A comparative study energy consumption and costs of battery

Mar 1, 2016 · Single reduction, DCT and CVT based battery electric vehicle models are compared. Shifting schedules for two-speed DCT and simplified CVT are optimized. Up to 14%

(PDF) Multi-Speed Gearboxes for Battery Electric Vehicles: Current

Nov 2, 2021 · Performance vehicles, light to heavy-duty trucks, and buses may especially benefit from multi-speed gearboxes due to their high torque and power requirements. This paper

How Maruti Suzuki Grand Vitara''s hybrid system

Jul 22, 2022 · The Intelligent Electric Hybrid system combines two power sources - a 1.5-litre combustion engine and an electric motor that is powered by a

The application of hybrid energy storage system with

Sep 15, 2019 · As part of the response to the above barriers, an electrified continuously variable transmission (CVT) is proposed along with HESS for BEV in this study. The improvements of

Review of Electronic-continuously Variable Transmission

This E-CVT system is mainly composed of three clutches, two planetary gears, two machines, two converters and a battery pack. By means of engaging or disengaging different clutch

CVT-Srvi New Pack Bateria Wholesale Mobile Phone Lithium Battery

Jul 3, 2025 · For X MAX Rechargeable No Size Small Features Enduring, Li-ion Battery, Aging Test Power Source Electric Capacity 100% Full Capacity Cycle Time More Than 500 Times

DCT Transmission Assembly Line_Transmission Intelligent

Demonstration product: 7 speed dual clutch transmission assembly line. Product info: the line includes shaft gear line assembly, shaft package assembly, housing press, main assembly line

ALL NEW SWIFT HYBRID

May 24, 2024 · CVT GEARBOX Suzuki''s CVT powertrain is fitted as optional equipment on both model grades and is combined with the new 1.2-litre three cylinder Mild Hybrid powertrain. The

2021 Honda Accord & Accord Hybrid Specifications & Features

Oct 12, 2020 · 2021 Honda Accord Specifications & Features[1] 192 @ 5500 rpm (SAE net), 252 @ 6500 rpm (SAE net), 143 @ 6200 rpm (SAE net) [2] 192 lb-ft @ 1600-5000 rpm (SAE net),

transmission lithium battery Latest Top Selling

transmission lithium battery is the latest best seller on the shelves. If you buy transmission lithium battery, you can enjoy the latest discount,freight reduction and subsidy. 去哪儿购买变速器锂

Honda CR-V hybrid powertrain explained in

Oct 8, 2018 · In fact, the car gets a 2-litre i-VTEC petrol engine, an electric motor and a lithium ion battery pack. The maximum output is 185bhp with torque of

Comparing of single reduction and CVT based

May 5, 2021 · In this paper, a structure simplified and gear ratio rearranged CVT based EV model is proposed and demonstrated. A smaller motor and battery pack are selected in model,

Understanding Lithium Ion Battery Packs: Types, Uses, and

Feb 13, 2025 · Lithium ion battery packs are integral to modern technology and sustainable energy solutions. By understanding the different types, their uses, and adhering to safety

Energy Efficiency Analysis and Comparison of

Aug 28, 2010 · The results show that with an optimized shifting strategy compared to a prescribed strategy using a Manual Transmission (MT) a maximum energy saving of 6% is possible. The

Transmission Ratio Design for Electric Vehicles via

Jan 23, 2023 · ologies: a continuously variable transmission (CVT) and a fixed gear transmission (FGT). We performed a numerical case study to show the effectiveness of our analytical

A comparative study energy consumption and costs of battery

Mar 1, 2016 · To do so a generic battery electric vehicle is modelled in Matlab/Simulink® to predict motor efficiency and energy consumption for single reduction, two speeds Dual Clutch

锂离子电池PACK知识全面讲解

电动两轮车锂电池PACK基本结构 两轮车锂电池PACK的主要硬件部件包括:防火外壳、LED显示屏(仅用于电池包部分)、智能BMS、电芯、电芯座、密封

Lithium-ion battery packs | VARTA AG

6 days ago · VARTA''s Application Specific Batteries offer you quicker design and integration and lower total cost of ownership. With high availability, certification included and matching

6 FAQs about [Cvt gearbox lithium battery pack]

Why is a CVT the least efficient gearbox type?

an ICE vehicle, causing further loss. All of these sources of loss lead to the CVT being the least efficient gea rbox type. investigate CVTs for EV applications , , , . speeds can be infinite . The planetary gearset can be gearset for the parallel configuration (Fig. 2 (f)). The range of equations for the gearbox .

