Measuring the Insulation Resistance of PV Strings to the

Before connecting PV strings to the inverter, ensure that the insulation resistance of each PV string to the ground is normal. The following figure shows the measuring method. Connect the

How to distinguish positive and negative in photovoltaic

Most solar panels will have the polarities of the terminals labeled. If the polarities are not labeled, two methods can be used to check. The first is A PV string circuit without a ground fault will

Photovoltaic panel string connection line tutorial

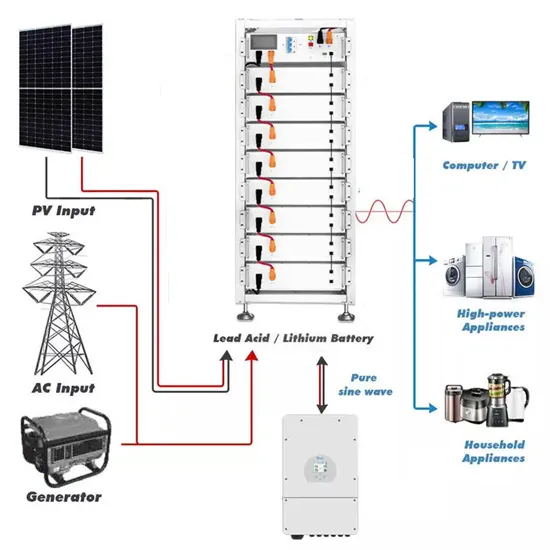

Parallel connection of photovoltaic panels is a method in which all the positive terminals of the panels are connected together, just like all the negative terminals. the performance of one

Solis Seminar 【Episode 55】: Using the piecewise method to check the PV

Sep 15, 2023 · The method is as follows: a) Disconnect the intermediate PV model terminals of the same PV string to form two smaller PV strings. b) Measure the PV+ and PV- of small PV

Dangerous voltage between positive and ground (structure)

Aug 18, 2025 · I checked the negative wire for any chaffing or anywhere that could cause a ground fault and found nothing. I then disconnected the -ve from the inverter and the voltage

Solar Inverter String Design Calculations

Oct 12, 2023 · Solar Inverter String Design Calculations The following article will help you calculate the maximum / minimum number of modules per series string when designing your

Impact of shading heaviness on voltage, current and power

Jan 1, 2025 · Nonetheless, the PV array''s modules must contend with a number of difficulties, including fluctuations in solar radiation. A photovoltaic system is highly susceptible to partial

Test PV Strings with MCIs

Apr 3, 2025 · The following tests are performed on each PV string to confirm the PV wiring has been installed correctly and the array is functioning as expected: Verify PV String Polarity:

How to distinguish positive and negative in photovoltaic

A PV string circuit without a ground fault will have open circuit voltage (Voc) between positive and negative conductors. It will have zero volts from positive to ground and from negative to

Photovoltaic panel string voltage measurement

know the required voltage from the PV array. PV array open-circuit comes with a female and a male MC4 connector. Usually, the female MC4 connector stands for the negative terminal, and

Solar Panel Wiring: Connecting Solar Panels in

Dec 6, 2024 · The connection of solar panels is an important phase in the design of a photovoltaic system, as it directly affects the system''s performance and

How to read the photovoltaic panel string installation

The "solar panel string" is the most basic and important concept in solar panel wiring. This is simply several PV modules wired in series or parallel. Solar panels feature positive and

Negative current after photovoltaic panels are

The positive wires are connected to a positive connector within a combiner box, and the negative wires are connected to the negative connector. When multiple panels are wired in parallel, it is

Photovoltaic panel string open circuit voltage test

Jun 15, 2020 · Example -- Module Open-Circuit Voltage. A PV module, or a string of series-connected modules, has a rated open-circuit voltage that is measured (and labeled on the

Understanding PV Arrays and PV Strings: Key

Apr 15, 2025 · the difference between PV strings (a series of panels) and PV arrays (a combination of multiple strings) is critical to designing efficient solar

Solar panel wiring basics: An intro to how to

Oct 15, 2019 · Solar panel wiring (aka stringing), and how to string solar panels together, is a fundamental topic for any solar installer. You need to understand

