Multi-factor aging in Lithium Iron phosphate batteries:

Mar 15, 2025 · However, lithium-ion batteries undergo capacity degradation and performance decline over time, which limits their practical applications. Battery performance degradation

Portable Energy Storage Solutions That Empower Outdoor

Aug 8, 2025 · Why Choose Lithium Iron Phosphate (LiFePO₄) Batteries for Outdoor Activities? Lithium iron phosphate (LiFePO₄) batteries are increasingly becoming the preferred choice for

INTRODUCTION TO LITHIUM IRON PHOSPHATE

Comparison of the life cycles of lithium iron phosphate and lead-acid batteries Figure: Lithium iron phosphate batteries achieve around 2,000 cycles, while lead-acid batteries only go through

Lithium iron phosphate LFP cathode active material 15365

Our battery grade lithium iron phosphate powder is a state-of-the-art cathode active material used in lithium-ion batteries. The material is a powdered form of lithium iron (II) phosphate or lithium

Understanding Lithium Iron Phosphate (LiFePO4) Batteries

Jul 26, 2024 · Lithium iron phosphate batteries are heat-resistant, with thermal values reaching between 350 to 500 degrees Celsius. Lithium iron phosphate batteries have a substantial

Lithium Iron Phosphate (LiFePO4) Battery

Oct 28, 2015 · Lithium Iron Phosphate (LiFePO4) Battery Features of LiFePO4 Battery Longer Cycle Life: Offers up to 20 times longer cycle life and five times longer float/calendar life than

Estimating the tipping point for lithium iron phosphate batteries

Jan 1, 2025 · Our model – which considers tradeoffs between battery capacity and weight – enumerates a range ''tipping point'' of 373.52 miles, beyond which NMC batteries consistently

How Does A Lithium Iron Phosphate Battery Work?

May 26, 2025 · Lithium Iron Phosphate (LiFePO4) batteries operate through the movement of lithium ions between a cathode made of LiFePO4 and a graphite anode during

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

Recycling of lithium iron phosphate batteries: Status,

Jul 1, 2022 · The recycling of retired power batteries, a core energy supply component of electric vehicles (EVs), is necessary for developing a sustainable EV industry. Here, we

LiFePO4 battery (Expert guide on lithium iron

Jun 4, 2021 · Lithium Iron Phosphate (LiFePO4) batteries continue to dominate the battery storage arena in 2025 thanks to their high energy density, compact

How is the capacity of the lithium iron phosphate actually

The weight specific energy and volume specific energy of lithium iron phosphate are: Batteries of pure electric vehicle: about 110 wh/kg; 210 wh/L Batteries of hybrid electric vehicle: about 65

Lithium Iron Phosphate (LiFePO4) Battery

Oct 28, 2015 · Wider Temperature Range: -20 C~60 C. Superior Safety: Lithium Iron Phosphate chemistry eliminates the risk of explosion or combustion due to high impact, overcharging or

Lithium iron phosphate battery

The lithium-iron phosphate battery or LFP battery is a variant of the lithium-ion battery with a cell voltage of 3.2 V to 3.3 V. In contrast to conventional lithium cobalt (III) oxide (LiCoO2)

Carbon emission assessment of lithium iron phosphate batteries

Nov 1, 2024 · The demand for lithium-ion batteries has been rapidly increasing with the development of new energy vehicles. The cascaded utilization of lithium iron

LiFePO4 Power Station: All You Need to Know –

Feb 27, 2024 · A LiFePO4 battery, or Lithium Iron Phosphate battery, represents a type of lithium-ion battery that uses lithium iron phosphate as the cathode

Modeling of capacity attenuation of large capacity lithium iron

Oct 13, 2024 · As the market demand for energy storage systems grows, large-capacity lithium iron phosphate (LFP) energy storage batteries are gaining popularity in electroche

6 FAQs about [What is the capacity of the lithium iron phosphate battery station cabinet ]

What is a lithium iron phosphate battery?

1. Introduction to lithium iron phosphate battery Lithium iron phosphate (lithium iron phosphate, LiFePO4, reviated as LFP) is apositive electrode material for lithium-ion batteries, which has the ability to insert and extract lithium ions in lithium-ion batteries.

What is lithium iron phosphate (LiFePO4)?

