Cost and price projections of synthetic active materials for redox flow

Jul 1, 2021 · Synthetic organic and organometallic active materials for flow batteries offer a large design space in terms of solubility, redox potential, kinetic activity, and stability. Price is also a

Low-cost all-iron flow battery with high performance

Oct 1, 2022 · New flow batteries with low-cost have been widely investigated in recent years, including all-liquid flow battery and hybrid flow battery [12]. Hybrid flow batteries normally

Assessing the levelized cost of vanadium redox flow batteries with

Jun 1, 2020 · The vanadium redox flow battery (VRFB) is arguably the most well-studied and widely deployed RFB system. At the time of writing, there are approximately 330 MW of

Vanadium flow batteries at variable flow rates

Jan 1, 2022 · The electrolyte components (acid, vanadium, and water) are the highest cost component of vanadium flow batteries; the concentration and solubility of vanadium play a key

Vanadium redox flow batteries: A comprehensive review

Oct 1, 2019 · 4 Low Cost - The cost of a storage technique often correlates with the technical maturity. As more manufacturers produce the product/components, the more competitive the

Sustainable recycling and regeneration of redox flow battery components

Feb 1, 2025 · As the demand for large-scale sustainable energy storage grows, redox flow batteries (RFBs), particularly all-vanadium RFBs (VRFBs), have emerged as a promising

Component-cost and performance based comparison of flow

Oct 1, 2015 · Abstract Flow batteries are a promising grid-storage technology that is scalable, inherently flexible in power/energy ratio, and potentially low cost in comparison to conventional

A General, Analytical Model for Flow Battery Costing and

Jul 19, 2018 · We seek ultimately to optimize redox flow battery (RFB) stacks for the grid; to do so on a reasonable timescale calls for an analytical formulation. We hereon make several

Cost structure analysis and efficiency improvement and cost

Jun 19, 2025 · Taking an all vanadium flow battery with a basic energy storage capacity of 10 kW/120 kWh as an example [1], its cost mainly includes three almost equal parts: stack cost,

A comparative study energy consumption and costs of battery

Mar 1, 2016 · Despite the long-term benefit of battery electric vehicles (BEVs) to customers and environment, the initial cost and limited driving range present significant barriers for wide

Electrolyte tank costs are an overlooked factor in flow battery

Jan 3, 2025 · Standardization of flow battery components and the development of high-voltage chemistries are highlighted as paths towards decreasing costs and achieving greater market

Microsoft Word

Dec 11, 2020 · It is assumed that stacks for flow batteries would be run at various power densities depending on E/P ratio. That means for a high E/P ratio, since electrolyte costs dominate, the

What Are Flow Batteries? A Beginner''s Overview

Jan 14, 2025 · Understanding the key components of flow batteries is crucial to appreciating their advantages and challenges. Flow batteries consist of several critical parts, each contributing to

Techno-Economic Analysis of Material Costs for Emerging Flow Batteries

Feb 2, 2022 · In this study, we present a techno-economic analysis to evaluate the cost of materials in three emerging redox flow battery products: vanadium pentoxide redox flow

Eutectic electrolyte and interface engineering for redox flow batteries

Jun 1, 2022 · Abstract Eutectic electrolytes based redox flow batteries (RFBs) are acknowledged as promising candidates for large-scale energy storage systems on account of low cost and

Estimation of Capital and Levelized Cost for Redox Flow

Nov 9, 2012 · PNNL Iron-Vanadium (1.5 M, 5M HCl -5 to 55 oC) Estimated capital cost & levelized cost for 1 MW systems with various E/P ratios Validated PNNL model using PNNL 1 kW, 1

Cost and performance model for redox flow batteries

Feb 1, 2014 · Developed redox flow battery cost performance model and validated with stack data. The model allows determination of dominant costs for each chemistry and application.

A review of transport properties of electrolytes in redox flow batteries

Feb 1, 2025 · Therefore, the electrolyte is one of the most important components in redox flow batteries and its physicochemical properties greatly determine the battery performance. Here,

Economics of vanadium redox flow battery membranes

Jul 15, 2015 · The membrane is a key component of the vanadium redox flow battery (VRFB) in terms of electrochemical performance as well as costs. The standard material Nafion ® is cost

6 FAQs about [Cost ratio of each component of flow battery]

What is the capital cost of flow battery?

The capital cost of flow battery includes the cost components of cell stacks (electrodes, membranes, gaskets and bolts), electrolytes (active materials, salts, solvents, bromine sequestration agents), balance of plant (BOP) (tanks, pumps, heat exchangers, condensers and rebalance cells) and power conversion system (PCS).

How is cost distribution determined in a flow battery system?

The cost distribution by battery component is determined to highlight the major cost drivers in battery systems. Lastly, uncertainty due to price variability is evaluated. For the TEA model, data on the prices of key materials used in the flow battery systems are required.

Are flow batteries worth it?

While this might appear steep at first, over time, flow batteries can deliver value due to their longevity and scalability. Operational expenditures (OPEX), on the other hand, are ongoing costs associated with the use of the battery. This includes maintenance, replacement parts, and energy costs for operation.

What is a cost model for redox flow batteries?

A cost model is developed for all vanadium and iron–vanadium redox flow batteries. Electrochemical performance modeling is done to estimate stack performance at various power densities as a function of state of charge and operating conditions.

Are flow batteries a cost-effective choice?

However, the key to unlocking the potential of flow batteries lies in understanding their unique cost structure and capitalizing on their distinctive strengths. It’s clear that the cost per kWh of flow batteries may seem high at first glance. Yet, their long lifespan and scalability make them a cost-effective choice in the long run.

How do you calculate the cost of a flow battery?

Electrode materials includes bipolar plates, end-plates and graphite felts. The total costs of flow battery (C RFB) are expressed in terms of $ (kW h) −1 through dividing the costs of all these components (Cstack, Celectrolytes, CBOP and CPCS) by the required energies of the applications (Etotal = P × tdischarge, where P = Vdischarge × tdischarge).

Update Information

- Iron-vanadium liquid flow battery cost

- How much does a flow battery for a communication base station cost

- Iron-zinc flow battery cost

- Zinc-bromine flow battery in parallel

- Hechu New Material Liquid Flow Battery

- What is vanadium liquid flow battery

- 4G communication base station flow battery budget

- Cameroon 5G communication base station lithium ion battery cost

- Communication base station flow battery range

- Serbia vanadium flow battery grid connected

- Power Battery Iron and Chromium Flow Batteries

- How much does it cost to replace the battery at the site

- Tokyo Flow Battery Energy Storage Battery

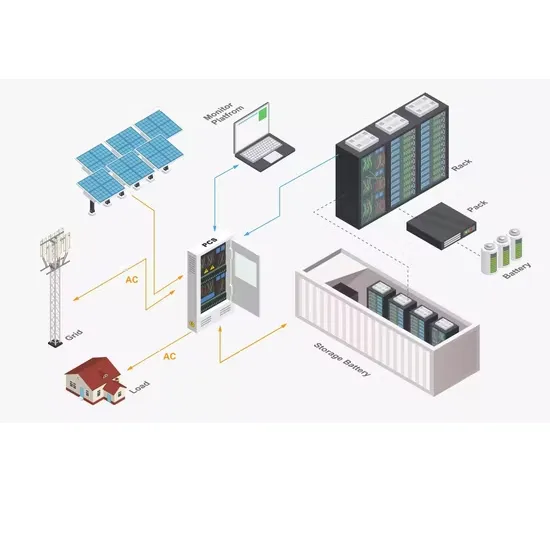

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.