Photovoltaic panel string voltage measurement

As the photovoltaic (PV) industry continues to evolve, advancements in Photovoltaic panel string voltage measurement have become critical to optimizing the utilization of renewable energy

Novel Solar-Cell String Wiring of Photovoltaic Module

Sep 11, 2024 · In terms of common wiring for solar-cell string, the positive string and negative string are arranged side by side and connected in series, as illustrated in Fig. 5.2a. Based on

Photovoltaic panel string diagram

The "solar panel string" is the most basic and important concept in solar panel wiring. This is simply several PV modules wired in series or parallel. Solar panels feature positive and

Novel Solar-Cell String Wiring of Photovoltaic Module

Sep 11, 2024 · The induced voltage polarity of the middle string is reversed by crossover wiring among these strings. To keep the output voltage of PV panel unchanged, the solar-cell strings

WHAT IS THE VOLTAGE OF A PHOTOVOLTAIC PANEL

What is a solar panel string calculator? Now,let us learn what is a solar panel string calculator. The maximum string sizeis the greatest number of PV modules that can be linked in series

Photovoltaic panel string open circuit voltage test

Jun 15, 2020 · For checking the voltage of PV modules connected in series. Check the operation and installation of control devices such as relay switches and circuit breakers. Test the

Amps from PV string confusing on multimeter

May 8, 2022 · When I check each of my 445w panels independently I get a nominal dc voltage and reasonable amps. When I put them in a series string the voltage adds as anticipated but

How to measure the positive and negative poles of

In this string of 16 modules, each with a Voc of 53.82 VDC, we measure 861.12 VDC, the PV string circuit open circuit voltage (16 x 53.83 = These PV panels are extremely expensive so

6 FAQs about [Voltage negative of photovoltaic panel string]

What happens if a PV module has a negative voltage potential?

When the so-called floating grounding string is used (the positive and also the negative pole of the string are not earthed) a negative voltage potential causes the leakage currents from the PV cells through the sandwich structure of the PV module into the grounded frame.

Do solar panels have positive and negative terminals?

Solar panels feature positive and negative terminals. Wiring solar panels in series means wiring the positive terminal of a module to the negative of the following, and so on for the whole string. This wiring type increases the output voltage, which can be measured at the available terminals.

What is a solar panel string?

The “solar panel string” is the most basic and important concept in solar panel wiring. This is simply several PV modules wired in series or parallel. Solar panels feature positive and negative terminals. Wiring solar panels in series means wiring the positive terminal of a module to the negative of the following, and so on for the whole string.

Are PV modules at the highest negative potential?

The claim that the most affected PID modules are at the highest negative potential in the PV plant string is wrong. The extent of PID in the negative part of string is random and PV modules performance cannot be predicted in advance. It is not possible to precisely determine the magnitude of the negative voltage required to initiate the PID. 1.

Why do PV cells have a negative electric field?

The resulting negative electric field between the aluminum frame and the cells accelerates the movement of the positive ions from the cover glass of the PV module through the sandwich structure to the PV cells, where they can cause a decrease of efficiency [ 1 ].

Is PV module degradation dependent on PV cells?

Considering that all PV modules in the string are made from the same materials, these results may lead to the conclusion that the PV module degradation is dependent on PV cells and their susceptibility to PID. The question is what negative voltage potential can cause PID degradation in PV modules with PID prone PV cells.

Update Information

- How much voltage does a photovoltaic panel have at 18 volts

- 18V photovoltaic panel output voltage

- Voltage and current of photovoltaic panel group

- What is the voltage of an 11 kW photovoltaic panel

- Voltage 20v photovoltaic panel

- 320w photovoltaic panel voltage

- What is the output voltage of a 550w single crystal photovoltaic panel

- What is the voltage and current of a 550w photovoltaic panel

- 680 Photovoltaic panel power generation voltage

- What is the output voltage of the 660 photovoltaic panel

- Photovoltaic panel current and voltage parameters

- What is the voltage of 6V photovoltaic panel

- The output voltage of the photovoltaic panel becomes low

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.