Company hopes Boston gets a charge out of its plans for a large battery

Jun 11, 2024 · A Colorado company that builds industrial-sized battery systems for use in electrical grids says it will soon file plans to build a two-story "battery energy storage system"

BESS Projects – CME Energy

4 days ago · Electric Ave Energy Center is a 185MW Battery Energy Storage System that CME is jointly developing with its Partners Hecate Energy and Flatiron Energy in Brighton, MA. The

Boston-Power Announces Plans To Build One of the World''s

May 31, 2009 · Enabling energy storage to continue to flourish in Massachusetts, state officials are working closely with Boston-Power to pursue state and federal financial incentives that will

Company announces nearly $712 million project

Nov 16, 2024 · A battery manufacturer has selected Kentucky for a nearly $712 million project to produce industrial-sized batteries used to store and distribute

Form Energy Unveils Chemistry of Multi-day Storage Battery

Jul 22, 2021 · Announces Series D with Leading Strategic Partner, Accelerating Pathway to Commercialization of First Energy Storage Product Boston, MA – July 22, 2021 – Form

Factorial Energy to open new solid-state EV battery

Factorial Energy, a developer of solid-state battery technology for electric vehicle (EV) applications, will establish a new advanced manufacturing facility in the Boston suburb of

New Solid-State EV Battery Factory Opens In Massachusetts

Oct 23, 2023 · The latest sign of a domestic nuts-and-bolts revival comes from the US startup Factorial Energy, which is launching a new solid-state EV battery factory in its home state of

Canadian startup secures $15M to repurpose EV batteries

Aug 9, 2025 · A Canadian startup has secured $15M in funding from Amazon and other investors to repurpose EV batteries, extending their lifespan and reducing waste. By giving used

Pure Lithium Receives $300M Letter of Interest from the

Apr 22, 2025 · Pure Lithium Corporation, a disruptive Boston-based vertically integrated lithium metal battery technology company, is pleased to announce it has received a

Factorial Energy opens solid-state battery

Oct 25, 2023 · Factorial Energy, a developer of solid-state battery technology for EV applications, has opened a new battery manufacturing facility in the Boston

Boston Energy Storage: Powering the City''s Future One Battery

Let''s face it - when you think of Boston, you probably picture historic cobblestone streets, passionate sports fans, and revolutionary energy storage solutions? Believe it or not, the city

Factorial Energy''s new manufacturing facility

Oct 24, 2023 · Factorial Inc., a developer of solid-state battery technology for electric vehicle (EV) applications, announced the opening of its new battery

What is Battery Energy Storage System (BESS)

5 days ago · The operating principle of a battery energy storage system (BESS) is straightforward. Batteries receive electricity from the power grid, straight from

Tata Group to set up a Battery Gigafactory in the

Jul 19, 2023 · Tata Sons will build a 40GW battery cell gigafactory in the United Kingdom (UK). The investment, of over £4 billion, will deliver electric mobility

Massachusetts, New England States Selected to Receive

Aug 6, 2024 · States selected to receive highly competitive funds from the U.S. Department of Energy''s Grid Innovation Program for transmission upgrades in Southeastern Massachusetts

A battery storage facility is being proposed in a

Jul 11, 2025 · What is a battery energy storage system? The lithium-ion batteries in phones, laptops, and wearable electronics are the basis of the technology

Councilors to look into large battery storage systems

Oct 9, 2024 · The City Council agreed today to look into the environmental and safety issues related to plans for at least two industrial-sized electricity-storage plants, one on the aptly

FREYR Battery establishes Technology Center in Boston

Aug 23, 2022 · FREYR Battery has announced that it has opened its first U.S.-based technology center in Boston by the company''s expansion strategy. Listed on the New York Stock

USA: Factorial Energy opens solid-state battery development

Oct 24, 2023 · Factorial Energy, the US developer of solid-state battery cells backed by Mercedes-Benz, Stellantis and Hyundai-Kia, has opened its manufacturing facility in Methuen,

6 FAQs about [Boston Energy Storage Battery Source Factory]

What is the largest solid-state battery assembly line in the US?

With a capacity of 200 MWh, it is said to be the largest solid-state battery assembly line in the US to date. Factorial Energy, the US developer of solid-state battery cells backed by Mercedes-Benz, Stellantis and Hyundai-Kia, has opened its manufacturing facility in Methuen, a Massachusetts suburb of Boston.

Will Massachusetts help Boston-power build a new energy storage facility?

Enabling energy storage to continue to flourish in Massachusetts, state officials are working closely with Boston-Power to pursue state and federal financial incentives that will help the company to fulfill its plans of building the Auburn facility.

Can solid-state batteries improve materials recovery & recycling?

Part of the allure of solid-state batteries is the potential for improving materials recovery and recycling. Factorial is working that end of the solid-state EV battery room as well. In June, the company announced a lithium recycling research partnership with the Korean firm Young Poong, which specializes in non-ferrous metal smelting and refining.

Where is factorial's new EV battery factory located?

Earlier this month Factorial announced plans for a new battery R&D facility to be located in Massachusetts, and on October 23 the company is celebrating the official opening ceremony for its new solid-state EV battery factory, located in the Boston-area suburb of Methuen.

Where is the world's most advanced battery manufacturing facility located?

