80V Lithium-ion Forklift Battery Datasheet

Oct 11, 2022 · We select outer box and inner box combination solutions to design our forklift lithium batteries, inter-box for batteries, outer-box for dimension and additional weight. The

How to Choose the Right Forklift Battery Pack for Your Needs

Nov 13, 2024 · Choosing the right forklift battery pack is crucial for efficient operations in material handling. This guide will help you understand the manufacturing process, key features, and

Lithium-Ion vs. Lead-Acid Forklift Batteries:

Aug 18, 2025 · Compare lithium-ion and lead-acid forklift batteries in terms of cost, performance, maintenance, and lifespan. Find out which battery is right

Lithium-Ion Battery Packs for Electric Forklifts:

Aug 16, 2025 · Upgrading to lithium-ion battery packs for electric forklifts is a strategic investment decision that can help you realize benefits of forklift

Lithium-Ion Batteries: The Ultimate Upgrade for

Aug 30, 2024 · Lithium-ion batteries are a great choice for electric forklifts because of their high efficiency, long lifespan and maintenance free nature.

Electric Forklift Lithium Battery Pack

Mar 27, 2025 · Name: Cold Chain Logistics Center Electric Forklift Lithium Battery Pack Project. Product: Customer Customization. Features: Extreme Temperature Operations: Operating in

Lithium 80V 400AH Rechargeable LiFePO4 Battery Pack For

High quality Lithium 80V 400AH Rechargeable LiFePO4 Battery Pack For Toyota Hangcha Komatsu Heli Electric Forklift Truck from China, China''s leading product market 400AH

BSLBATT 24 volt battery electric forklift battery pack

Jul 26, 1997 · 24V 460Ah electric forklift battery pack adopts lithium iron phosphate battery cells with high safety, long cycle life and excellent thermal stability. It supports fast charging, 1-2

What Are Forklift Battery Sizes and Configurations?

Sep 23, 2024 · How Are Forklift Batteries Configured? Forklift batteries are configured in series or parallel arrangements to achieve the desired voltage and capacity. Series configurations

48 volt forklift batteries for Electronic Appliances

48 volt forklift batteries are essential power sources designed to provide reliable and efficient energy for electric forklifts. These batteries play a pivotal role in the material handling industry,

Electric Forklift Lithium Battery Pack

Mar 27, 2025 · Name: Cold Chain Logistics Center Electric Forklift Lithium Battery Pack Project Product: Customer Customization Features: Extreme Temperature Operations: Operating in

New lithium batteries for electric forklifts

Jan 23, 2019 · New lithium batteries make electric forklifts an even more viable alternative to diesel vehicles. Electric forklifts have been around for years, but

Lithium Forklift Batteries

Forklift Lithium Batteries More than 30,000 drivers choose BSLBATT lithium batteries. We provide more than 950 models of Lithium-ion batteries for electric industrial trucks. With 3000 cycle life,

BSLBATT Industrial Lithium Batteries

Jul 26, 1997 · Forklift Battery Specifications: Capacity, Size and Weight BSLBATT® has several standard battery types by voltage (24V, 36V, 48V, 72V, 80V, 96V, 121.6V, 144V) and different

What Are Lithium Forklift Batteries?

May 26, 2025 · Lithium forklift batteries are advanced power units using lithium-ion cells (e.g., LiFePO4) to energize electric forklifts in warehouses and logistics. They outperform lead-acid

Austria electric warehouse truck lithium battery pack

Electric Forklift Narrow Aisle Warehouse Truck LPG Forklift Diesel Forklifts Li-ion Tractor Heavy-duty Products Products Video; Introducing the HELI G3 Series 4-5t Lithium Battery Forklift Truck!

36 V Lithium-Ion Battery for Forklift & Reach

4 days ago · Sit-down and stand-up counterbalanced forklifts in warehouse or distribution centers 36 V lithium-ion power solutions for dock stockers Power

Find The Best Forklift Batteries & Chargers on Sale

Jun 9, 2022 · Lithium-Ion battery technology is quickly becoming the far superior choice of battery for specialised high usage electric forklift applications over all

6 FAQs about [Austria electric forklift lithium battery pack]

Are electric forklifts a viable alternative to diesel vehicles?

