Home | Wilson Transformer Company

Jan 20, 2024 · Established in 1933 with a proud history, Wilson Transformer Company (WTC) is Australia''s largest manufacturer of distribution and power transformer solutions operating two

Tengyi Transformers and Substations For Sale

Aug 19, 2025 · Tengyi offers comprehensive transformer and substation solutions tailored to meet the diverse needs of various industries. Our products are designed to ensure optimal

Transformer Protection Application Guide

May 28, 2013 · Transformer Protection Application Guide This guide focuses primarily on application of protective relays for the protection of power transformers, with an emphasis on

Transformer breaker for sale in melbourne

Providing best good quality Transformer breaker for sale in melbourne items,we''re specialist manufacturer in China.Wining most of the vital certifications of its sector,our Transformer

Subsidiaries & Joint Ventures | Wilson Transformer Company

EWT Transformer Sdn Bhd (formerly known as EPE Wilson Transformer Sdn Bhd) is a joint venture company whose principle shareholders are a Malaysian Bumiputra Company, Wira

The U.S. electric industry is not responding to

Feb 29, 2024 · In 2021, the Director of National Intelligence Council''s National Intelligence Estimate wrote: "China is the world''s leading supplier of advanced

Top 10 Transformer Manufacturers in China (2024 List)

Sep 19, 2024 · Top transformer manufacturers in China offer high-quality, customizable solutions. Explore reliable options with global certifications and expert support.

China Vacuum Circuit Breaker, Distribution Transformer,

Aug 12, 2025 · Shanghai Zikai Electric Co., Ltd.: We''re known as one of the most professional Vacuum Circuit Breaker, Distribution Transformer, Electrical Switchgear, Ring Main Unit, Load

Top 10 Transformer manufacturer China Products Compare

In this article, we''ll explore the leading transformer factories in China, comparing their capabilities, technologies, and what sets them apart in the industry. Product Details: Generic transformer

6 FAQs about [Transformer breaker in China in Melbourne]

Where are Melbourne-made transformers used?

As a result, our Melbourne-made transformers are currently being used in some 85 countries around the world. Our current customers include Siemens Mobility (previously Westinghouse/Invensys), , Tassal and many others, all of whom are most satisfied with our products. Our transformers operate at many Melbourne landmarks including:

Where are our Transformers made?

Our transformers are generally manufactured in these sizes: An extensive range of power supplies and variable transformers is also available. About one third of our power transformer production goes into Australian-made equipment for export. As a result, our Melbourne-made transformers are currently being used in some 85 countries around the world.

Where did the last 350mva 330/33/33kv power transformer go?

On Saturday, the last of the three 350MVA 330/33/33kV power transformers started its epic journey out of Melbourne to its final destination in NSW, at the site of the former Munmorah coal-fired power station, in a complex 9-day operation. With More >

Who is Wilson Transformer Company?

We support the majority of the electricity infrastructure providers and heavy electricity users and have a proven track record of supplying a wide range of transformer solutions across Australia and in targeted overseas markets. At Wilson Transformer Company, we build our products smart for life.

Can southern electronic services produce a custom transformer unit?

At the same time, we retain our ability to produce a single custom transformer unit or small numbers if so requested. Southern Electronic Services is a member of the Standards Association of Australia, and all our products are designed and tested to conform to relevant Australian and International Standards.

Did SES build a transformer?

SES also designed and built transformers for use on the Antarctic supply ship “RV Investigator” and its predecessor “Aurora Australis”. Another contract involved the design and supply of three-phase isolation transformer equipment and filters to IBM for use with their “3390” mainframe computers.

Update Information

- Transformer breaker in China in Sydney

- Cheap transformer breaker in China distributor

- Transformer breaker in China in Bahamas

- Transformer breaker in China in Chile

- Transformer breaker in China in Sweden

- Best breaker distribution in China Buyer

- Solid state breaker in China in Spain

- Best China circuit breaker outdoor manufacturer

- Best koten safety breaker in China Price

- Hot sale China bolt on circuit breaker Buyer

- Breaker distribution in China in Peru

- New circuit breaker in China in Myanmar

- Hot sale ground fault breaker in China for sale

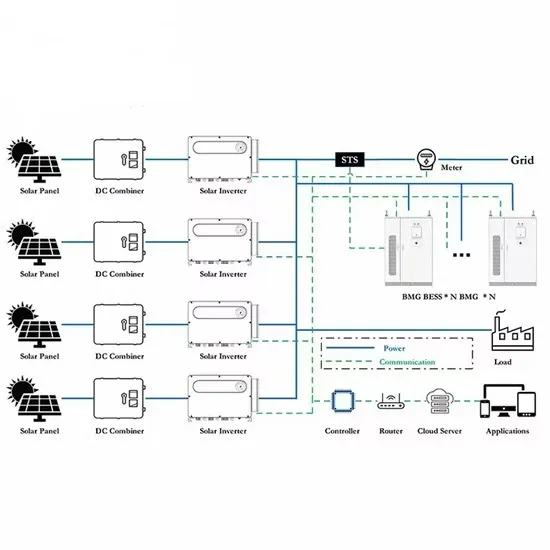

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.