Energy and environmental footprints of flywheels for utility

Jan 1, 2021 · The net energy ratio is a ratio of total energy output to the total non-renewable energy input over the life cycle of a system. Steel rotor and composite rotor flywheel energy

Flywheel Storage Systems | SpringerLink

Dec 17, 2019 · The components of a flywheel energy storage systems are shown schematically in Fig. 5.4. The main component is a rotating mass that is held via magnetic bearings and

Composite Flywheels for Energy Storage

Jun 7, 2017 · Energy storage flywheels are generally useful in power conditioning applications, i.e., when there is a mismatch between the power generated and the power required by the

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

DOE ESHB Chapter 7 Flywheels

Mar 17, 2022 · broad range of applications today. In their modern form, flywheel energy storage systems are standalone machines that absorb or provide electricity to an application.

The most complete analysis of flywheel energy storage for

Aug 23, 2023 · Flywheel energy storage is an energy storage technology with high power density, high reliability, long life, and environmental friendliness. It is characterized by full magnetic

Concrete flywheel storage system for residential

Jun 21, 2021 · A French start-up has developed a concrete flywheel to store solar energy in an innovative way. Currently being tested in France, the storage

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · Energy storage flywheels are usually supported by active magnetic bearing (AMB) systems to avoid friction loss. Therefore, it can store energy at high efficiency over a long

Flywheel energy storage principle video tutorial

With the increasing pressure on energy and the environment, vehicle brake energy recovery technology is increasingly focused on reducing energy consumption effectively. Based on the

Enhancing vehicular performance with flywheel energy storage

Dec 10, 2024 · Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

Understanding Flywheel Energy Storage: Does High

Jan 4, 2022 · Understanding Flywheel Energy Storage: Does High-Speed Really Imply a Better Design? This paper will review how energy is stored in a flywheel using the simple concept of

The Flywheel Energy Storage System: An Effective Solution

Mar 7, 2020 · Today the role of electricity is very important because it must meet the need for continuous power supply for all manufacturing industries and human social life

Analysis of a flywheel energy storage system for light rail

Jul 15, 2016 · These models are used to study the energy consumption and the operating cost of a light rail transit train with and without flywheel energy storage. Results suggest that

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Flywheel Energy Storage (FES): Exploring Alternative Use

May 4, 2017 · Flywheel Energy Storage had the second largest total score, and additionally is adaptable for an urban commercial building. FES also works well for peak shaving and peak

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheel Energy Storage (FES) system is an electromechanical storage system in which energy is stored in the kinetic energy of a rotating mass. Flywheel systems are

A review of flywheel energy storage rotor materials and

Dec 25, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · An early unit from the project, an M25 with a power capacity of 6.25kW and 25kWh energy storage capacity flywheel, was temporarily sent to a site in Subic Bay Philippines by

6 FAQs about [Energy consumption when flywheel energy storage]

Are flywheel energy storage systems feasible?

Flywheel energy storage systems are feasible for short-duration applications, which are crucial for the reliability of an electrical grid with large renewable energy penetration. Flywheel energy storage system use is increasing, which has encouraged research in design improvement, performance optimization, and cost analysis.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

Are flywheel batteries a good option for solar energy storage?

However, the high cost of purchase and maintenance of solar batteries has been a major hindrance. Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a low environmental footprint.

How much energy does a flywheel produce?

The net energy ratios of steel and composite flywheels are 2.5–3.5 and 2.7–3.8. The GHG emissions of steel and composite flywheels are 75–121 and 49–95 kg CO 2 eq/MWh. Flywheel energy storage systems are feasible for short-duration applications, which are crucial for the reliability of an electrical grid with large renewable energy penetration.

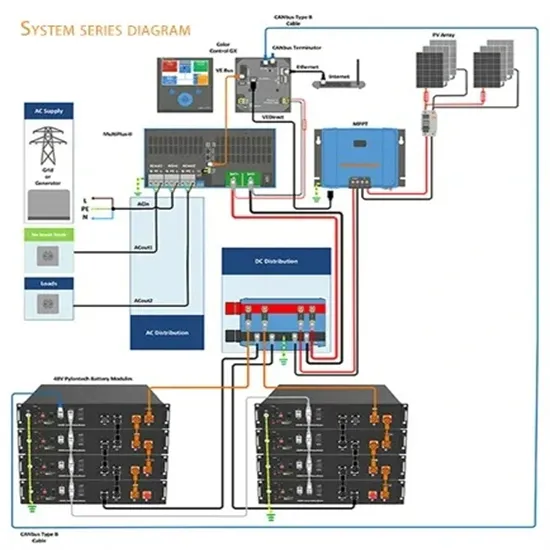

What are the components of a flywheel energy storage system?

The main components of a flywheel energy storage system are a rotor, an electrical motor/generator, bearings, a PCS (bi-directional converter), a vacuum pump, and a vacuum chamber . During charging, the rotor is accelerated to a high speed using the electrical motor.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Update Information

- Where are the solar base stations and flywheel energy storage in Ireland

- Classification standards for flywheel energy storage photovoltaics for communication base stations

- Flywheel energy storage can

- A kind of flywheel energy storage

- Flywheel Energy Storage SOC

- How to develop flywheel energy storage for communication base stations

- Windhoek 5G communication base station flywheel energy storage application

- How much does a micro flywheel energy storage battery cost

- Superconducting energy storage flywheel

- What is the price of flywheel energy storage

- Turkmenistan Construction Engineering Flywheel Energy Storage

- Is the flywheel energy storage at the communication base station the bottom of the tower

- Is there flywheel energy storage now

Solar Storage Container Market Growth

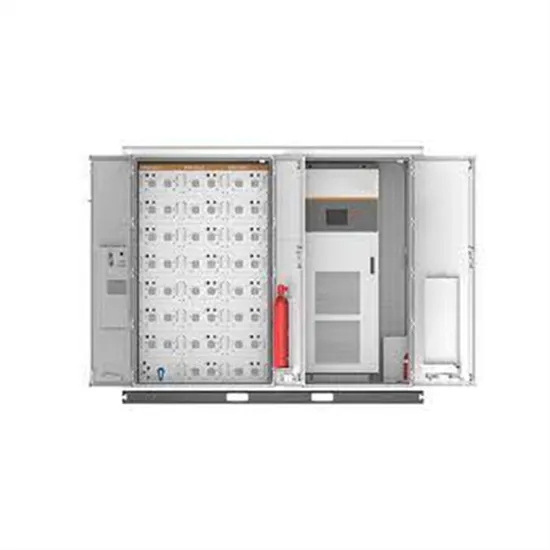

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.