Wind Power Generation and Modeling | part of Power System

Nov 9, 2023 · This chapter provides a reader with an understanding of fundamental concepts related to the modeling, simulation, and control of wind power plants in bulk (large) power

Aggregator control of battery energy storage in wind power stations

Oct 1, 2024 · Battery systems that provide multiple functions, such as frequency control system services and wind power regulation, can participate in the aggregator scheme by assigning a

Wind Power Plants Control Systems Based on SCADA System

Mar 5, 2021 · The SCADA system enables operators to monitor, control, and record wind power plant data from a remote location called a central control station [1, 2]. It consists of three main

Power electronics in wind generation systems

Mar 26, 2024 · We then highlight the role of power electronics for wind power systems, including their advanced control, and discuss issues from the power system-level perspective that relate

What Are the Different Types of Control Systems in Wind

Below we have mentioned six main types of wind energy control systems for your reference. In each type, you will get a quick overview of the system, how it works, and its importance. 1.

Grid Integration of Wind Energy Systems: Control Design, Stability

Jan 1, 2017 · This chapter presents a comprehensive coverage on the modeling and control design of variable speed wind energy–conversion systems (WECSs). Different

Topologies and Control Technologies of Wind Energy Conversion System

Apr 24, 2025 · The aim of this review paper is to serve as an important resource for professionals, engineers and researchers in the wind systems field by offering a concise review of topologies

Wind Power Plants Control Systems Based on SCADA

Sep 13, 2023 · SCADA serves as the primary interface between the wind power plant operator and the wind farm equipment [1–4]. It allows integrating all the info about WTGs,

Analysis of energy control system in wind farm

Therefore, it is necessary to use an energy control system in new energy stations to regulate the active power of the new energy station. By using an energy management system, stable and

WIND POWER PLANT AUTOMATIC CONTROL SYSTEM

Feb 10, 2022 · The control system is used in various parts and subsystems of a wind power system for various purposes [1].The wind power station''s control system is mainly divided into

A comprehensive review of wind power integration and

May 15, 2024 · As a result, it would be advantageous to combine wind power and energy storage systems to build a real power station or a virtual power station that could supply the industries

Fuzzy Model of Wind Turbine Control | SpringerLink

Jul 17, 2019 · the second—active system works in such a way, that the pitch angle of blades in relation to the wind is in such a position, which will cause the rotor braking at the excessive

Wind Electrical Systems (WES): Lecture Notes:

Feb 21, 2021 · 1.12 Wind Turbine Control Systems equire certain control systems. Horizontal-axis wind turbines have to be oriented to face the wind. In high winds it is desirable to reduce the

Wind power generation: A review and a research agenda

May 1, 2019 · Wind power also plays an important role by reducing greenhouse gas emissions and thus attenuating global warming. Another contribution of wind power generation is that it

Frequency control of power system with solar and wind power stations

Aug 14, 2017 · In recent years, environmental problems are being serious and renewable energy has attracted attention as their solutions. However, the electricity generation using the

WIND POWER PLANT AUTOMATIC CONTROL SYSTEM

Feb 10, 2022 · The article discusses issues aimed at creating an automatic control system for a sailing wind power station, which is designed to increase the productivity, ease of operation

An overview of control techniques for wind turbine systems

Nov 1, 2020 · This review paper presents a detailed review of the various operational control strategies of WTs, the stall control of WTs and the role of power electronics in wind system

6 FAQs about [Wind power station control system]

What are wind turbine control solutions?

The wind turbine control solutions embrace automation systems for wind turbines and wind farms. A broad range of wind turbine control systems can be used for off-shore and/or on-shore wind power generation and wind farm management. These solutions assist wind turbines and farms to operate smoothly and cost-effectively.

How does a wind farm control center work?

The wind farm control center takes power dispatch commands from the system operator. Consequently, distributes power reference levels to individual wind generator controllers, which in turn facilitates the wind farm to keep output power within the dispatch order from the system operator [16, 17, 18, 19].

How a wind turbine control system works?

The control system, together with the integrated wind turbine control unit and SCADA technology, can help manage both individual wind turbines and the wider wind farm resources to help reduce turbine generator downtime and increase availability. The wind turbine control solutions embrace automation systems for wind turbines and wind farms.

What is wind control center?

These individual turbines, substations, meteorological stations, and other wildlife monitoring systems are connected to the central control room in Wind Control Center. It provides visibility to the operator to oversee the behavior of all wind turbines on all wind farms.

What is wind farm control design?

Wind farm control design is a recently new area of research that has rapidly become a key enabler for the development of large wind farm projects and their safe and efficient connection to the power grid. A comprehensive review of the intense research conducted in this area over the last 10 years is presented.

What is a classification of wind farm controllers?

A classification of wind farm controllers. Classification of wind farm control concepts adopted for the review. In , EVM is used to study the effects of down-regulating upwind turbines using pitch control. A power gain of about 4.1% is achieved at a row of ten turbines with a spacing of 4 D.

Update Information

- Wind power station control system

- Airport materials outdoor base station wind power

- British communication base station wind power installation

- What are the base station wind power cabinets

- Power supply communication base station wind power

- How long will the wind power of the communication base station be disconnected if no one maintains it

- Base station wind power supply equipment installation

- Podgorica Outdoor Wind Power Base Station Company

- Nassau Communication Base Station Wind Power Construction Company

- How many companies make up the communication base station wind power

- Modern communication base station wind power construction

- Basseterre Wind and Solar Energy Storage Power Station

- Indoor base station wind power communication

Solar Storage Container Market Growth

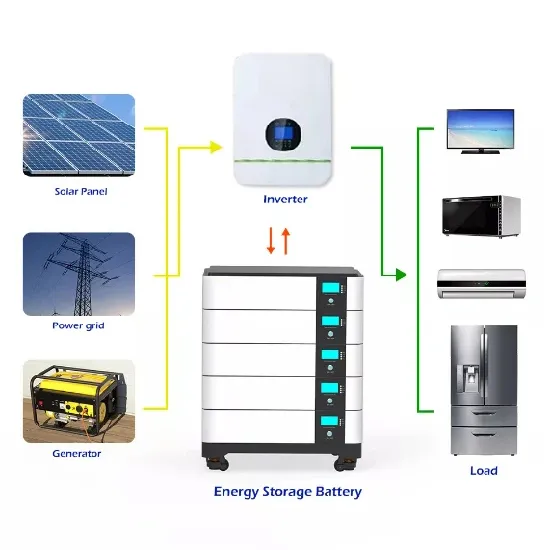

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.