Review and perspective of materials for flexible

Dec 1, 2020 · In this paper, we provide a comprehensive assessment of relevant materials suitable for making flexible solar cells. Substrate materials reviewed

Stiffness and fracture analysis of photovoltaic grade silicon plates

Oct 15, 2016 · In the photovoltaic (PV) domain most of the literature deals with the improvement of the electrical efficiency, by acting on some physico-chemical parameters. However, it is also

Flexible vs Rigid Solar Panels: Which is Better for

Nov 8, 2024 · The solar panels you see in home solar systems are almost always flat and rigid. Are you aware that there is another type of solar panel that

Modulation of elastic perovskites for flexible photovoltaics

To prevent the low conductivity of the incorporated materials, self-healing ionic conductive elastomers were incorporated into the perovskite films, which effectively repaired grain

Review and perspective of materials for flexible

Dec 1, 2020 · Thin-film flexible solar cells are lightweight and mechanically robust. Along with rapidly advancing battery technology, flexible solar panels are

Game-Changers for Flexible Perovskite Solar

Jan 1, 2025 · Elastomers are polymers known for their high elasticity and ability to undergo significant deformation before returning to their original shape,

Understanding Photovoltaic Cells and How They

Mar 26, 2025 · How photovoltaic cells convert sunlight into electricity using the photovoltaic effect. Learn about their structure, types, and benefits for clean

Effects of Extreme Weather Conditions on PV

Nov 17, 2023 · The results of the analysis show that existing PV systems are very resilient to extreme weather conditions. Utility-scale PV systems can usually

(PDF) Mechanical analysis of photovoltaic panels with

Aug 19, 2019 · The photovoltaic (PV) panels currently existed on market are a kind of laminated plate structure, which is composed of two stiff glass skins and a soft interlayer. Some of those

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · What Is the Difference Between Photovoltaic Module and Photovoltaic Panel? The difference between a photovoltaic module and a photovoltaic panel is their composition and

The elastic polymer solar cell that stretches like

Oct 15, 2024 · When tested, the new elastic organic photovoltaic demonstrated an initial conversion efficiency of 14.2%, exceptional elasticity, and record

Flexible Photovoltaic System on Non-Conventional

Mar 18, 2022 · In this research, elastic solar panels assisted by flexible photovoltaic systems (FPVs) were developed, fabricated, and analyzed on a 1 m2 scale. A flexible structure on a

Thermal Stress and Strain of Solar Cells in Photovoltaic

Feb 17, 2023 · Ulrich Eitner, Sarah Kajari-Schr ̈oder, Marc K ̈ontges and Holm Altenbach Abstract The long-term stability of photovoltaic (PV) modules is largely influenced by the module''s

Flexible vs. Rigid Solar Panels: A Comprehensive

Nov 26, 2023 · The rugged, durable polymer materials that encapsulate the photovoltaic solar cells in flexible panels render them inherently resistant to

Extreme Wave Impact on Elastic Photovoltaic Panels

Jan 16, 2025 · The generated cracks when waves impact photovoltaic panels affect their power generation efficiency and service life, but research on wave-impacted elastic photovoltaic

Photovoltaic Cell (PVC) | Definition, How It

Jul 25, 2022 · Photovoltaic Cell Efficiency Photovoltaic cells'' efficiency is measured using the "efficiency ratio", representing how much sunlight hits the

Mechanical analysis of photovoltaic panels with various

Jan 1, 2020 · The photovoltaic (PV) panels currently existed on market are laminated plate structures, which are composed of two stiff glass skins and a soft interl

(PDF) Stress Analysis of the Solar Cells in PV

Sep 24, 2020 · A simple analytical solution was proposed for stress evaluation of the solar cells. The present solution was then applied to the stress calculation

Thermal Stress and Strain of Solar Cells in Photovoltaic

Feb 17, 2023 · a stress increase in the back sheet towards the center of each solar cell. In the solar cells themselves the stress distribution is similar for all cells as it increases towards the

6 FAQs about [Are photovoltaic panel cells elastic ]

Can a photovoltaic material be used in flexible solar cells?

be used in flexible solar cells. In general, if a photovoltaic material can be can potentially be used in fabricating flexible solar cells. Several types of cation. In the following sections, we will discuss the fundamentals of for flexible solar cells. ef ficient flexible solar cells. (PECVD) and to a less degree chemical vapor deposition (CVD). The

Are solar panels as thick as spiderwebs?

Another team of scientists have developed solar panels as thick as spiderwebs. Specialists have created ultra-thin, flexible, and very efficient solar cells. The third part of the cell is the active elements that are engaged in the production of energy, and 2/3 of the cell is the polymer base .

What are photovoltaic materials?

A detailed examination of photovoltaic materials, including monocrystalline and polycrystalline silicon as well as alternative materials such as cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and emerging perovskite solar cells, is presented.

What is the future of flexible solar panels & photovoltaic materials?

Bridging the energy gap through innovative solar technologies has the potential to empower communities and contribute to global energy equity. In conclusion, the future of flexible solar panels and photovoltaic materials is teeming with possibilities and challenges that require multidisciplinary collaboration and innovative thinking.

What are flexible thin-film solar panels?

Along with traditional mono- and polycrystalline solar panels on a rigid frame, flexible thin-film panels are widely used. The technological process of creating thin-film solar cells formed on flexible substrates is relatively simple, and minimal energy consumption significantly reduces the cost of manufacturing “flexible” solar cells.

What is a flexible solar panel?

The presence of a cylindrical shape means resistance to strong winds, with gusts up to 200 km/h. The first large roll-up flexible solar array was used in NASA’s Solar Array Flight Experiment (SAFE) program. The first foldable flexible solar panel was installed on the Communications Technology Satellite (CTS) .

Update Information

- Photovoltaic panel specifications dimensions and wattage

- Price of a flexible photovoltaic panel

- Tashkent photovoltaic panel greenhouse breeding manufacturer

- 25kw photovoltaic panel power generation

- Port Louis polycrystalline photovoltaic panel price

- The photovoltaic panel with the highest power conversion rate

- Bolivia rooftop photovoltaic panel installation

- BESS a photovoltaic rooftop panel in Central Europe

- What is the output voltage of a 550w single crystal photovoltaic panel

- 5 volt photovoltaic solar panel

- Paraguay EK photovoltaic panel manufacturer

- Ukrainian photovoltaic panel custom manufacturer

- Wellington grid-connected photovoltaic panel manufacturer

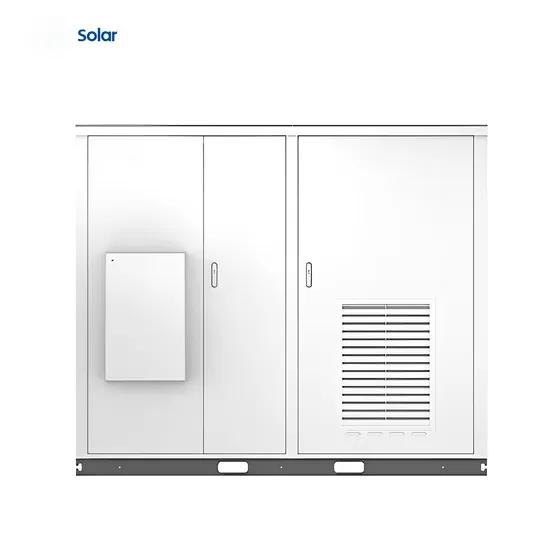

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.