Predictive-Maintenance Practices For Operational Safety

Oct 26, 2020 · If the engineers identify a real anomaly, they place the offending battery rack out of service until the module is replaced. In summary, predictive maintenance has allowed NEC to

基于少测点数据驱动的大规模锂电池模组温度实时预测

May 23, 2024 · 本文尝试通过基于数据驱动的反问题方法,利用少量测点的温度数据反映大规模电池模组的实时温度情况. 将基于降阶模型的多模态处理方法——Gappy POD算法引入到大规模

Simplified Battery Pack Modeling Considering Inconsistency

Jul 31, 2020 · With the development of battery technology, large-scale battery applications are increasing. In order to obtain a higher current and voltage level and improve the overall energy

The sensitive detection of the early-stage internal short

Mar 19, 2025 · Energy, 2024, vol. 304, issue C Abstract: The internal short circuit (ISC) is one of the main causes of thermal runaway in batteries. Facing the current fast charging scenario of

Methods of photovoltaic fault detection and classification: A

Nov 1, 2022 · Specific PV fault detection and classification techniques are also enumerated. A possible direction for research on the PV fault detection and classification, such as quantum

Battery energy storage system modeling: A combined

Feb 1, 2019 · Battery pack modeling is essential to improve the understanding of large battery energy storage systems, whether for transportation or grid storage. I

Design of non-equilibrium photovoltaic High-Operating-Temperature

Apr 4, 2023 · Non-equilibrium photovoltaic HgCdTe detector with a P + νN + structure has been demonstrated to work at high temperature, in which carriers were swept out in a non

Online lithium-ion battery intelligent perception for

Jul 24, 2023 · Although the internal temperature detection of lithium-ion batteries is more reliable than surface temperature detection, surface temperature detection utilizing a thermographic

High-resolution thermal monitoring of lithium-ion batteries

Dec 20, 2024 · Our proposed distributed fiber optic sensor leverages advanced optical techniques to achieve spatial resolution of 1.4 cm and measurement uncertainty of 0.38 °C. For precise

Efficient energy storage technologies for photovoltaic systems

Nov 1, 2019 · For photovoltaic (PV) systems to become fully integrated into networks, efficient and cost-effective energy storage systems must be utilized together with intelligent demand side

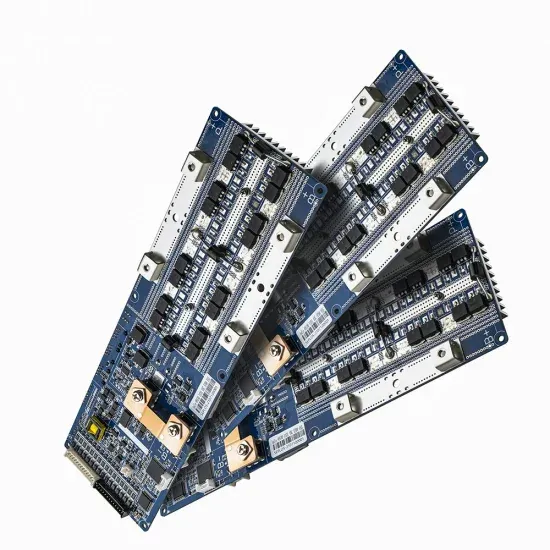

Battery module active balancing-low temperature self

Jun 1, 2025 · In order to address the limitations of traditional battery module balancing and low-temperature self-heating systems, which are often associated with

Efficient photovoltaics integrated with innovative Li-ion batteries

Mar 25, 2025 · To simultaneously test both current and new types of whole photovoltaics (PV) and innovative Li-ion batteries (LIBs) at extreme temperatures (180 °C to -185 °C) in the research

An Enhanced Model-Based Algorithm for Early Internal

By measuring the surface temperature and terminal voltage of the battery cell, the proposed extended Kalman filter (EKF) model-based detection method can successfully detect the ISC

Performance Optimization of Hg1-xCdxTe Photovoltaic

Sep 30, 2024 · In this study, we utilize compositional gradients and array electrode designs to make better trade-offs among dark current, responsivity, and saturation characteristics of

Assessing high-temperature photovoltaic performance for solar

Aug 1, 2018 · We demonstrate that (1) the use of highly concentrated sunlight markedly diminishes photovoltaic - as well as thermal - efficiency losses at high temperature, and (2) the

Online Sensorless Temperature Estimation of Lithium-Ion Batteries

Mar 1, 2024 · Owing to the nonnegligible impacts of temperature on the safety, performance, and lifespan of lithium-ion batteries, it is essential to regulate battery temperature to an optimal

Robust integral super-twisting controller for enhanced photovoltaic

Dec 1, 2024 · The PV/battery/supercapacitor-based DC microgrid under PV- generating step fluctuations considered as simulation objective. The temperature at 25 °C and the load

Research on the impact of high-temperature aging on the

Dec 1, 2023 · Similarities arise in the thermal safety evolution and degradation mechanisms for lithium-ion batteries undergoing cyclic aging and calendar aging. Employing multi-angle

Simplified silicon recovery from photovoltaic waste enables high

Aug 1, 2023 · This approach led to an impressive recovery rate of 98.9% with a high purity of 99.2%, as determined by X-ray fluorescence and Inductively-coupled plasma optical emission

A diagnostic model for lithium plating in lithium-ion batteries

Mar 11, 2025 · Lithium plating happens when batteries are charged at high C-rates or low temperatures, potentially damaging their capacity and compromising safety. Diagnosing