Lithium iron phosphate (LiFePO4) is a critical cathode material for lithium-ion batteries. Its high theoretical capacity, low production cost, excellent cycling performance, and environmental friendliness make it a focus of research in the field of power batteries.

Are lithium iron phosphate batteries safe?

Yunfeng Song Lithium iron phosphate (LFP) batteries have gained widespread recognition for their exceptional thermal stability, remarkable cycling performance, non-toxic attributes, and cost-effectiveness. However, the increased adoption of LFP batteries has led to a surge in spent LFP battery disposal.

How long does a lithium phosphate battery last?

Lead-acid batteries have a maximum life of 1 -1.5 years, while lithium iron phosphate batteries with the same weight have a theoretical life of 7 -8 years when they are used under the same conditions. Considered comprehensively, its performance-price ratio is four times that of a lead-acid battery in theory.

What is lithium iron phosphate chemistry?

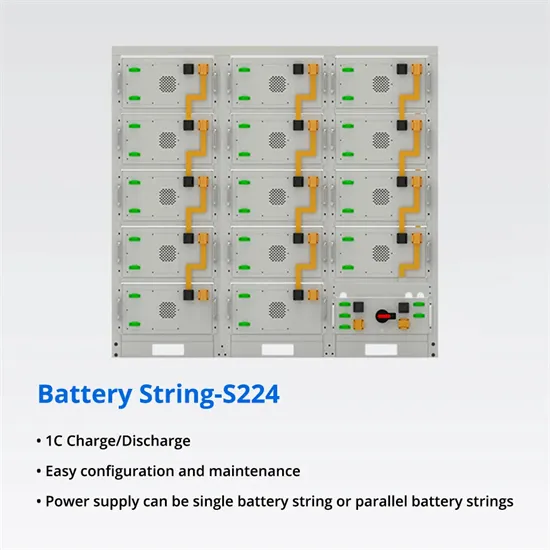

Superior Safety: Lithium Iron Phosphate chemistry eliminates the risk of explosion or combustion due to high impact, overcharging or short circuit situation. Increased Flexibility: Modular design enables deployment of up to four batteries in series and up to ten batteries in parallel. Max. Charge Current Continuous Current Max.

What are the performance requirements of lithium-iron-phosphate battery using LiFePo 4?

The lithium-iron-phosphate battery using LiFePO 4 as the anode has good performance requirements, especially in large discharging current rate discharging with 5–10C, stable discharging voltage, safety with no combustion, no explosion, number of life cycles, and no pollution to the environment.

Update Information

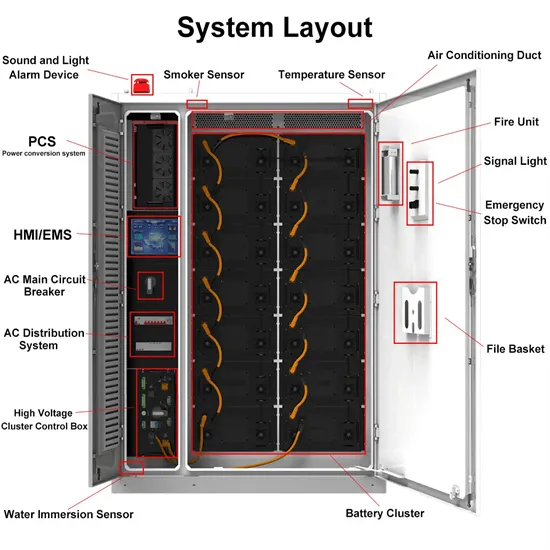

- What parts does the lithium iron phosphate battery station cabinet contain

- Lithium iron phosphate battery station cabinet over-discharge

- How about lithium iron phosphate battery for photovoltaic energy storage cabinet

- What does the lithium battery station cabinet system consist of

- Danish lithium iron phosphate energy storage battery cabinet

- Base station lithium iron phosphate battery outdoor communication site

- What is the prospect of lithium battery station cabinet

- Lithium cobalt oxide battery station cabinet cover

- How to connect the lithium battery station cabinet control system

- Turkmenistan lithium battery station cabinet system

- Suriname lithium battery station cabinet customization cost

- Rechargeable lithium iron phosphate battery pack

- Ghana lithium iron phosphate energy storage battery

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.