Boston-Power, Inc. announced that the company is working to build what it describes as one of the world’s most advanced battery manufacturing facilities in Auburn, Massachusetts.

Does factorial have a solid-state EV battery?

Into this mix comes Factorial with a new solid-state EV battery called FEST® (Factorial Electrolyte System Technology). CleanTechnica took note of the company back in 2021, when the auto makers Daimler and Stellantis signaled they were interested in the technology. Don’t get too excited just yet.

Update Information

- Democratic Congo energy storage low temperature lithium battery factory

- Huawei Pristina Energy Storage Battery Factory

- West Africa Energy Storage Power Source Factory

- Andorra New Energy Storage Battery Factory

- Juba Energy Storage Battery Factory

- Dominica Energy Storage Power Source Factory

- Mauritius Energy Storage Cabinet Battery Factory

- Paris Energy Storage Low Temperature Lithium Battery Factory

- Fiji Energy Storage Cabinet Source Factory

- Ghana Energy Storage Low Temperature Lithium Battery Factory

- Huawei Asia Energy Storage Battery Factory

- Thailand Energy Storage Power Source Factory

- Brunei lithium battery energy storage cabinet factory is running

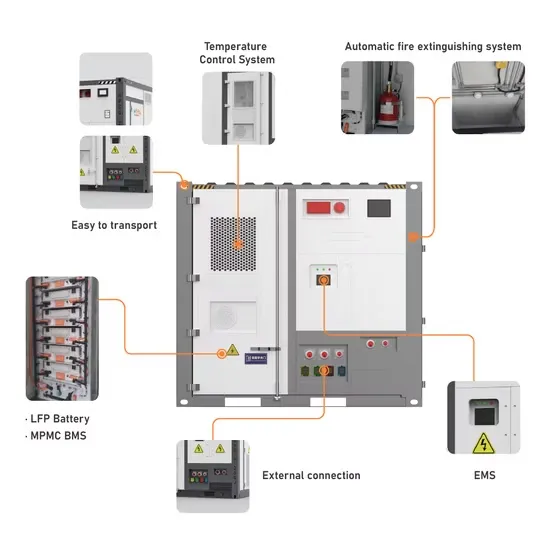

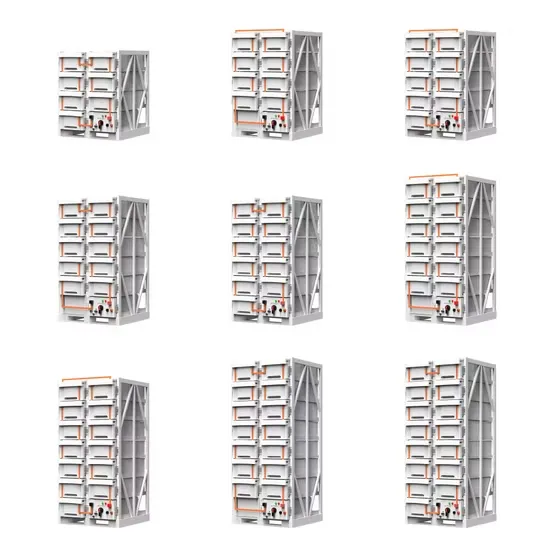

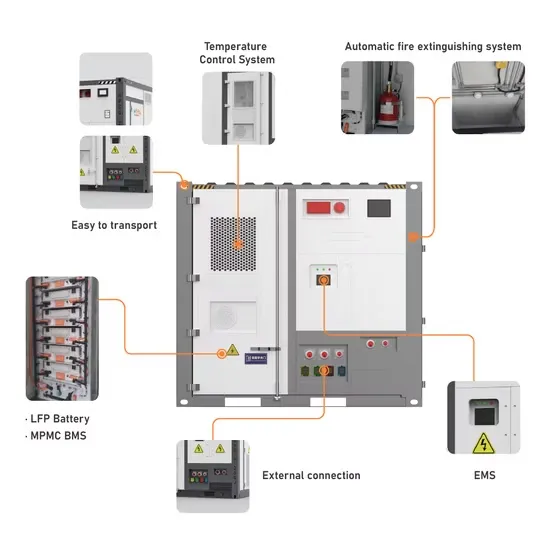

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

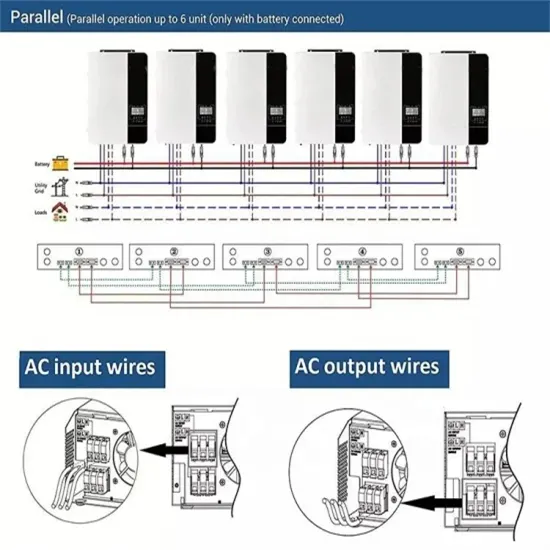

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.