A Guide To UPS Room Layout | Carter Sullivan

May 4, 2020 · We explore the fundamentals of UPS room layout and the things you need to consider when deciding where to locate your essential power protection systems.

Requirements for the Battery Installation Site

Nov 28, 2024 · The installation site must meet the requirements of the local fire protection regulations. The available height must be greater than the tilt dimension of the battery cabinet.

Lead-acid battery installation requirements in the

The Occupational Safety and Health Administration (OSHA)''''s regulations for forklift battery charging and maintenance outline strict requirements that each battery room be equipped with

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · 6. SYSTEM SPECIFICATIONS 6.1 BATTERIES specific information. Type: Valve Regulated Lead Acid (VRLA), sealed, non-spilla Only cabinets with Flame Retardant Batteries

Battery cabinet installation room specifications

The BC-1(R) provides an internal terminal assembly for wiring the batteries to the fire alarm control panel power supply terminals. Install the battery cabinet in accordance with CAN/ULC

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Battery placement in the cabinet

Do battery cabinets need to be locked? Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept locked, they

Installation specification of battery cabinet in computer room

This document provides requirements for battery room design and installation at Saudi Aramco facilities. It discusses physical requirements such as room size, interior walls, doors, and

How to correctly install lithium battery energy

Mar 25, 2024 · In this guide, we will introduce the correct installation steps after receiving the lithium battery energy storage cabinet, and give the key steps

General requirements for the installation of UPS

Oct 21, 2023 · It''s best to install batteries in an open rack rather than a closed cabinet for several reasons: Open racks are better than closed cabinets for

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Eaton 9390 Integrated Battery Cabinet (Models IBC-S

Aug 16, 2024 · The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large

UPS/DC Battery Room, Equipment Installation Requirements

Cabinets or racks shall be provided in the battery room for storing maintenance tools and safety equipment. These cabinets and racks shall be acid or alkaline resistant as applicable. Battery

Battery cabinet installation location requirements

How to correctly install lithium battery energy storage cabinet? Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid

Can the battery cabinet be located together with the

Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept locked, they can be located in a computer room or

Battery cabinet in computer room exploded

This manual provides instructions regarding safety, storage, installation, operation and o Only cabinets with flame retardant batteries are suitable for computer room use! The battery cabinet

Adding a battery cabinet to the computer room

Do battery cabinets need to be locked? Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept locked, they

Battery Room requirements | Eng-Tips

Dec 17, 2009 · If a high voltage terminal station (in which I would expect redundant battery supplies) than it makes sense to have your batteries in a separate room. Further more the

BC58 Battery Cabinet Installation, Operation,

6.2.1 EQUIPMENT LOCATION Prior to installation, verify floor loading requirements and all applicable codes pertaining to the related equipment. Environmental conditions should also be

Designing Industrial Battery Rooms: Fundamentals and

Industrial battery rooms require careful design to ensure safety, compliance, and operational efficiency. This article covers key design considerations and relevant standards. 1. Space

Battery Room Ventilation and Safety

Mar 15, 2023 · The signs shall state that the room contains lead-acid battery systems, that the battery room contains energized electrical circuits, and that the battery electrolyte solutions are

Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

Powerware 9390 Integrated Battery Cabinet (Models IBC

May 2, 2022 · During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

6 FAQs about [Battery cabinet installation site in computer room]

Can a battery be installed in a computer room?

Sometimes they are installed in the same room as the UPS (i.e., electrical equipment room). Local or regional codes may dictate whether batteries are permitted in an electrical room. Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets.

Where are ups installed in a computer room?

Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets. The UPS and/or battery cabinets might be configured to look like standard computer equipment racks. Hazards

How do I set up an UPS battery room?

Open-rack battery rooms must be adjacent to the UPS room. Battery cabinets must be adjacent to the UPS equipment. Cable lengths from multiple cabinets should be kept as nearly identical as possible to prevent voltage drop variations. One cabinet should be able to hold at least one complete string of cells.

Can you put a battery in an electrical room?

Local or regional codes may dictate whether batteries are permitted in an electrical room. Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets. The UPS and/or battery cabinets might be configured to look like standard computer equipment racks.

