Wind Turbine Inspection Solutions

Apr 1, 2022 · The Huangang and Hai''an offshore wind farms of Jiangsu Longyuan Offshore Wind Power Co., Ltd., a subsidiary of China Energy Investment Corporation, completed the first

5G Mobile Communication Base Station Electromagnetic

Dec 15, 2023 · The article 35 of the Regulations stipulates that "for the establishment of large-scale wireless radio stations (stations) and ground public mobile communication BS, their

Rules and Standards for Offshore Wind Power Farm Facilities

Oct 26, 2021 · Table 1 shows China''s existing technical standards for offshore wind power at each stage of project implementation, including but not limited to the following codes and standards.

The Application of Inspection Robot in Substation

Feb 8, 2023 · Inspection robot system architecture is shown in Fig. 1, the use of inspection robot for wireless communication devices, base station and mobile station system, to accomplish

Research on Offshore Wind Power Communication System

Feb 5, 2024 · In view of the special needs of the communication system, a communication system scheme for offshore wind farms based on 5G technology is proposed. </sec><sec>

Research on Offshore Wind Power Communication System

Feb 5, 2024 · <sec> <b>Introduction</b> Numerous equipment of offshore wind power projects is located on the ocean, and the inconvenient transportation makes operation

Three Dimensional Fully Autonomous Inspection Method for Wind Power

Download Citation | On Dec 16, 2022, Ying Zhou and others published Three Dimensional Fully Autonomous Inspection Method for Wind Power Employing Unmanned Aerial Vehicle Based

Wind Inspection and Testing Checklists

Mar 13, 2023 · These Checklists provide information on the Inspection and Testing activities to be carried out by the Applicant contractor at the end of the construction of a Wind system, in

China''s Largest Offshore Wind Power Equipment Testing

May 29, 2025 · Recently, the Dongying Wind Power Equipment Testing and Certification Innovation Base, designed by Shandong Electric Power Engineering Consulting Institute

A framework for condition assessment of communication

May 1, 2025 · Communication towers are the core equipment supporting mobile communication networks, and their security is crucial for the stable operation of communication systems.

Gansu Wind Power Company purchases a batch of Wuhan

As early as July 2023, General Manager Yang of Gansu Wind Power Company invited Manager Pang from Wuhan UHV to have a discussion on the technical issues of test equipment. During

Multi‐Layer Attention Network With Weather Suppression

Jul 10, 2025 · In order to solve the problems of heavy tasks, difficulty, remote location and harsh conditions of wind power equipment inspection, this paper proposes a power system

Communication Base Station Inspection | We Group E-Site

The answer often lies in overlooked communication base station inspections. With 5G deployments accelerating globally, 78% of telecom operators report unexpected downtime due

The Construction of China''s First National Offshore Wind Power

Dec 11, 2023 · Upon completion, the Offshore Wind Power Test Base will provide scientific research, test and verification, exchange and sharing services for upstream and downstream

Deploying UAV Base Stations in Communication

Dec 21, 2019 · 1.1 Background Wireless communications systems which include unmanned aerial vehicles (UAV) are capable of providing cost-e ective wireless connectivity for devices without

Flying Base Stations for Offshore Wind Farm Monitoring and

Jul 10, 2025 · Ensuring reliable and low-latency communication in offshore wind farms is critical for efficient monitoring and control, yet remains challenging due to the harsh environment and

Environmental Monitoring of Communication Base

Dec 18, 2020 · 1 Introduction With the rapid development of communication technology, the number of communi-cation base stations is also growing significantly. The operation

China''s first national-level offshore wind power

Dec 6, 2023 · It includes an onshore testing center and a test wind farm, with its main functions being the full-size ground testing of wind turbine units with six

Wind Power Equipment Manufacturing Supervision-CTI

CTI provides wind power equipment manufacturing supervision services related to industrial product inspection. CTI is committed to providing customers with the most cost-effective wind

Environmental Monitoring of Communication Base Station

Dec 19, 2020 · With the rapid development of communication technology, the number of communication base stations is also growing significantly. The operation environment of base

Design and realization of 5G mobile base station s

Feb 28, 2024 · The research work of this program design has basically reached the expected requirements, through the user requirements analysis, functional design, database design,

6 FAQs about [Inspection batch of wind power equipment for communication base stations]

Can wind energy be used to power mobile phone base stations?

Worldwide thousands of base stations provide relaying mobile phone signals. Every off-grid base station has a diesel generator up to 4 kW to provide electricity for the electronic equipment involved. The presentation will give attention to the requirements on using windenergy as an energy source for powering mobile phone base stations.

What is wind turbine inspection?

Wind turbine inspection falls under one of two categories: Inspection in service to ensure continuity of operation. Inspection during the manufacturing stages for wind turbines need to meet the challenges posed by working with such large structures, while still meeting productivity, financial and design requirements.

What is Twi doing with wind turbine inspection?

TWI has developed technologies as part of collaborative research projects related to wind turbine inspection, including: These are just some examples of our work in this area, while we are also working on other projects in different industries that could find future use in wind turbine inspection.

What is a wind checklist?

These Checklists provide information on the Inspection and Testing activities to be carried out by the Applicant contractor at the end of the construction of a Wind system, in order to connect it to the Distribution Network in KSA.

Who is eligible to use a wind system?

Eligible Consumer – Any Person supplied with electricity services for his own consumption. In this context, this term will also be used to refer to a User owning a Wind System. This term has also the same meaning of Customer, as defined in the Distribution Code.

What is a wind turbine unit?

Wind Turbine Unit – A wind turbine unit consists of the wind turbine, generator and converter, together with all plant and apparatus and any step-up transformer which related exclusively to the operation of that wind turbine.

Update Information

- Wind power cooling for communication base stations

- London s requirements for wind power construction of communication base stations

- What does wind power for communication base stations need

- How much does wind power cost for outdoor communication base stations

- Battery standards for wind power in Jerusalem communication base stations

- Planning scheme for wind power construction of communication base stations

- Wind power restoration status of North African communication base stations

- Wind power migration of communication base stations

- Where communication base stations and wind power cannot be built

- Regulations on wind and solar complementary power generation for Praia communication base stations

- Installation of power equipment for communication base stations

- Price of wind and solar hybrid equipment for Canadian communication base stations

- Does the energy storage battery used in communication base stations have wind power

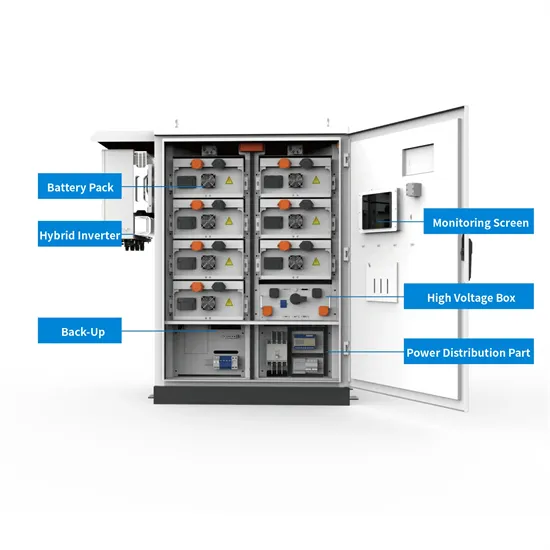

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.