The viability of solar photovoltaic powered off-grid Zero

Mar 1, 2021 · With strongly decreasing prices of photovoltaics (PV) and battery storage in the past decade, together with incentives for modular construction in China, shipping containers have

Online core temperature estimation method for lithium-ion batteries

Jan 30, 2025 · Online monitoring of the core temperature in Lithium-ion batteries (LIBs) is essential for effective thermal management and risk prevention. Throughout the lifecycle of

A simplified approach to modeling temperature dynamics in photovoltaic

Aug 1, 2024 · This paper presents a simplified theoretical model for analyzing the temperature dynamics of photovoltaic (PV) modules. The model is built on an energy balance approach,

Ultra high temperature latent heat energy storage and

Jul 15, 2016 · A conceptual energy storage system design that utilizes ultra high temperature phase change materials is presented. In this system, the energy is stor

基于少测点数据驱动的大规模锂电池模组温度实时预测

May 23, 2024 · Proper thermal management ensures uniform heat distribution, which is essential for optimizing efficiency, safety, and reliability. However, obtaining comprehensive real-time

HeatMate-Photovoltaic Battery Storage-Mobile Container

Photovoltaic phase-change cold storage mobile container is a revolutionary cold chain product, combining HeatMate''s self-developed nano-eutectic phase change energy storage materials,

Preparation of a Stacked Grid Electrode for Intelligent Temperature

Currently, the methodology employed for monitoring the operational status of photovoltaic components through additional temperature-sensing elements is beset by considerable

Photovoltaic Phase Change Cold Storage Mobile Cold

Photovoltaic Phase Change Cold Storage Mobile Cold Storage Photovoltaic phase-change cold storage mobile container is a revolutionary cold chain product, combining HeatMate''s self

Online Sensorless Temperature Estimation of Lithium-Ion Batteries

Mar 1, 2024 · As such, developing sensorless temperature estimation is of paramount importance to acquiring the temperature information of each cell in a battery system. This article proposes

6 FAQs about [Simplified high temperature detection of photovoltaic container batteries]

How can sensorless temperature estimation be used in a battery system?

As such, developing sensorless temperature estimation is of paramount importance to acquiring the temperature information of each cell in a battery system. This article proposes an estimation approach to obtain the cell temperature by taking advantage of the electrothermal coupling effect of batteries.

Can optical fiber sensors detect internal temperature in a lithium ion battery?

The maximum relative sensitivity of the optical fiber sensor was 1.62% K −1 at 293 K and the temperature detection limit was within ±0.5 °C. By embedding the prepared sensor in a Li-ion battery, the proof of concept was obtained for monitoring the internal temperature of a battery with upconversion nanoparticles (UCNPs).

How important is temperature monitoring in battery thermal management?

Temperature monitoring plays a fundamental role in battery thermal management, yet it is still challenged by limited onboard temperature sensors, particularly in large-scale battery applications.

Can upconversion nanoparticles monitor the internal temperature of a battery?

By embedding the prepared sensor in a Li-ion battery, the proof of concept was obtained for monitoring the internal temperature of a battery with upconversion nanoparticles (UCNPs). A larger temperature variation was observed under a higher discharge rate.

How does a closed-loop observer measure battery temperature?

A closed-loop observer is then designed based on this coupled model and the extended Kalman filter to estimate the battery temperature by merely using the voltage measurement as feedback.

Can Brillouin optical correlation domain analysis improve battery temperature distribution monitoring?

This paper presents the Brillouin optical correlation domain analysis system as an innovative solution for real-time temperature distribution monitoring during battery operation. Our proposed distributed fiber optic sensor leverages advanced optical techniques to achieve spatial resolution of 1.4 cm and measurement uncertainty of 0.38 °C.

Update Information

- How high a temperature can photovoltaic glass withstand

- Spanish high quality photovoltaic folding container wholesale

- Myanmar temperature controlled photovoltaic folding container wholesale

- Energy storage container photovoltaic area

- Lead-acid batteries for communication base stations and photovoltaic batteries

- Vientiane high temperature resistant battery cabinet production

- High calcium stone for photovoltaic glass

- Athens has a high proportion of photovoltaic energy storage capacity

- Price of photovoltaic integrated container

- Tripoli photovoltaic folding container wholesale

- Relationship between photovoltaic panel power and temperature

- Energy storage container solar photovoltaic module factory photothermal equipment

- Maputo High Temperature Solar System Design

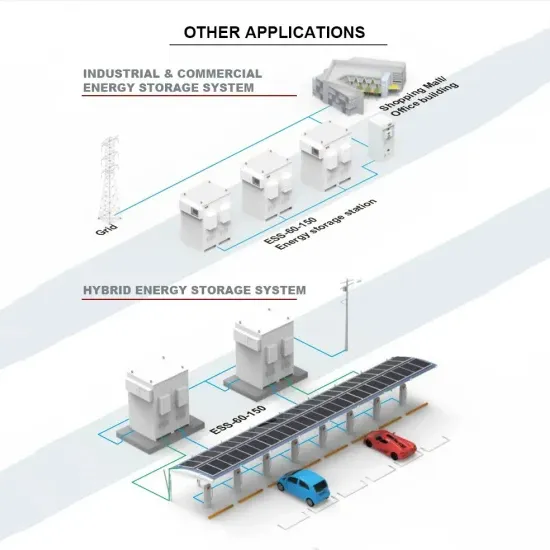

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.