk

Analysis of Advantages and Disadvantages of Closed

Oct 25, 2024 · configuration equipment no 3 operations. requirements breakers intended closed bus-ties to provide redundancy breakers reliability of closed classification for should closed

High-speed busbar transfer HBT

Mar 13, 2024 · Circuit-breaker control Control of two circuit-breakers Inclusion of bus-tie breaker by configuring two HBT functions Supervision of operating status Plausibility check

Understanding Bus Tie Breakers: Functionality

Sep 14, 2024 · Bus tie breakers are an essential component of reliable electrical systems, providing flexibility and redundancy in power distribution. They are

Bus tie breaker | PPM 300 controller by DEIF

The PPM 300 Bus tie breaker controller is part of the DEIF PPM 300 range of versatile controllers with built-in multi-master power management features. The range offers variants designed for

bustie这个单词是什么意思?_百度知道

May 23, 2010 · bustie这个单词是什么意思?肯定是bus tie,或者是 bus-tie,意思是:母线联络,母联,汇流条馈电线。你看看说不说得通。bus tie switch 母线联络开关bus-tie-in 汇电

Bus Tie Breaker: A Key Component in Electrical Power

A Bus Tie Breaker is an essential device used in electrical systems to connect or isolate individual sections of a switchboard. In maritime and offshore operations, particularly in vessels

Deep Sea Electronics DSE8680 Synchronising Generator Bus Tie

Description The DSE 8680 is an intelligent control module designed to control a generator bus-tie breaker. The control module features technology that automatically manages the

Bus Tie Circuit Breakers | Products & Suppliers | GlobalSpec

Find Bus Tie Circuit Breakers related suppliers, manufacturers, products and specifications on GlobalSpec - a trusted source of Bus Tie Circuit Breakers information.

Bus Tie Breakers and Switches

Sep 26, 2023 · Drag the tie breaker''s remaining leader to the bottom right bus. After it connects, drag the tie breaker''s symbol to be centered between the two buses. After the tie breaker is

Bus tie breakers not closing before synchronizing power stations

Jul 30, 2008 · At one stage the earthquake tremor occurs and causes the bus tie circuit breakers to opened by protection relays. So when we started up we had a problem with the bus tie

Electrical Power Distribution System Onboard

6 days ago · This allows the main generators to power the ship''s entire electrical system. If there is a failure of the main generators, the bus tie breaker will

RESIDUAL BUS MAIN-TIE-MAIN AUTOMATIC TRANSFER

Oct 18, 2013 · A more desirable operation is to perform a closed-transition manual transfer operation by using PB02 on the tie breaker relay, or the tie breaker''s CS/C mounted on the

6 FAQs about [Factory price bus tie breaker in Croatia]

What is a bus tie breaker power management system?

The power management system also ensures that enough power is available on each busbar section after the bus tie breaker opens. A DEIF power management system can include as many Bus tie breaker controllers as necessary. Part of the versatile PPM 300 range

How many bus tie breaker controllers can a Deif power management system include?

A DEIF power management system can include as many Bus tie breaker controllers as necessary. Part of the versatile PPM 300 range The PPM 300 Bus tie breaker controller is part of the DEIF PPM 300 range of versatile controllers with built-in multi-master power management features.

What is a bus tie breaker controller?

The controller is designed to be part of a DEIF power management system which ensures that all breaker operations are carried out in a fast, efficient, and safe manner: Before closing the bus tie breaker, the power management system synchronises the busbar sections, and before opening the bus tie breaker, the system de-loads the bus tie breaker.

What is a tie breaker?

A tie breaker is a type of circuit breaker that connects two sections of an electrical bus serving different power sources. They are commonly used to connect electrical systems to power sources and load circuits, as well as to protect people and equipment from overcurrents.

What is a PPM 300 bus tie breaker controller?

The PPM 300 Bus tie breaker controller is designed for controlling a single bus tie breaker and supports ring busbar connections.

What is a bus tie breaker interlock?

The bus tie breaker interlock prevents the main generators and the emergency generator from being connected to the emergency switchboard at the same time. This helps to prevent electrical accidents. Shore supply can be used to power the ship's electrical system when the ship is docked.

Update Information

- Factory price bus tie breaker in Puerto-Rico

- Factory price bus tie breaker in Colombia

- High quality factory price bus tie breaker Seller

- Factory price bus tie breaker in Poland

- Best factory price bus tie breaker Factory

- Factory price furnace breaker in Cebu

- Factory price circuit breaker in Mauritania

- Factory price voltage breaker in Belgium

- Factory price socket breaker in Cyprus

- Best factory price contact breaker exporter

- Motor circuit breaker factory in Croatia

- Factory price contact breaker in Uae

- China factory price contact breaker Wholesaler

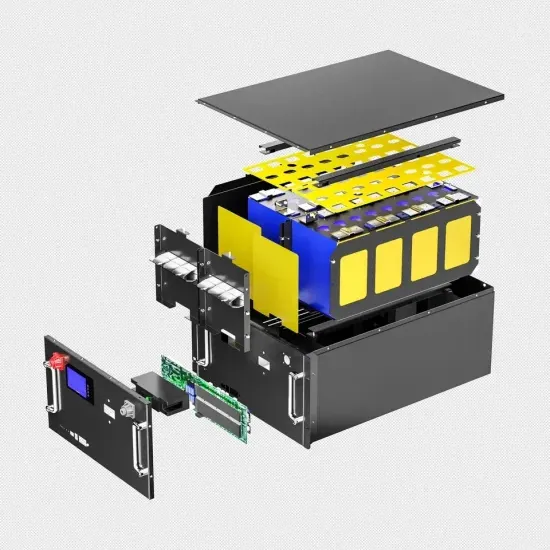

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.