Breaking Down Photovoltaic Panel Construction Labor Costs

Why Labor Costs Matter in Solar Farm Development Picture this: A 500MW solar farm needs enough photovoltaic panels to cover 3,000 football fields. While the gleaming silicon gets all

Platts Solar Module Price Assessments

Jul 8, 2024 · Platts, part of S&P Global Commodity Insights, has observed strong interest in transparent solar module pricing following the exponential growth in the manufacture, trade

Solar Panel Manufacturing Plant Project Report 2024:

Apr 16, 2024 · Energy & Environment Industry Today Solar Panel Manufacturing Plant Project Report 2024: Manufacturing Process, Materials Cost and Requirements A solar panel,

Understanding Photovoltaic Panels Price Trends in China

Dec 30, 2024 · This article delves into the current state of photovoltaic panel prices in China, exploring the factors driving these changes, the technical features of solar panels, and the

Cost Breakdown of a Solar Panel: From Manufacturing to

Feb 23, 2024 · This article provides an in-depth analysis of the costs associated with solar panels, including manufacturing expenses, marketing and distribution efforts, regulatory compliance,

Photovoltaic Panels Cost in India 2025 | Solar System Price

Jun 23, 2025 · Wondering how much photovoltaic panels cost in India? This 2025 guide covers pricing, panel types, and key factors that affect solar panel system costs.

Analysis Of Photovoltaic Module Price Trends And Industry

Dec 31, 2024 · The cost of photovoltaic modules is primarily composed of solar cells, glass, encapsulation film, and labor expenses. In recent years, with intensified competition in the

Solar Panel Cost In 2025: It May Be Lower Than

Jul 31, 2025 · Solar panels are just 12% of the total cost of a solar panel installation. Federal and state solar incentives significantly lower the cost of

How Much Do Photovoltaic Panels Cost In 2024?

Jan 16, 2025 · The cost of solar panels ranges anywhere from $8,500 to $30,500, with the average 6kW solar system falling around $12,700. Solar panel prices vary based on where

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · Photovoltaic modules, or solar modules, are devices that gather energy from the sun and convert it into electrical power through the use of semiconductor-based cells. A

How Much Does it Cost to Produce Solar Panels and Modules

Jul 10, 2023 · Uncover solar panel manufacturing processes and expenses, discover what technological advancements make a difference, and learn how the costs can be reduced in

Solar (photovoltaic) panel prices

Jun 24, 2025 · IRENA presents solar photovoltaic module prices for a number of different technologies. Here we use the average yearly price for technologies ''Thin film a-Si/u-Si or

6 FAQs about [Unit price of finished photovoltaic solar panels]

How much does a solar panel cost?

Average EXW prices from distributors for residential solar panels are reported between €0.125/W and €0.100/W, depending on the volumes. US DDP: The spot price for TOPCon utility-scale modules DDP US rose this week from 0.71% to $0.284/W.

What factors affect the cost of photovoltaic modules?

1. Cost Factors Driving Price Fluctuations The cost of photovoltaic modules is primarily composed of solar cells, glass, encapsulation film, and labor expenses.

Why do solar modules cost so much?

However, as the primary cost component of photovoltaic modules, the price of solar cells plays a decisive role in module pricing. Due to the oversupply of polysilicon in earlier periods, prices have been under sustained pressure since 2023, even falling below cost levels in the first half of 2024.

How much do solar panels cost in Europe?

While Germany promotes rooftops and balcony applications, Italy focuses on smaller projects and Eastern Europe drives on bigger size solar installations. Average EXW prices from distributors for residential solar panels are reported between €0.125/W and €0.100/W, depending on the volumes.

Will price fluctuations affect the photovoltaic module market?

As the global energy transition accelerates, the photovoltaic (PV) industry, as a key component of renewable energy, continues to attract significant attention for its promising development prospects. However, price fluctuations in the photovoltaic module market remain a critical factor influencing the industry’s growth.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

Update Information

- What is the price of photovoltaic solar panels

- Price of photovoltaic solar panels

- Price of a photovoltaic solar panel

- Solar photovoltaic panels are hot in Hanoi

- Prices of solar photovoltaic panels sold in Japan

- Danish solar photovoltaic solar panels

- North Korea sells photovoltaic solar panels

- Guatemala City photovoltaic base has solar panels

- Solar photovoltaic panel 8 kilowatt price

- Wholesale price of polysilicon photovoltaic panels

- Beirut Photovoltaic Panels Greenhouse Solar Energy

- Rooftop photovoltaic panels for solar power generation

- Photovoltaic requires solar panels

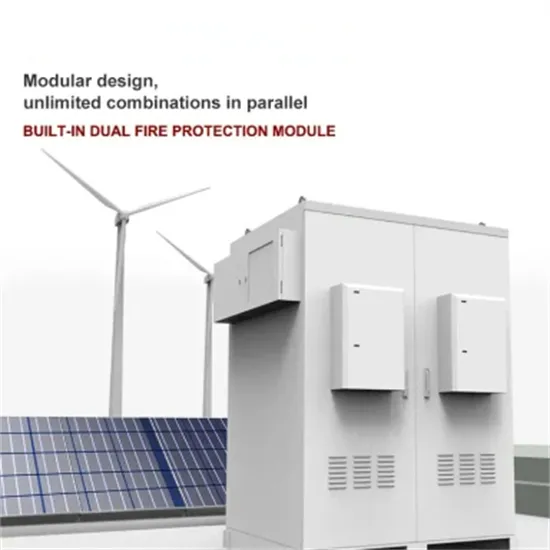

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.