How does a CVT transmission work?

To ensure that vehicles can accelerate to high speeds and be brought to a standstill automatically and safely, even without an active driver, the use of electronically controlled automatic transmissions is essential. In a CVT (continuously variable transmission), the pushbelt transmits the engine output to the drive axle.

What is a continuously variable transmission (CVT)?

Specific to continuously variable transmissions (CVT), the torque converter and hydraulic system can be removed, which is the most inefficient and complicated component. Furthermore, the infinite number of transmission ratios allows motor to always run at its optimum speed.

What is a gear E-CVT system?

The gear E-CVT system can be sorted into two cate- gories, according to the power split manner performed by planetary gears [Miller, 2006]. The first category can be named as input power split, which is adopted by Toyota and Ford. And the second category can be called compound power split, which is adopted by GM-Allison.

Which type of gearbox is best for EVs?

Since EVs typically points of range could be gained with a multi-speed gearbox. using production electric drivetrains as a benchmark. VI. C ONCLUSION vehicles. Most of the traditional gearbox types used for for EVs. AMTs, I-AMTs, DCTs, and CVTs show th e most promise.

How many optimal gear ratio values can a single CVT cover?

(23) optimal gear ratio value. Thereby, it can be observed that more than 80 % of the gear ratio values are below 6, which could be covered by a single CVT, even tough the machine was designed by the OEM with an FGT. III.

Update Information

- Basseterre lithium battery battery pack manufacturer

- Sucre 40a lithium battery pack

- Ukrainian 12v lithium battery pack

- Residual value of lithium battery pack

- Backup energy storage lithium iron phosphate battery pack

- 48v lithium battery pack has large self-discharge

- Kyrgyzstan custom lithium battery pack

- 18V photovoltaic energy storage cabinet battery lithium battery pack

- Foldable lithium battery pack

- Lithium battery pack consists of several cells

- Kwh lithium battery pack

- Argentina electric stacker lithium battery pack

- Tirana 21700 lithium battery pack manufacturer

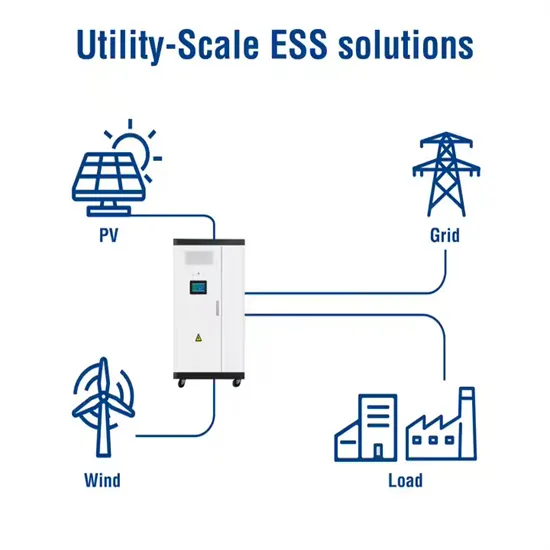

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

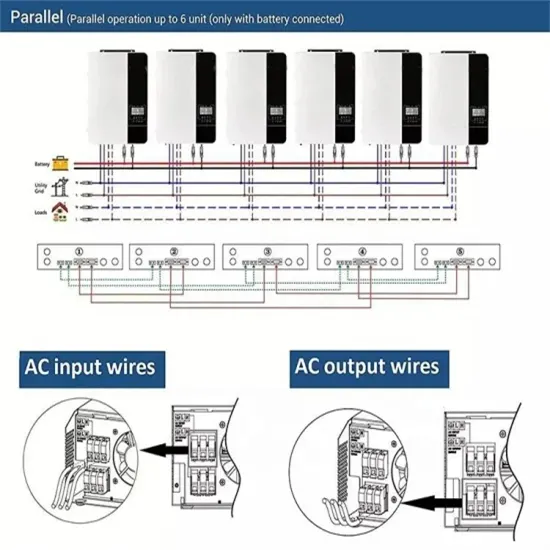

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.