New lithium batteries make electric forklifts an even more viable alternative to diesel vehicles. Battery Technology: Lead Acid vs Li-ion.

How many batteries do you need in a multi-shift operation?

One, there’s no need to have several batteries in a multi-shift operation, one is enough because it can be recharged during the shift. Two, the new battery lasts for up to 4,000 cycles, compared to lead-acid battery’s 1,500 cycles. “The battery efficiency is 95 percent, compared to 70 with the lead-acid battery.

Are Kalmar electric forklifts a viable alternative to diesel vehicles?

• Additional batteries required for multi-shift operation. New lithium batteries make Kalmar electric forklifts an even more viable alternative to diesel vehicles.

Are lithium-ion batteries better than lead-acid batteries?

In a couple of years, the lithium battery will be much more cost-efficient than lead-acid batteries,” he adds. Worth noting about the Lithium-ion batteries is that there is a residual value to take into account, a used battery for one player will be a valuable battery for another one.

Will Kalmar's new lithium-ion battery change the world?

The demand for them is increasing all over the world – and Kalmar is at the forefront of that development, with its new lithium-ion battery and more than 30 years of experience in the electrification field. “We’ve had our lead-acid batteries for decades, but the new Li-ion is going to change everything,” says Johansson.

Does Kalmar offer a forklift?

“Another important factor is the fact that Kalmar can now offer forklifts up to 18 ton, and not just the 5-9 forklifts we had earlier.” Furthermore, Kalmar is fully committed to support customers with their journey towards eco-efficient cargo and material handling.

Update Information

- Electric measurement of peak discharge of lithium battery pack

- Argentina electric stacker lithium battery pack

- Tanzania electric sanitation vehicle lithium battery pack

- Lithium battery pack new energy

- Sales of lithium battery pack manufacturers

- 11V lithium battery pack

- Discharge capacity of lithium battery pack

- Lithium battery pack power module

- Helsinki lithium battery pack series connection

- Nanya lithium battery pack

- Ethiopian flashlight lithium battery pack

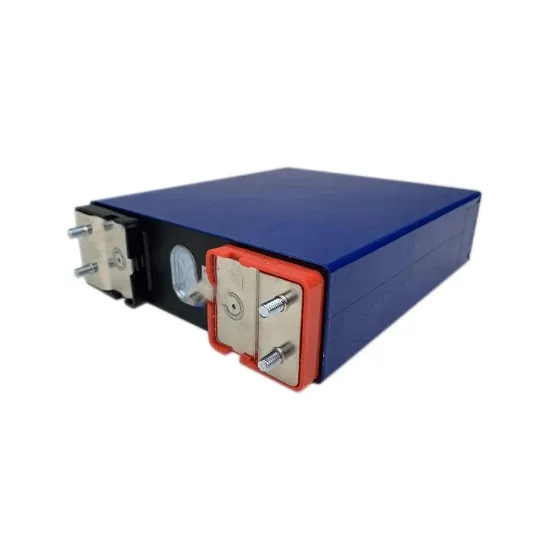

- American large monomer lithium battery pack

- Cambodia Lithium Battery PACK Factory Introduction

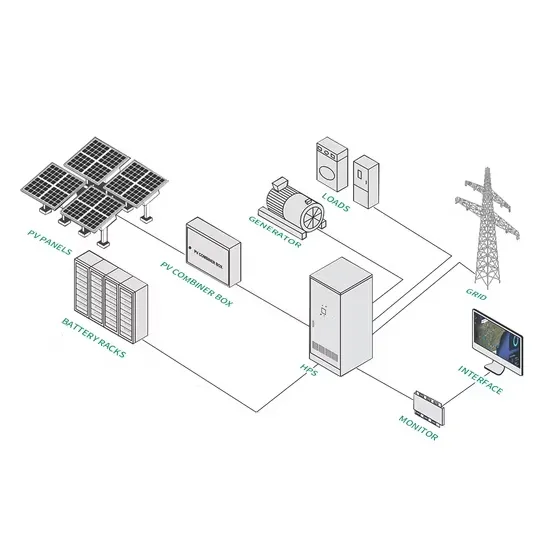

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.