Do battery cabinets need to be locked?

Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept locked, they can be located in a computer room or other rooms accessible by non-battery technicians.

What should be installed in a battery room?

Emergency lighting with compatible illumination level shall be installed to operate in the event of loss of mains power supply. Battery room doors shall open outward, away from the room, to the outside of the building, and be fitted with door closers and anti-panic (quick-release, quick-opening) hardware.

Update Information

- The lithium battery site cabinet in the computer room can be used directly

- Battery cabinet installation base station in weak current room

- Replacement of lithium iron phosphate battery cabinet units at site

- How is the energy battery cabinet at the Tbilisi site

- Vilnius site energy battery cabinet environmentally friendly electricity

- Energy storage cabinet site charging battery set

- Site Energy Battery Cabinet Free Agent

- Shared battery cabinet installation ESS power base station

- Spanish cabinet battery cabinet installation energy

- Lithium battery site cabinet energy storage liquid cooling

- 380vups battery cabinet installation

- Germany battery exchange cabinet site

- Telecom battery cabinet outdoor site

Solar Storage Container Market Growth

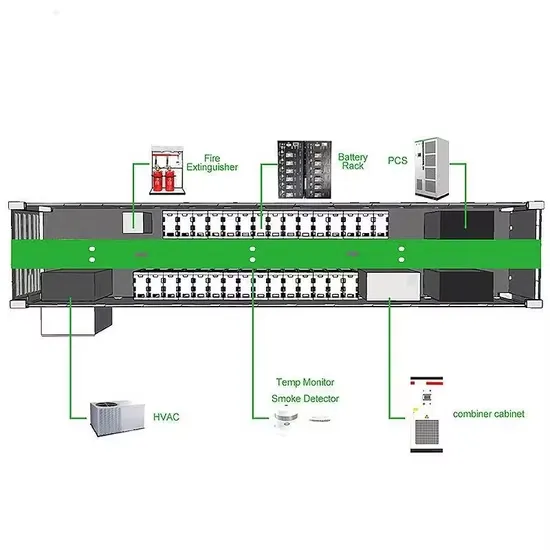

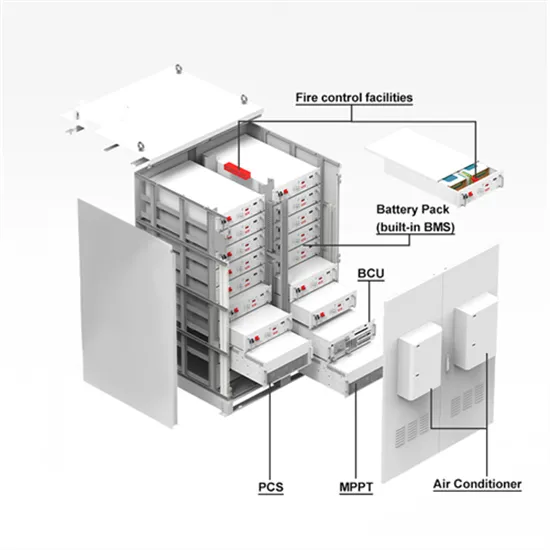

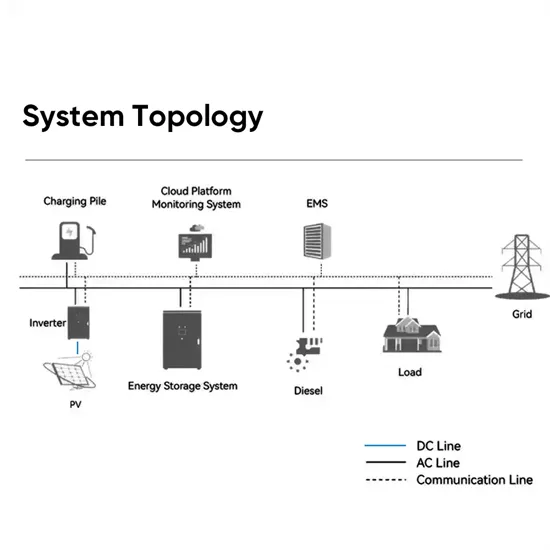

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.