Eaton three-phase UPS battery handbook

Apr 3, 2025 · Battery failure is a leading cause of UPS load loss. Knowing how to properly maintain UPS batteries will help you manage your IT power more efficiently and avoid power

DC Battery Rack Grounding

Jul 18, 2017 · In my years as a substation electrician we never grounded battery racks. All substations I''m familiar with have ungrounded DC because a ground fault on either polarity will

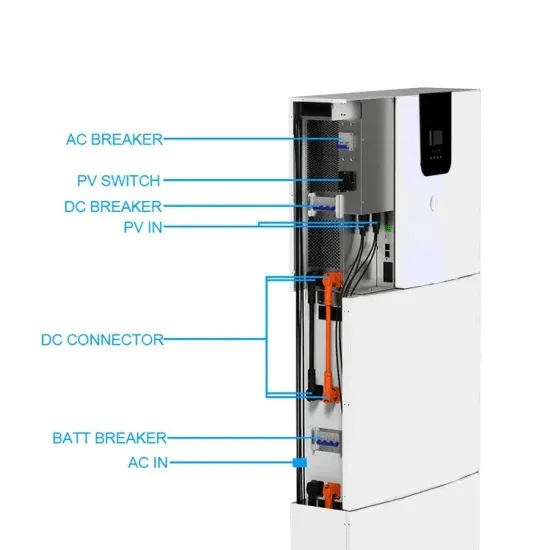

UPS Installation Guide-Custom Lithium ion

Oct 10, 2022 · The neutral wire is drawn from the negative pole or positive pole of the 8th battery in the battery pack, and then continues to connect in series. A

SL-25657_REV3_01-21

Feb 27, 2020 · Connect the ground wire (PE) to the ground screw on the rear of the UPS. Place the battery cable ring lug on the terminal block, add the insulating plate, then insert the screw

How to Ground a Server Rack | Requirements of

Apr 29, 2023 · Bonding (or grounding) is a system of protective measures, which is implemented to prevent electric shocks when touching metal parts of energy

How to Design a Grounded Power Supply System

Jun 20, 2018 · How to Design a Grounded Power Supply System Transformerless uninterruptible power supply (UPS) systems operate ungrounded during power transfer to a backup source,

Avaya maintenance bypass owner''s manual

Sep 3, 2024 · UPS with Bypass Electrical Installation NOTE If you have a plug-receptacle unit, continue to "Battery Cabinet Installation" on page 57 for installing optional battery cabinets or

How is a EG4 Battery grounded without rack?

May 17, 2022 · The EG4 battery manual: Step 3. Electrical Installation 1. Grounding wire. Affix a grounding wire of sufficient wire gauge from the battery module enclosure grounding screw

Overview of Grounding of APC UPS Power Supply Unit (part 2)

Apr 23, 2025 · 2. Grounding of UPS body part The APC UPS body, its casing, battery cabinet (rack), etc. need to be connected to the electrical grounding device using grounding wires.

VertivTM Liebert® ITA2 Battery Cabinet

Feb 27, 2020 · Connect the ground wire (PE) to the ground screw on the rear of the UPS. Place the battery cable ring lug on the terminal block, add the insulating plate, then insert the screw

/15/20KVA UPS Battery Cabinet Installation and

Jan 9, 2025 · Installation or replacement of batteries must be located in a SERVICE ACCESS AREA: The service manual shall include the following instructions for battery replacement and

/15/20KVA UPS Battery Cabinet Installation and

Jan 9, 2025 · SAVE THESE INSTRUCTIONS This manual contains important safety instructions. Read all safety, installation and operating instructions before installing the Battery Bank. This

Earthing is a Critical Safety Feature in UPS Systems

Feb 28, 2025 · Locate the Earthing Terminal: Identify the earthing terminal on the UPS back panel (marked with ⏚ or "Ground"). Prepare the Earth Wire: Strip

Liebert® EXS External Battery Cabinet Installer/User Guide

Jan 31, 2024 · For battery cabinets that are connecting to a VertivTM Liebert® EXS UPS, see Figure 2.1 on page 8, cables will run from the positive, negative and neutral busbars of the

6 FAQs about [How to connect the ground wire of UPS battery cabinet]

How do I connect a battery to my ups?

Securely connect each battery module. Press the battery connector into the UPS until it is firmly connected. A battery that is not fully connected will cause erratic UPS operation, abnormal error messages and connected equipment may not receive battery power during power outages.

How do you ground a ups?

The wire should have low resistance to ensure effective grounding. The earth wire from the UPS is connected to the building’s main earthing point, such as a grounding rod or earthing busbar. Identify the earthing terminal on the UPS back panel (marked with ⏚ or “Ground”).

How do you connect ups to a building?

Attach the stripped end of the earth wire to the earthing terminal on the UPS. Tighten the terminal screw securely to ensure a good connection. Run the other end of the earth wire to the building’s main earthing point. Ensure the connection is secure and meets local electrical codes.

What kind of wire is used to connect ups to a building?

Usually made of brass or another conductive material for reliable conductivity. A thick, insulated copper wire (usually green or green-yellow) connects the UPS to the building’s earthing system. The wire should have low resistance to ensure effective grounding.

What is grounding in a ups?

Earthing (or grounding) is a critical safety feature in Uninterruptible Power Supply (UPS) systems. It ensures the safe operation of the UPS and connected devices by providing a path for fault currents to dissipate into the ground, preventing electric shock, equipment damage, and fire hazards.

Where is the earthing connection on a ups?

The earthing connection is typically located on the back panel of the UPS and is marked with the earth symbol (⏚) or labeled as “Ground”. Here’s how it works: A dedicated screw terminal or connector for attaching the earth wire. Usually made of brass or another conductive material for reliable conductivity.

Update Information

- How to connect the ground wire in the battery cabinet

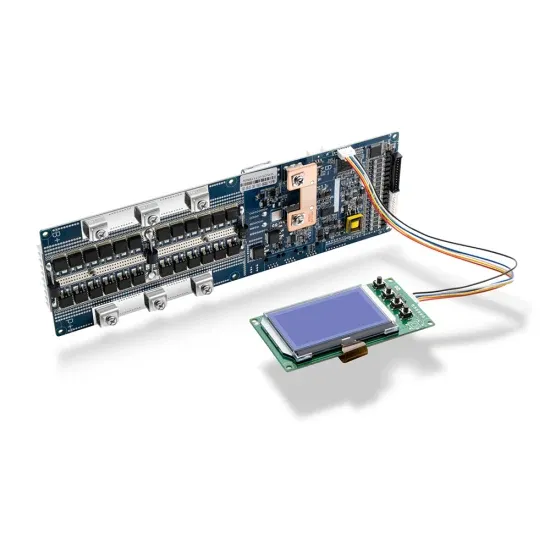

- How to connect the lithium battery station cabinet control system

- How to connect the bridge to the battery cabinet ESS power base station

- How to match UPS power supply with battery cabinet

- How many batteries are in the UPS battery cabinet

- UPS battery cabinet price

- How to calculate the storage time of battery cabinet

- How much can the new energy battery cabinet sell for

- How heavy is the 4G outdoor communication base station battery energy storage system cabinet

- How to replace the lithium battery in Cairo outdoor communication battery cabinet

- How much does a photovoltaic energy storage battery cabinet weigh

- How to measure the electricity of new energy battery cabinet

- How does the liquid-cooled energy storage battery cabinet work

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.